Building engineering material produced by means of sludge and production method of material

A technology of construction engineering and sludge, applied in the field of building materials, can solve the problem that the weather resistance, wear resistance stability and mechanical mechanical properties of materials need to be further improved, affect the appearance of products and painting performance, and have a greater impact on glass fiber shrinkage, etc. Problems, to achieve high promotion and application value, simple and easy production method, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

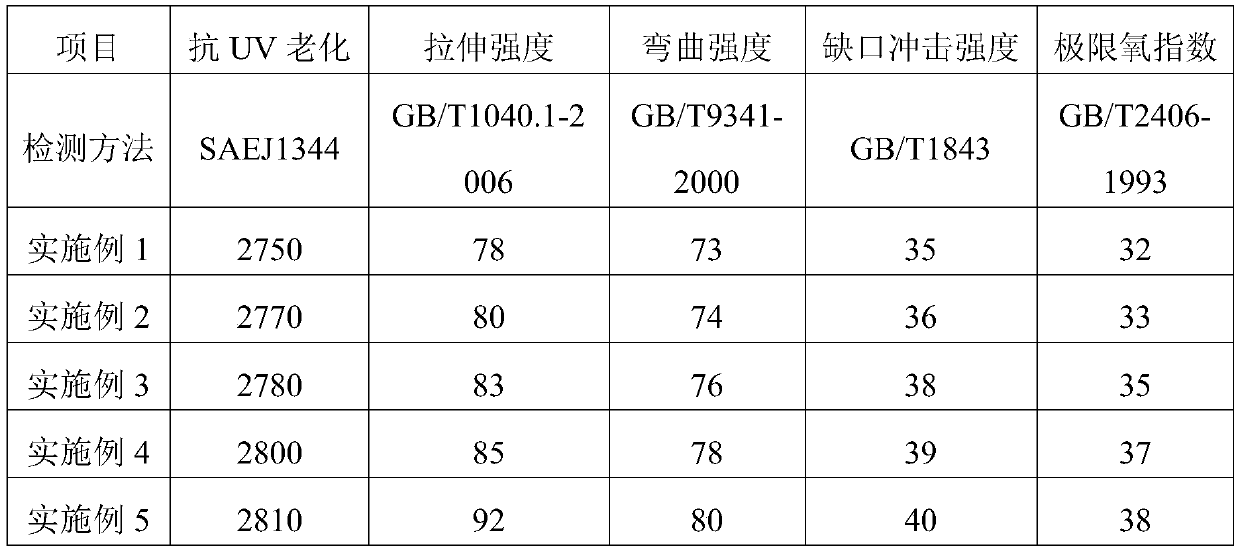

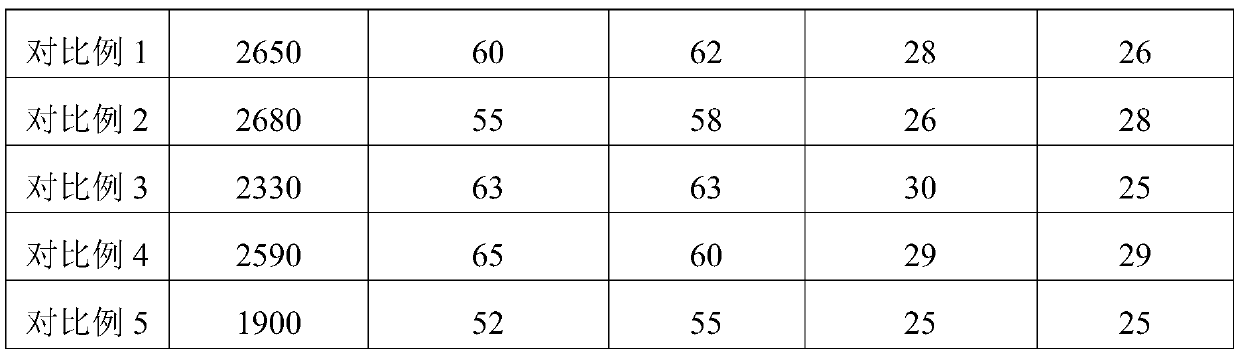

Examples

Embodiment 1

[0027] A construction engineering material produced from sludge, which is made of the following raw materials in parts by weight: 10 parts of sludge powder, 5 parts of nano-boron fiber, 2,4,5-trifluorophenylacrylic acid-terminated poly-3,3 80 parts of '-diselenide dipropionic acid 4,4'-diaminodiphenylsulfone amide, 5 parts of tetrazole-based silicon-containing fluorophenyl polymeric ester, 3 parts of titanium triisopropoxide methacrylate, azodiiso 1 part of nitrile.

[0028] The preparation method of the sludge powder comprises the following steps: the sludge is sequentially aerated, the pH value is adjusted to a pH of 6, and the sedimentation treatment is carried out, and then sent into an evaporation box, and the sludge in the sludge is baked by hot air. The water is evaporated to 10%, and extruded to form a solid soil block, and then the block sludge is crushed to 100 mesh by a pulverizer, then dried at 95°C, and finally subjected to high-temperature disinfection to obtain ...

Embodiment 2

[0033] A construction engineering material produced from sludge, which is made of the following raw materials in parts by weight: 13 parts of sludge powder, 6 parts of nano-boron fiber, 2,4,5-trifluorophenylacrylic acid-terminated poly-3,3 85 parts of '-diselenide dipropionic acid 4,4'-diaminodiphenyl sulfone amide, 6 parts of tetrazole-based silicon-containing fluorophenyl polymeric ester, 4 parts of titanium triisopropoxide methacrylate, azodiiso Heptanonitrile 1.5 parts.

[0034] The preparation method of the sludge powder comprises the following steps: the sludge is sequentially aerated, the pH value is adjusted to 6.5, and the sedimentation treatment is carried out, and then sent into the evaporation box, and the sludge in the sludge is baked by hot air. The water is evaporated to 12%, and extruded to form a solid soil lump, and then the lump sludge is crushed to 120 mesh by a pulverizer, then dried at 97°C, and finally subjected to high-temperature disinfection to obtain...

Embodiment 3

[0039] A construction engineering material produced from sludge, which is made of the following raw materials in parts by weight: 15 parts of sludge powder, 7.5 parts of nano-boron fiber, 2,4,5-trifluorophenylacrylic acid-terminated poly-3,3 90 parts of '-diselenide dipropionic acid 4,4'-diaminodiphenylsulfone amide, 7.5 parts of tetrazole-based silicon-containing fluorophenyl polymeric ester, 4.5 parts of titanium triisopropoxide methacrylate, tert-amyl peroxide Acetate tert-butyl ester 2 parts.

[0040] The preparation method of the sludge powder comprises the following steps: aerating the sludge in turn, adjusting the pH value to pH 7, sedimentation treatment, and then sending it into an evaporation box, and drying the sludge in the sludge by hot air The water is evaporated to 15%, and extruded to form a solid soil block, and then the block sludge is crushed to 150 mesh by a pulverizer, then dried at 99°C, and finally subjected to high-temperature disinfection to obtain slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com