Multi-valence-state vanadium oxide flexible electrode preparation method

A vanadium oxide and flexible electrode technology, which is applied in the field of multivalent vanadium oxide flexible electrode preparation, can solve problems such as difficult operation and complicated process flow, and achieve electrochemical performance improvement, safe and reliable process, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] One aspect of the present invention provides a method for preparing a multivalent vanadium oxide flexible electrode. In an exemplary embodiment of the method for preparing a multivalent vanadium oxide flexible electrode of the present invention, the preparation method may include:

[0026] Step S01, activating the carbon cloth to obtain activated carbon cloth.

[0027] In this embodiment, the method for activating the carbon cloth may include arranging the carbon in a container (for example, a reactor) filled with hydrogen peroxide for activation treatment. The temperature of the activation treatment may be 120°C to 200°C. Further, the temperature of the activation treatment may be 150°C-200°C. For example, it may be 180°C. The mass concentration of hydrogen peroxide can be 0.5%-24.5%. Further, the mass concentration of hydrogen peroxide may be 0.5%-20.0%. For example, it can be 3%. Appropriate activation temperature and hydrogen peroxide concentration are conduciv...

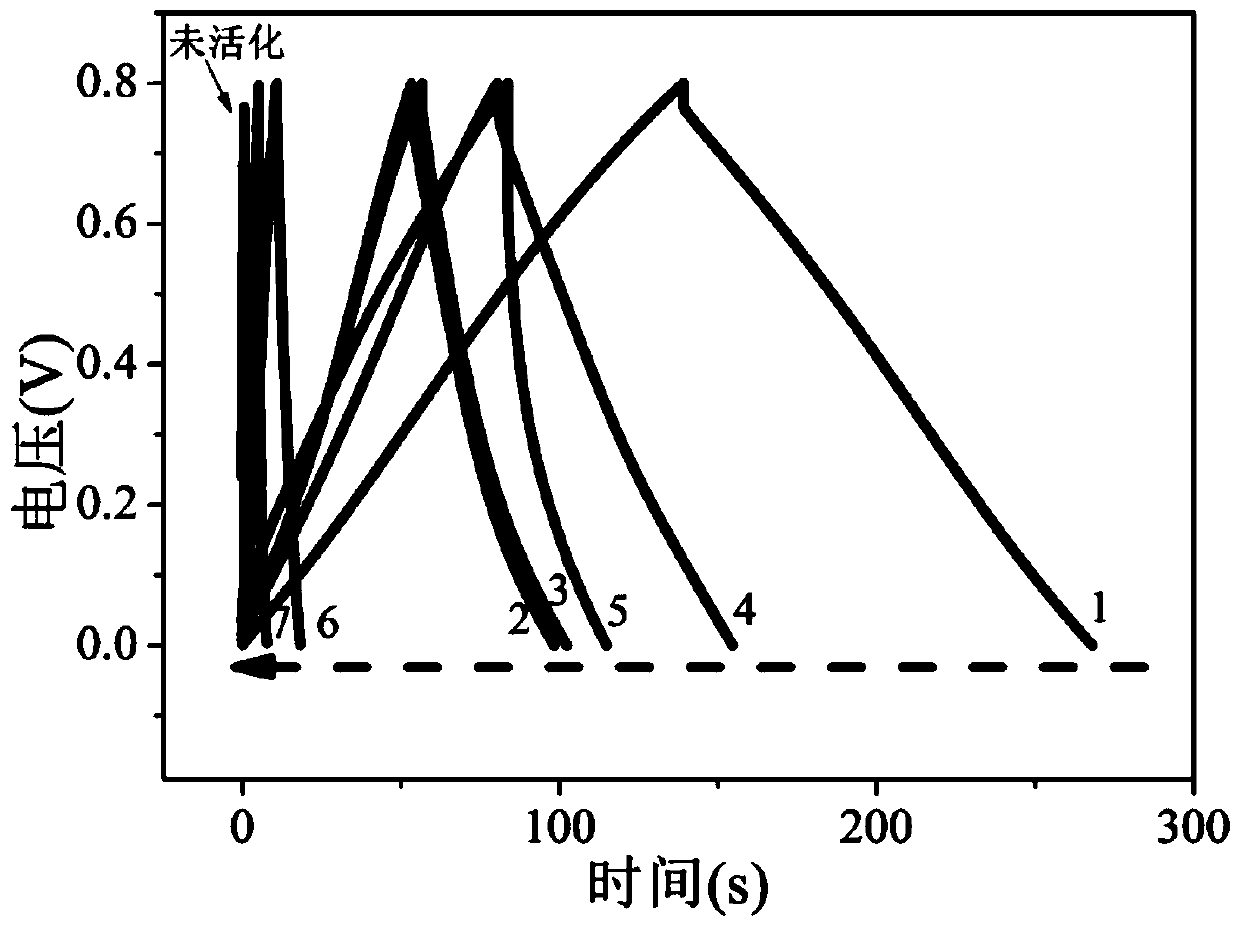

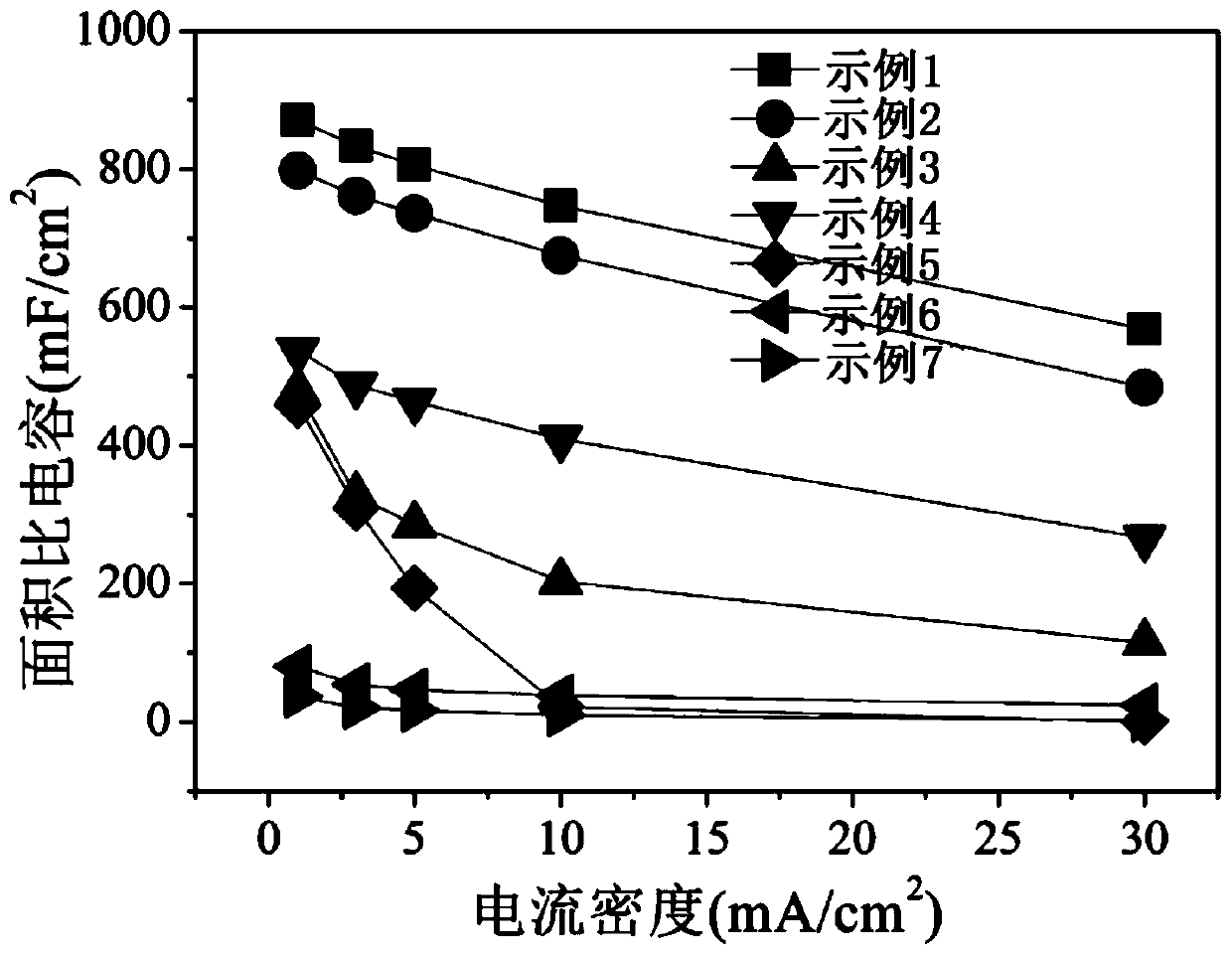

example 1

[0045] (1) The interception size is 2.5×6cm 2 , a commercial carbon cloth with a thickness of 350 μm, and then ultrasonically cleaned with a water / ethanol / nitric acid mixed solution, washed and dried.

