Converter primary dust removal system colored smoke plume eliminating device

A technology of dust removal system and converter, which is applied in the manufacture of converters, climate sustainability, metal processing, etc., can solve the problems of large floor space, inaccessibility, secondary pollution sewage treatment, etc., achieves good condensation cooling effect, eliminates Effects of Corrosion Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

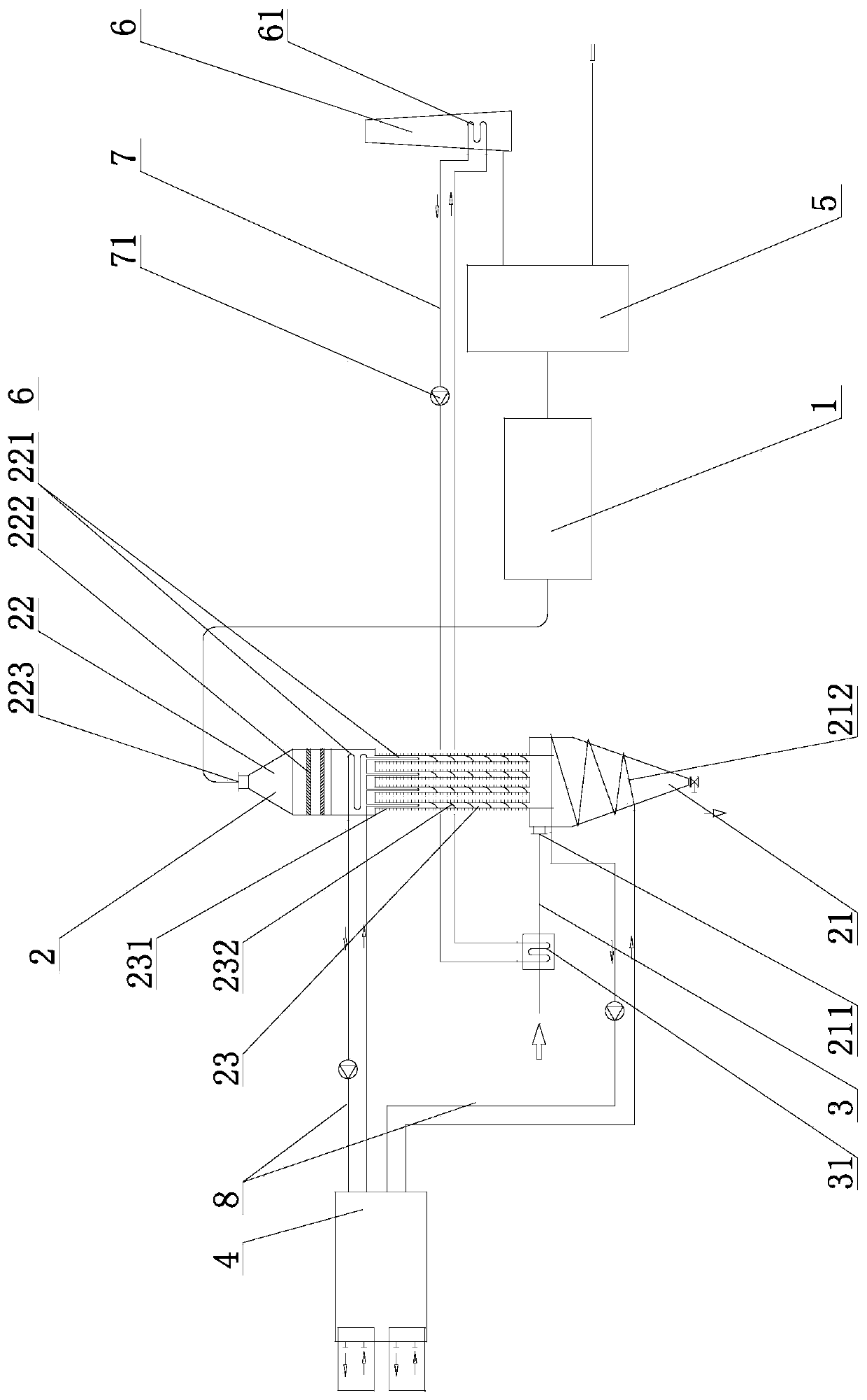

[0025] Such as figure 1 As shown, the colored plume elimination device of the primary dust removal system of the converter in this embodiment includes a saturated hot and humid flue gas condensation dehumidifier 2 provided on the front side of the fan 1 of the primary dust removal system of the converter, and the saturated hot and humid flue gas condensation dehumidifier 2 includes a lower condensation The chamber 21 and the upper condensation chamber 22, the upper condensation chamber 21 and the lower condensation chamber 22 are connected through several natural condensation pipes 23, and the side of the lower condensation chamber 21 is provided with a flue gas inlet 211, and the flue gas inlet 211 passes through the flue gas pipe 3 Connect the treatment device at the front end of the primary dust removal system of the converter, and install a cold water coil 212 on the outer wall of the lower condensation chamber 21, and install an insulation device outside the cold water coi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap