Supported vanadium-chromium double-center composite catalyst as well as preparation method and application thereof

A composite catalyst and catalyst technology, applied in the field of chromium double-center composite catalyst and its preparation, and supported vanadium, which can solve the problems of the preparation method and application of olefin polymerization catalysts that have not been disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

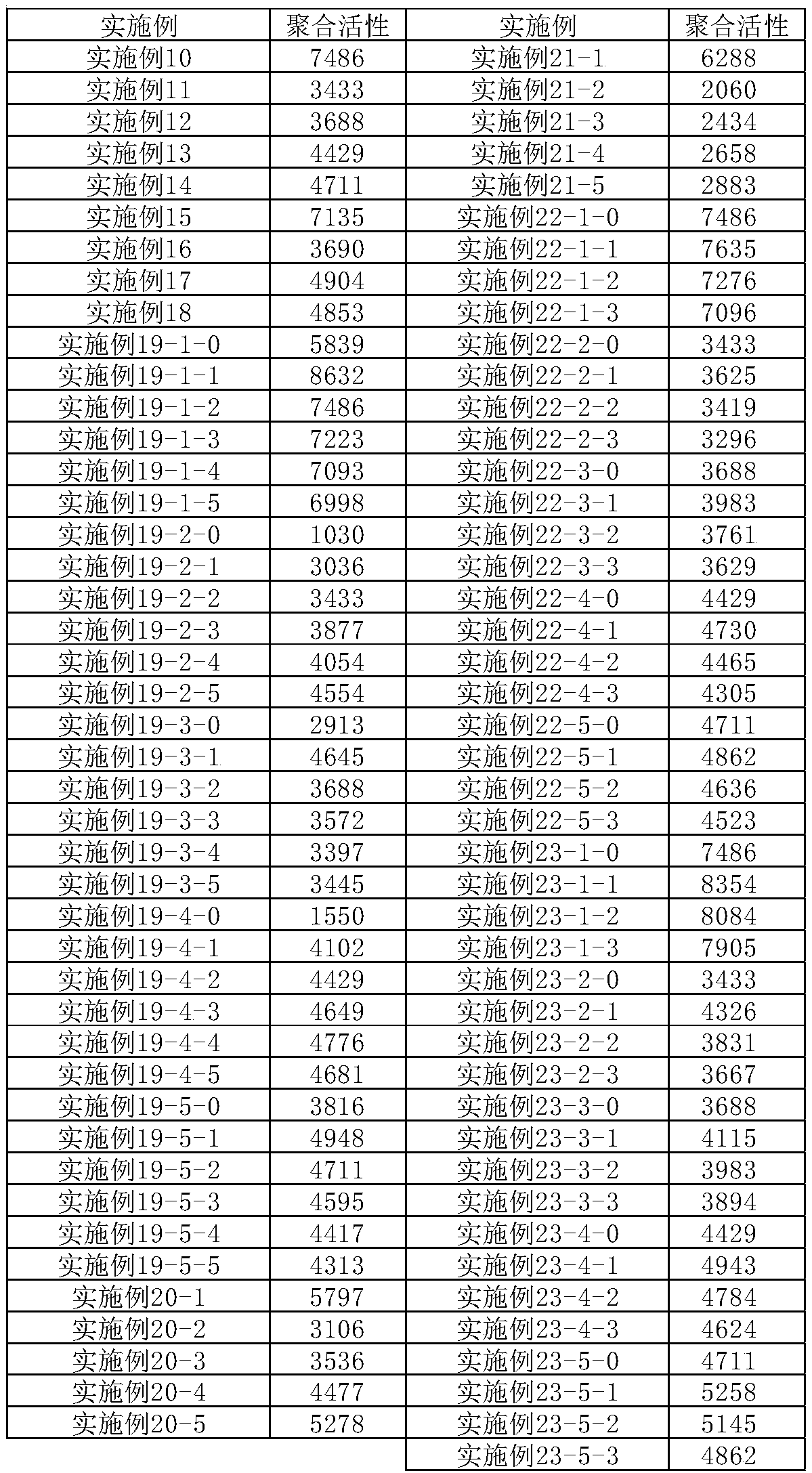

Examples

Embodiment 1

[0121] 10gSiO 2 / Al 2 o 3 (The pore volume is 1.5-1.7cm 3 / g, the surface area is 400-500m 2 / g) immersed in the aqueous solution of ammonium sulfate, vanadyl oxalate and chromium nitrate (according to the total weight of the catalyst, the loading of sulfur, vanadium and chromium is respectively 3wt%, 0.48wt% and 1wt%), 40 ℃ oil Stir and impregnate continuously under the bath for 5 hours, then heat up to 120°C and dry for 5 hours, then transfer to 120°C oven and dry for 6 hours; place the impregnated material in a quartz fluidized bed for roasting and activation, keep it in high-purity air at 500°C for 4 hours, and the roasted product is finally in The temperature was naturally lowered and cooled under nitrogen, and the obtained catalyst was preserved for later use.

Embodiment 2

[0123] 10gSiO 2 / TiO 2 (The pore volume is 1.1-1.4cm 3 / g, the surface area is 350-400m 2 / g) immersed in an aqueous solution of ammonium sulfate and vanadyl oxalate (according to the total weight of the catalyst, the loadings of sulfur and vanadium are respectively 3wt% and 0.48wt%), continuously stirred and impregnated in an oil bath at 40°C for 5h, and then Heat up to 120°C for 5 hours, then transfer to 120°C oven for 6 hours; place the impregnated material in a quartz fluidized bed for calcination and activation, keep it in high-purity air at 500°C for 4 hours, and finally cool the calcined product naturally under nitrogen, then in Transfer to a two-necked flask under nitrogen protection, and then configure a certain concentration of bistriphenylsilane chromate (synthetic method with reference to "Wang Jun, Li Yun, Li Cuiqin, etc. Research on the synthesis process of bistriphenylsilane chromate [J].Chemical Industry and Engineering, 2012,29(1):21-25 ") n-hexane solution...

Embodiment 3

[0125] 10gSiO 2 / ZnO 2 (The pore volume is 1.1-1.3cm 3 / g, the surface area is 300-400m 2 / g) immersed in an aqueous solution of ammonium sulfate and vanadyl oxalate (according to the total weight of the catalyst, the loadings of sulfur and vanadium are respectively 3wt% and 0.48wt%), continuously stirred and impregnated in an oil bath at 40°C for 5h, and then Heat up to 120°C for 5 hours, then transfer to 120°C oven for 6 hours; place the impregnated material in a quartz fluidized bed for calcination and activation, keep it in high-purity air at 500°C for 4 hours, and finally cool the calcined product naturally under nitrogen, then in Transfer to a two-necked flask under the protection of nitrogen, and then configure a certain concentration of bisindenyl chromium (refer to "FREDERICK J.KAROL, WILLIAML.MUNN, GEORGE L.GOEKE, et al.Supported Bis(indenyl)-and Bis( fluorenyl)-Chromium Catalysts for EthylenePolymerization.JOURNAL OF POLYMER SCIENCE.Vol.16,771-778(1978)") n-hexane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com