Styrene volatilization inhibitor based on cholesterol derivative, and preparation method thereof

A technology of derivatives and cholesterol, which is applied in the field of styrene volatilization inhibitor and its preparation, can solve the problems of increasing the cost and high price of unsaturated resin, and achieve excellent styrene volatilization inhibition effect, guarantee of health, and fast drying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The composition of the styrene volatilization inhibitor of this embodiment is shown in the following table:

[0023] Specific components Weight / g Cholesterol derivative C166 Xylene30 54# Paraffin4

[0024]

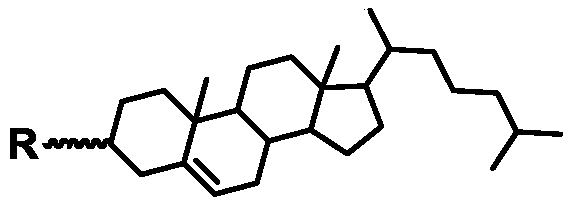

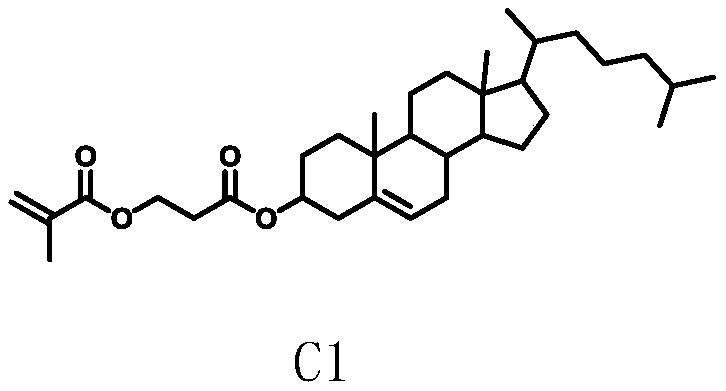

[0025] (1) Add the cholesterol derivative (chemical structural formula as shown in C1) and xylene into a reactor equipped with a heating device and a stirring device, turn on the stirring, and stir evenly at an ambient temperature of 25°C;

[0026] (2) Add the crushed 54# paraffin to the reaction kettle and continue to stir evenly at 45°C;

[0027] (3) Filter the above materials with a 200-mesh filter bag to obtain the styrene volatilization inhibitor.

Embodiment 2

[0029] The composition of the styrene volatilization inhibitor of this embodiment is shown in the following table:

[0030] Specific components Weight / g Cholesterol derivative C270 Styrene24 52# Paraffin6

[0031]

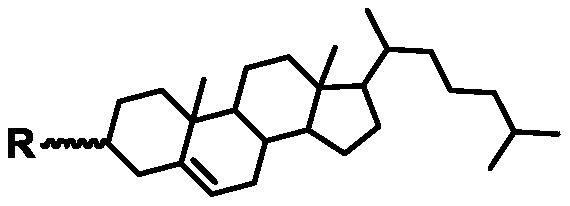

[0032] (1) Add the cholesterol derivative (chemical structural formula as shown in C2) and styrene into a reactor with a heating device and a stirring device, turn on the stirring, and stir evenly at an ambient temperature of 30°C;

[0033] (2) Add the crushed 52# paraffin to the reaction kettle and continue to stir evenly at 50°C;

[0034] (3) Filter the above materials with a 400-mesh filter bag to obtain the styrene volatilization inhibitor.

Embodiment 3

[0036] The composition of the styrene volatilization inhibitor of this embodiment is shown in the following table:

[0037] Specific components Weight / g Cholesterol derivative C350 No. 120 solvent oil20 Diallyl phthalate30 paraffin0

[0038]

[0039] (1) Add cholesterol derivatives (chemical structure as shown in C3), solvent oil No. 120 and diallyl phthalate into a reactor with a heating device and a stirring device, turn on the stirring, and set it at 20°C Stir evenly at the ambient temperature;

[0040] (2) Filter the above materials with a 100 mesh filter bag to obtain the styrene volatilization inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com