Preparation method of aluminum alloy coiled material for high pressure helical weld pipe

A technology of spiral welded pipe and aluminum alloy, which is applied in the field of aluminum alloy manufacturing, can solve the problems that the strength and toughness cannot match the use requirements at the same time, the electrical conductivity of the spiral welded pipe cannot be satisfied, and the welding defects of the spiral welded pipe, etc., to achieve guaranteed strength and mechanical properties. The effect of ensuring crimp solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing aluminum alloy coils for high-pressure spiral welded pipes, comprising the following steps:

[0027] A. Ingredients: Calculate the amount of each aluminum alloy raw material used for the preparation of high-pressure spiral welded pipes and prepare the aluminum alloy raw material according to the ratio. The ratio of the mass percentage of each element of the aluminum alloy raw material is as follows:

[0028] element Si Fe Cu mn Mg Cr Zn Ti Impurities Al content 0.046 0.109 0.002 0.004 2.603 0.024 0.006 0.009 0.15 margin

[0029] B. Melting and casting: Add the prepared aluminum alloy raw materials into the smelting furnace and mix them evenly to melt them into liquid aluminum alloys. After standing still, refining, slag removal, online degassing, and filtering processes, the liquid aluminum alloys are melted and cast into aluminum alloys. For ingot casting, the melting temperature is 730-750°C, the re...

Embodiment 2

[0036] A method for preparing aluminum alloy coils for high-pressure spiral welded pipes, comprising the following steps:

[0037] A. Ingredients: Calculate the amount of each aluminum alloy raw material used for the preparation of high-pressure spiral welded pipes and prepare the aluminum alloy raw material according to the ratio. The ratio of the mass percentage of each element of the aluminum alloy raw material is as follows:

[0038] element Si Fe Cu mn Mg Cr Zn Ti Impurities Al content 0.036 0.119 0.003 0.001 2.613 0.023 0.006 0.009 0.15 margin

[0039] B. Melting and casting: Add the prepared aluminum alloy raw materials into the smelting furnace and mix them evenly to melt them into liquid aluminum alloys. After standing still, refining, slag removal, online degassing, and filtering processes, the liquid aluminum alloys are melted and cast into aluminum alloys. For ingot casting, the melting temperature is 730-750°C, the re...

Embodiment 3

[0046] A method for preparing aluminum alloy coils for high-pressure spiral welded pipes, comprising the following steps:

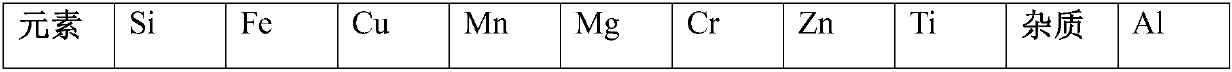

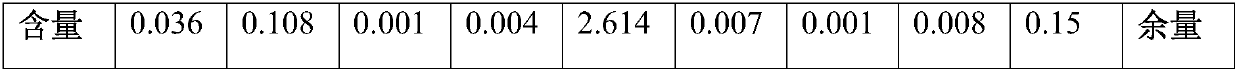

[0047] A. Ingredients: Calculate the amount of each aluminum alloy raw material used for the preparation of high-pressure spiral welded pipes and prepare the aluminum alloy raw material according to the ratio. The ratio of the mass percentage of each element of the aluminum alloy raw material is as follows:

[0048] element Si Fe Cu mn Mg Cr Zn Ti Impurities Al content 0.046 0.089 0.002 0.004 2.643 0.025 0.006 0.009 0.15 margin

[0049] B. Melting and casting: Add the prepared aluminum alloy raw materials into the smelting furnace and mix them evenly to melt them into liquid aluminum alloys. After standing still, refining, slag removal, online degassing, and filtering processes, the liquid aluminum alloys are melted and cast into aluminum alloys. For ingot casting, the melting temperature is 730-750°C, the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com