Phase change energy absorbing polyurethane elastomer explosion-proof tank outer protection cover preparation method

A technology of polyurethane elastomer and outer protective cover, applied in the field of explosion-proof materials, can solve the problems of inability to achieve rapid movement, increase in weight, discount of application value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

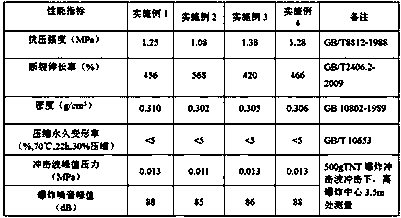

Examples

Embodiment 1

[0038] A preparation method of a phase-change energy-absorbing polyurethane elastomer explosion-proof tank outer protective cover, comprising the following steps:

[0039] (1) 48 parts by mass of polytetrahydrofuran polyol with a bifunctional molecular weight of 2000, 15 parts by mass of polyoxypropylene polyol EP330 with a trifunctional molecular weight of 5000, and 3.5 parts by mass of 1,4-butanediol, 0.25 parts by mass of H 2 O, 1.0 mass parts of A33, 0.01 mass parts of A33, 0.01 mass parts of AK-7730, 0.01 mass parts 12 , parts of catalyst, 15 parts by mass of MgSO4.7H 2 O and 15 parts by mass of Ni(NO 3 ) 2 .6H 2 O through the solid phase change powder filler of 400 mesh sieve, after accurately weighing according to the mass ratio, mix evenly to obtain the A component;

[0040](2) After reacting 50 parts by mass of diphenylmethane diisocyanate (MDI) and 50 parts by mass of polytetrahydrofuran polyol with a bifunctional molecular weight of 2000 at 80-90°C for 4-6 hour...

Embodiment 2

[0044] A preparation method of a phase-change energy-absorbing polyurethane elastomer explosion-proof tank outer protective cover, comprising the following steps:

[0045] (1) Mix 48 parts by mass of polycaprolactone polyol with bifunctional molecular weight of 2000, 15 parts by mass of polyoxypropylene polyol EP330 with trifunctional molecular weight of 5000, and 3.5 parts by mass of 1,4-butanediol alcohol, 0.25 parts by mass of H 2 O, 1.0 mass parts of A33, 0.01 mass parts of A33, 0.01 mass parts of AK-7730, 0.01 mass parts 12 , parts of catalyst, 15 parts by mass of MgSO4.7H 2 O and 15 parts by mass of Ni(NO 3 ) 2 .6H 2 O through the solid phase change powder filler of 400 mesh sieve, after accurately weighing according to the mass ratio, mix evenly to obtain the A component;

[0046] (2) React 50 parts by mass of diphenylmethane diisocyanate (MDI) with 50 parts by mass of polycaprolactone polyol with bifunctional molecular weight of 2000 at 80-90°C for 4-6 hours, then...

Embodiment 3

[0050] A preparation method of a phase-change energy-absorbing polyurethane elastomer explosion-proof tank outer protective cover, comprising the following steps:

[0051] (1) 40 parts by mass of polytetrahydrofuran polyol with 2-functionality molecular weight of 2000, 8 parts by mass of polytetrahydrofuran polyol with 2-functionality molecular weight of 1000, 15 parts by mass of polytetrahydrofuran polyol with 3-functionality molecular weight of 5000 Alcohol EP330, with 3,0 parts by mass of 1,4-butanediol, 0.25 parts by mass of H 2 O, 1.0 mass parts of A33, 0.01 mass parts of A33, 0.01 mass parts of AK-7730, 0.01 mass parts 12 , parts of catalyst, 15 parts by mass of MgSO4.7H 2 O and 15 parts by mass of Ni(NO 3 ) 2 .6H 2 O through the solid phase change powder filler of 400 mesh sieve, after accurately weighing according to the mass ratio, mix evenly to obtain the A component;

[0052] (2) After reacting 50 parts by mass of diphenylmethane diisocyanate (MDI) and 50 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com