Ultrasonic consolidation forming method of zirconium-steel layered composite material

A layered composite material, ultrasonic technology, applied in the direction of manufacturing tools, non-electric welding equipment, welding/welding/cutting items, etc., can solve the problems of difficult control of the thickness and composition of the bonding layer, difficult operation, complicated process, etc., to achieve increased The effect of combining strength, high process difficulty and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

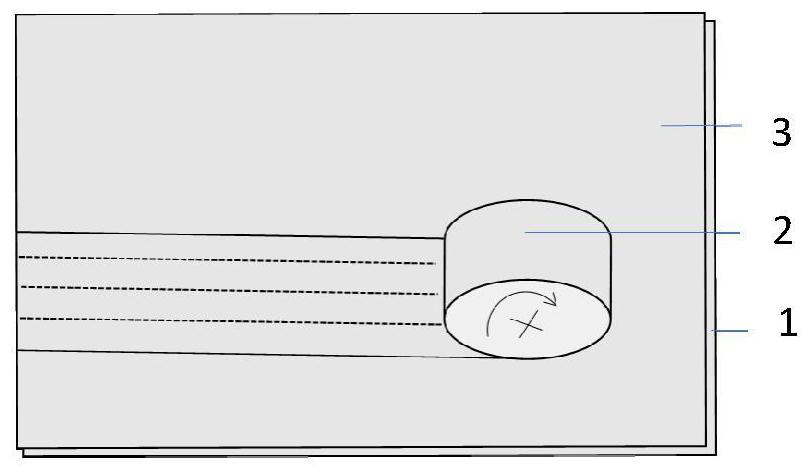

[0023] An ultrasonic consolidation forming method of a zirconium-steel layered composite material, comprising the steps of:

[0024] (1) Carry out surface cleaning treatment to the welded surfaces of the zirconium plate (3), the intermediate layer metal foil and the steel plate (1);

[0025] (2) Stack the metal foil of the middle layer on the welding surface of the steel plate (1), and place the steel plate stacked with the metal foil of the middle layer on the ultrasonic consolidation forming workbench, with the metal foil of the middle layer facing up; preheat Heating up, the preheating temperature is 50-250°C;

[0026] (3) Use ultrasonic consolidation forming equipment (2) to travel straight from one end of the plate to the other end in the same direction for welding, so that the weld seam is even. The consolidation pressure during ultrasonic welding is 1200-2500N, and the ultrasonic amplitude is 10-40μm , the consolidation speed is 20-80mm / s; until the middle layer metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com