Soldering process capable of regulating and controlling grain orientation and structure of tin soldered joint

A technology of grain orientation and welding process, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of poor grain orientation, failure, complex service environment of solder joints, etc., to achieve improved reliability and practicability Strong, fewer welding process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

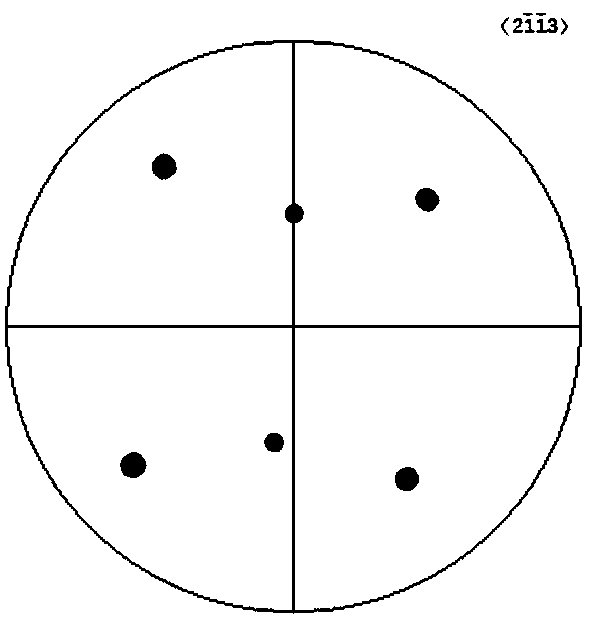

[0027] Step 1: Make 8 pads on the resin-based PCB, and deposit a layer of Co single crystal with a thickness of 10um by physical vapor deposition at each pad position. The pole figure of Co single crystal is as follows figure 1 shown;

[0028] Step 2: Uniformly coat a layer of flux on each deposited Co single crystal pad, and fix a solder ball with a diameter of 500 μm and a purity of 99.99% on the single crystal metal;

[0029] Step 3: Heat the heating plate to 300°C at a heating rate of 30°C / min. Place the resin-based PCB flat on the heating plate and keep it warm for 100s. Then clamp the PCB away from the heating plate and cool to room temperature. The welding is complete.

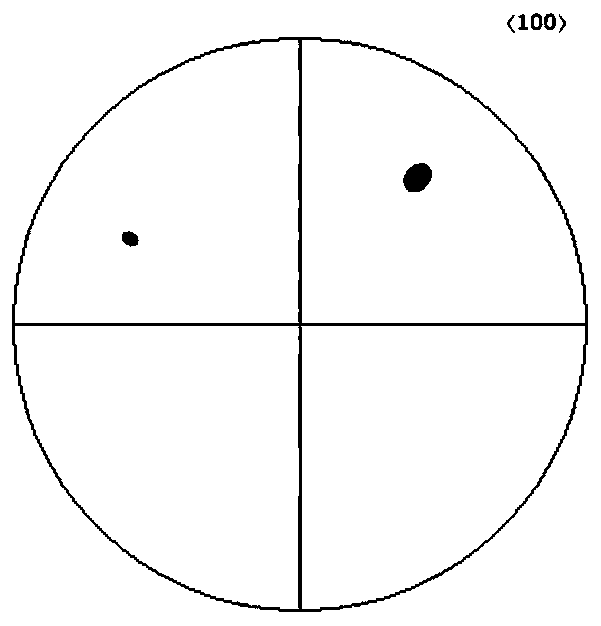

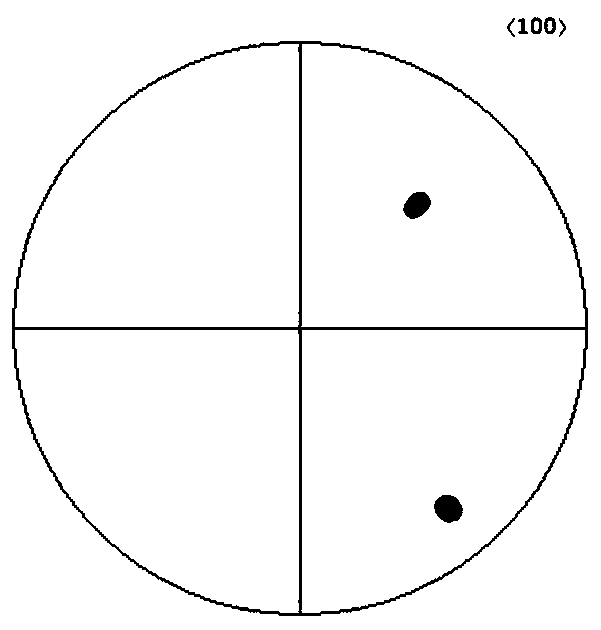

[0030] Electron backscattering (EBSD) tests were carried out on the 10 solder joints in the PCB boards soldered in step 3. The interface intermetallic compound CoSn in the first solder joint 3 The polar figure such as figure 2 As shown, the pole figure of βSn in the solder joint is as follows image...

Embodiment 2

[0032] Step 1: Deposit a layer of Pd single crystal with a thickness of 15um on the 5 pads of the resin-based PCB by physical vapor deposition;

[0033] Step 2: Uniformly coat a layer of flux on the deposited Pd single crystal, and fix SnAgCu solder balls with a diameter of 500 μm on the single crystal metal;

[0034] Step 3: Heat up the reflow soldering machine to 280°C with a heating rate of 40°C / min, place the single crystal substrate in the reflow soldering machine, keep it warm for 90s, take out the PCB board, and cool it to room temperature with the air, and the soldering is complete.

[0035] Perform EBSD tests on the 5 solder joints on the PCB board that have been soldered in step 3, and the pole figures are as follows Figure 4 As shown, the test results show that the measured solder joints are single crystal, and the grain orientation of βSn is obviously controlled.

Embodiment 3

[0037] Step 1: Deposit a layer of Co single crystal with a thickness of 15um on the 5 pads of the resin-based PCB by physical vapor deposition;

[0038] Step 2: uniformly coat a layer of flux on the deposited Co single crystal, and fix a solder ball with a diameter of 500 μm and a purity of 99.99% on the single crystal metal;

[0039] Step 3: Heat up the reflow soldering machine to 300°C with a heating rate of 60°C / min, put the resin-based PCB board in the reflow soldering machine, keep it warm for 80s, take out the PCB board, and cool it to room temperature with the air, and the soldering is completed.

[0040] The characterization of the experimental results: such as Figure 5 Scanning electron microscope (SEM) pictures found that due to the influence of the Co single crystal substrate, the intermetallic compounds in the measured solder joints have obvious specific orientations, and the angle between the two specific orientations is 90°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com