Silane modified biochar as well as preparation method and application thereof

A technology of silane modification and silane modifier, which is applied in the direction of chemical instruments and methods, water pollutants, and other chemical processes. Broad application prospects and moderate process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

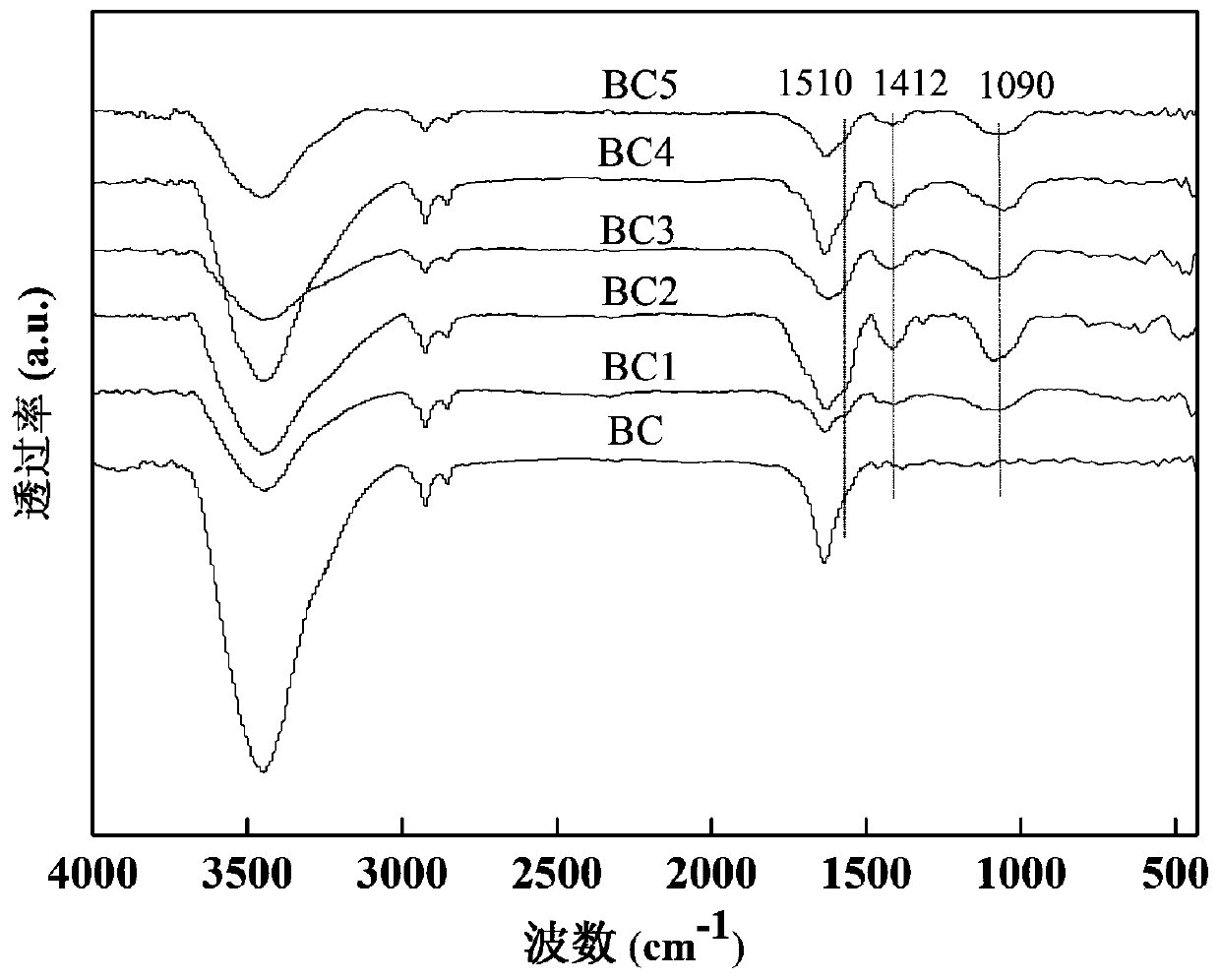

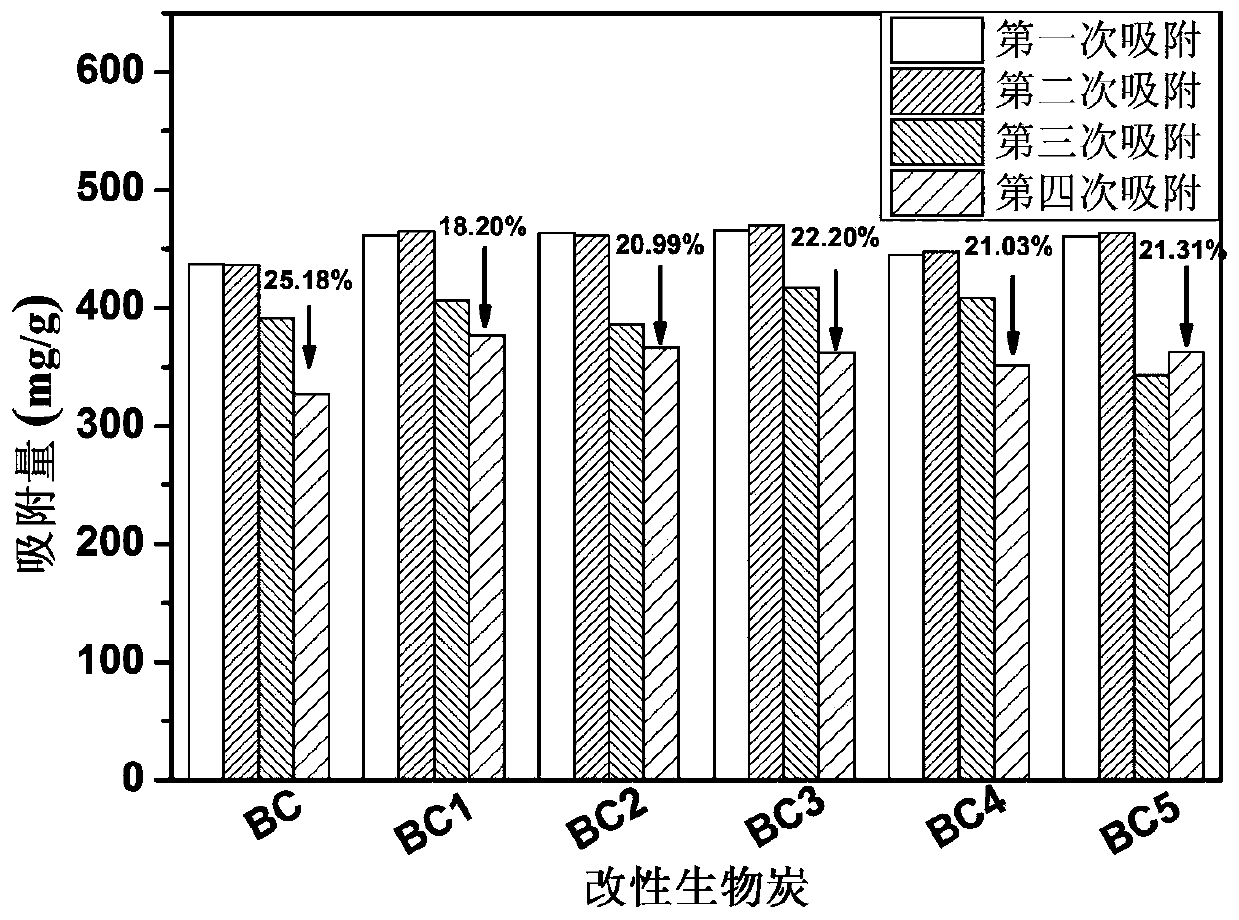

Embodiment 1

[0047] Take 5g of γ-aminopropyltriethoxysilane (KH550) and disperse it in a mixed solution of 10mL ethanol and water (7:3), adjust the pH value to 4 with acetic acid, hydrolyze for 2 hours, and then change the hydrolyzed silane The agent solution and 100g tobacco rod biochar were added to the Sc-CO 2 In the reaction kettle, react at a stirring rate of 180r / min, a reaction temperature of 40°C, and a reaction pressure of 20MPa for 2 hours, then take out the reactants, wash them repeatedly with deionized water, and dry them in a vacuum oven to obtain modified biochar BC1 .

Embodiment 2

[0049] Take 5g of γ-glycidyl etheroxypropyltrimethoxysilane (KH560) and disperse it in a mixed solution of 10mL ethanol and water (7:3), adjust the pH value to 4 with acetic acid, hydrolyze for 2 hours, and then dissolve the hydrolyzed Add silane modifier solution and 100g tobacco rod biochar to Sc-CO 2 In the reaction kettle, react at a stirring rate of 180r / min, a reaction temperature of 40°C, and a reaction pressure of 20MPa for 2 hours, then take out the reactants, wash them repeatedly with deionized water, and dry them in a vacuum oven to obtain modified biochar BC2 .

Embodiment 3

[0051] Take 5g of γ-(methacryloyloxy)propyltrimethoxysilane (KH570) and disperse it in a mixed solution of 10mL ethanol and water (7:3), adjust the pH value to 4 with acetic acid, hydrolyze for 2 hours, and then Add the hydrolyzed silane modifier solution and 100 g tobacco rod biochar to the Sc-CO 2 In the reaction kettle, react at a stirring rate of 180r / min, a reaction temperature of 40°C, and a reaction pressure of 20MPa for 2 hours, then take out the reactants, wash them repeatedly with deionized water, and dry them in a vacuum oven to obtain modified biochar BC3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com