LED driving circuit, load control system, load system and control method

An LED driver and circuit technology, applied in energy-saving control technology, electric light source, electrical components, etc., can solve problems such as reducing system efficiency and increasing system loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

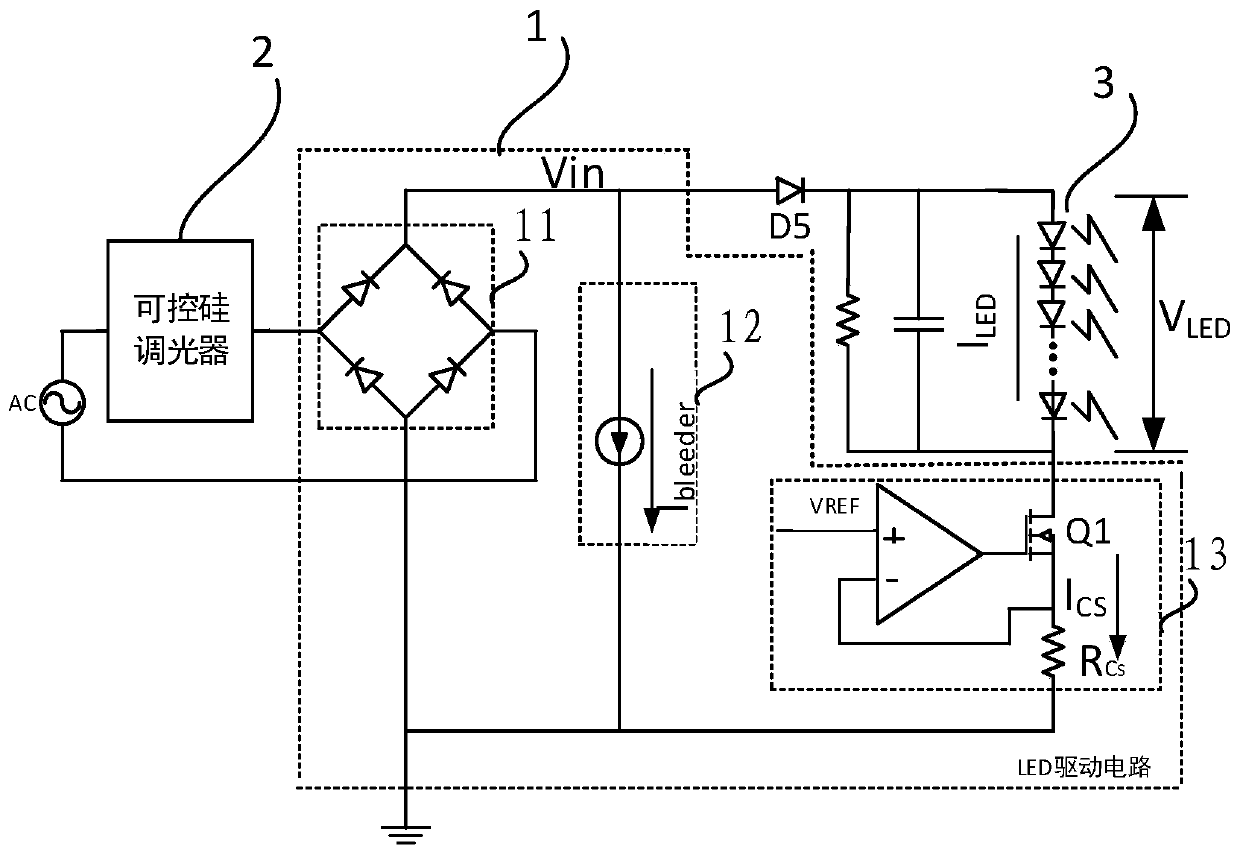

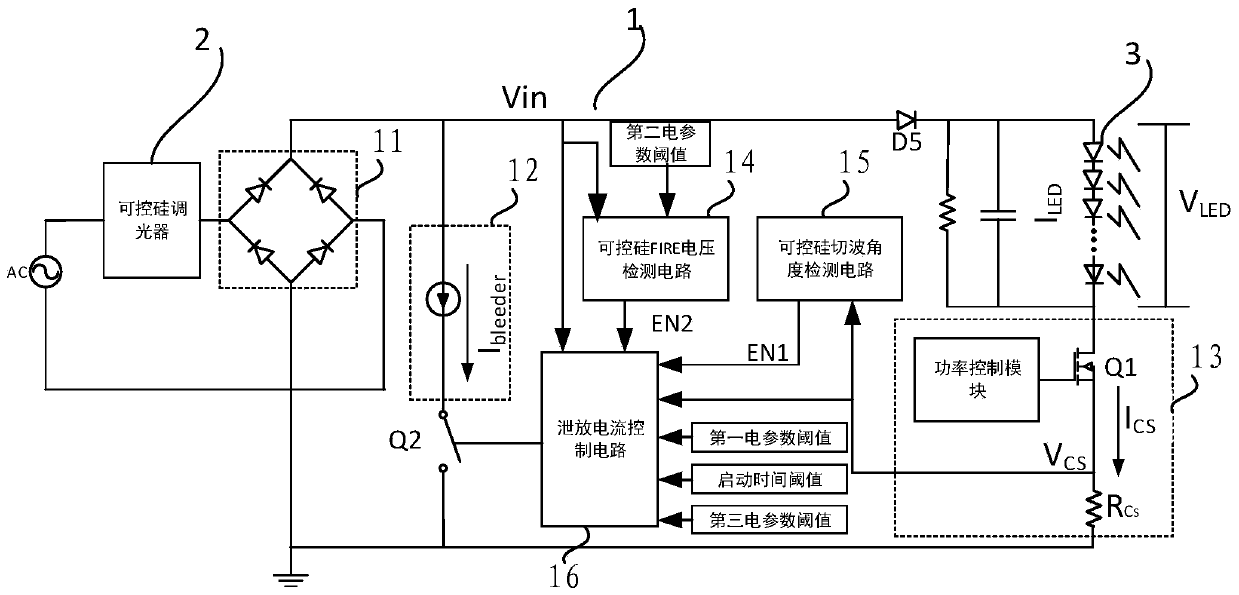

[0060] The present invention provides a LED driving circuit, referring to image 3As shown, the LED drive circuit 1 includes: rectifier circuit 11, discharge circuit 12, LED constant current control circuit 13, SCR FIRE voltage detection circuit 14, SCR wave cutting angle detection circuit 15 and discharge current control circuit 16;

[0061] The discharge circuit 12, the LED constant current control circuit 13 and the thyristor FIRE voltage detection circuit 14 are respectively connected to the rectifier circuit 11; the thyristor wave cutting angle detection circuit 15 is connected to the LED constant current control circuit 13; the discharge current control circuit 16 are respectively connected with the thyristor cutting wave angle detection circuit 15 and the thyristor FIRE voltage detection circuit 14;

[0062] The SCR wave cutting angle detection circuit 15 detects the first electrical parameter signal value representing the SCR wave cutting angle, compares it with the p...

Embodiment 2

[0127] Such as Figure 14 As shown, based on the same inventive concept, the embodiment of the present invention also provides an LED load control system, including: a thyristor dimmer 2, and at least one of the above-mentioned embodiment 1 connected in parallel with the thyristor dimmer 2 The LED driver circuit 1 described in .

[0128] Regarding the LED load control system in the above-mentioned embodiment, the specific way of performing operations of the thyristor dimmer and the LED driving circuit has been described in detail in the LED driving circuit of the first embodiment above, and will not be described in detail here Explain.

Embodiment 3

[0130] Such as Figure 14 As shown, based on the same inventive concept, the embodiment of the present invention also provides an LED load system, including: a thyristor dimmer 2, and at least one of the above-mentioned embodiment ones connected in parallel with the thyristor dimmer 1 The above LED driving circuit 1 and the LED load 3 connected to the LED driving circuit 1 .

[0131] Regarding the LED load system in the above-mentioned embodiment, the specific way of performing operations of the thyristor dimmer and the LED driving circuit has been described in detail in the LED driving circuit of the above-mentioned embodiment 1, and will not be elaborated here illustrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com