Method for treating fluorine ions and chlorine ions in acidic wastewater solution

A technology for acidic wastewater and chloride ions, which is used in filtration treatment, chemical instruments and methods, heating water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

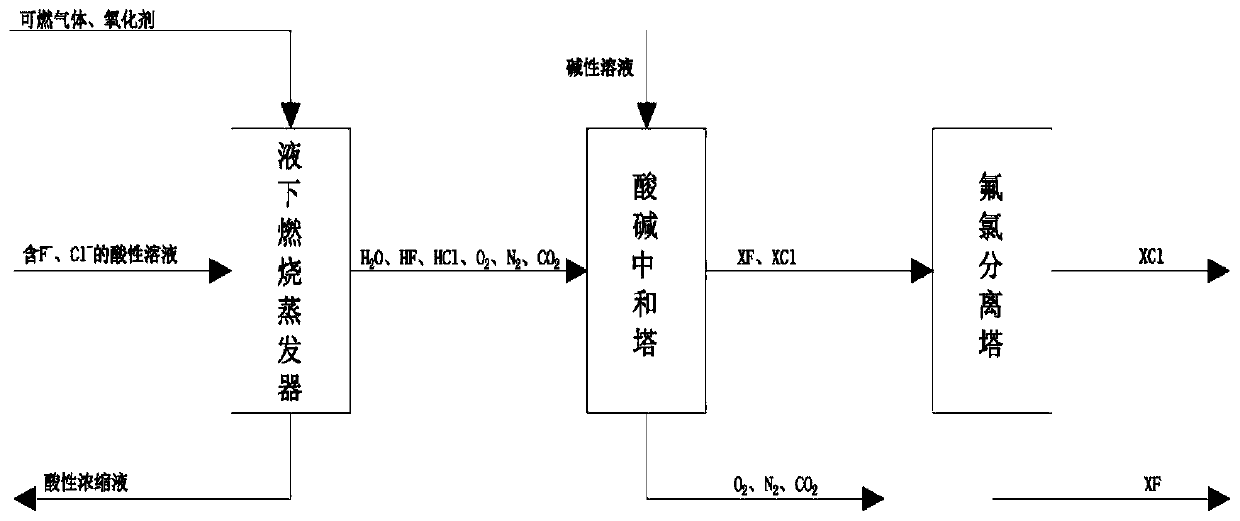

Method used

Image

Examples

Embodiment 1

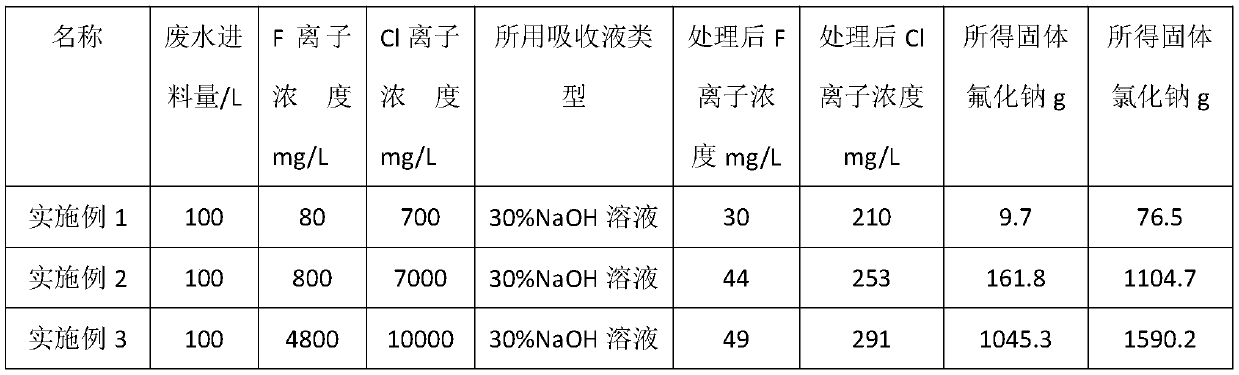

[0025] The indicators of the acidic wastewater solution selected in this embodiment are as follows: the fluoride ion concentration is 80 mg / L, and the chloride ion concentration is 700 mg / L. This acidic waste water solution is carried out the processing of following steps:

[0026] (1) Take 100L of acidic wastewater solution, and use a plunger metering pump to introduce it from the middle to the submerged combustion evaporator at a flow rate of 10L / min. After the solution is introduced, methane and air are mixed at a volume ratio of 1:12, then introduced into the submerged combustion evaporator at a flow rate of 100L / min, and the igniter is turned on for ignition and combustion. The heat generated by combustion is in direct contact with the acidic wastewater solution to evaporate and concentrate it, and the fluorine and chloride ions are in the form of HF and HCl gas and the H generated after combustion 2 O, O 2 , N 2 , CO 2 It is drawn from the upper part of the evaporato...

Embodiment 2

[0031] The wastewater used in this embodiment has a fluoride ion concentration of 800 mg / L and a chloride ion concentration of 7000 mg / L. Do the following steps:

[0032] (1) Take 100L of the above-mentioned acidic wastewater solution and introduce it from the middle part into the submerged combustion evaporator with a pump at a speed of 10L / min. Dimethyl ether and pure oxygen are introduced into the submerged combustion evaporator with a volume ratio of 1:6 and a flow rate of 100L / min, and the igniter is turned on for ignition and combustion. The heat generated by combustion is in direct contact with the acidic wastewater solution to evaporate and concentrate it, and the fluorine and chloride ions are in the form of HF and HCl gas and the H generated after combustion 2 O, O 2 , N 2 , CO 2 It is drawn from the upper part of the evaporator to the acid-base neutralization tower. The concentrated acidic solution is drawn from the bottom of the burner to the recovery unit. A...

Embodiment 3

[0036] The wastewater used in this embodiment has a fluoride ion concentration of 4800 mg / L and a chloride ion concentration of 10000 mg / L. Do the following steps:

[0037] (1) Take 100L of the above-mentioned acidic wastewater solution and introduce it from the middle part into the submerged combustion evaporator with a pump at a speed of 10L / min. Introduce butane and air into the submerged combustion evaporator with a volume ratio of 1:4 and a flow rate of 100L / min, and turn on the igniter for ignition and combustion. The heat generated by combustion is in direct contact with the acidic wastewater solution to evaporate and concentrate it, and the fluorine and chloride ions are in the form of HF and HCl gas and the H generated after combustion 2 O, O 2 , N 2 , CO 2 It is drawn from the upper part of the evaporator to the acid-base neutralization tower. The concentrated acidic solution is drawn from the bottom of the burner to the recovery unit. After testing, the fluori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com