[0046] (2) Put the carbon cloth cleaned in step (1) into the reactor, the concentration of hydrogen peroxide in the reactor is 3wt%, the reaction temperature is set to 200°C, and the reaction time is 12h.

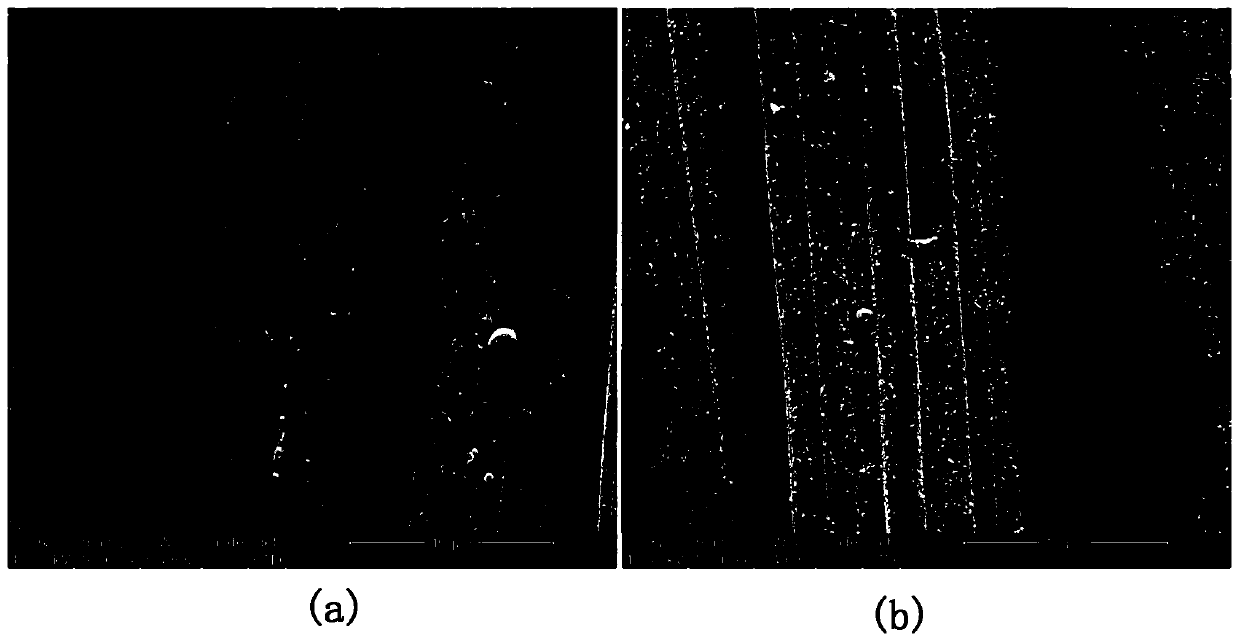

[0047] (3) After the reaction is finished, it is cooled to room temperature, washed and dried to obtain activated carbon cloth, such as figure 2 shown.

[0048] (4) Fix the activated carbon cloth obtained in step (3) on the wall of the beaker, and add ethylene glycol and metavanadate with a concentration of 21 mmol / L into the beaker.

[0049] (5) Put the sample obtained in step (4) into an oil bath at 120° C. and keep it warm for 2 hours under stirring until the reaction is completed.

[0050] (6) After the reaction is finished, the product of step (5) is washed and drie...

example 2

[0053] (1) The interception size is 2.5×6cm 2 , a commercial carbon cloth with a thickness of 350 μm, and then ultrasonically cleaned with a mixed solution such as water / ethanol / nitric acid, washed and dried.

[0054] (2) Put the carbon cloth cleaned in step (1) into the reactor, the concentration of hydrogen peroxide in the reactor is 12.7wt%, the reaction temperature is set to 200°C, and the reaction time is 12h.

[0055] (3) After the reaction is finished, wait for it to cool to room temperature, wash and dry to obtain activated carbon cloth.

[0056] (4) Fix the activated carbon cloth obtained in step (3) on the wall of the beaker, and add ethylene glycol and metavanadate with a concentration of 42mmol / L into the beaker.

[0057] (5) Put the sample obtained in step (4) into an oil bath at 200° C. and keep it under stirring for 5 hours until the reaction is completed.

[0058] (6) After the reaction is finished, the product of step (5) is washed and dried, and heat-preser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com