Laser machining method and system for a wafer

A laser processing method and laser processing technology, which are applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low wafer slicing yield and efficiency, wafer slicing edge chipping, and damaged grains, etc. , to achieve the effect of improving yield and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

[0035] Such as Figure 1 to Figure 7 As shown, the present invention provides a preferred embodiment of a laser processing method for a wafer.

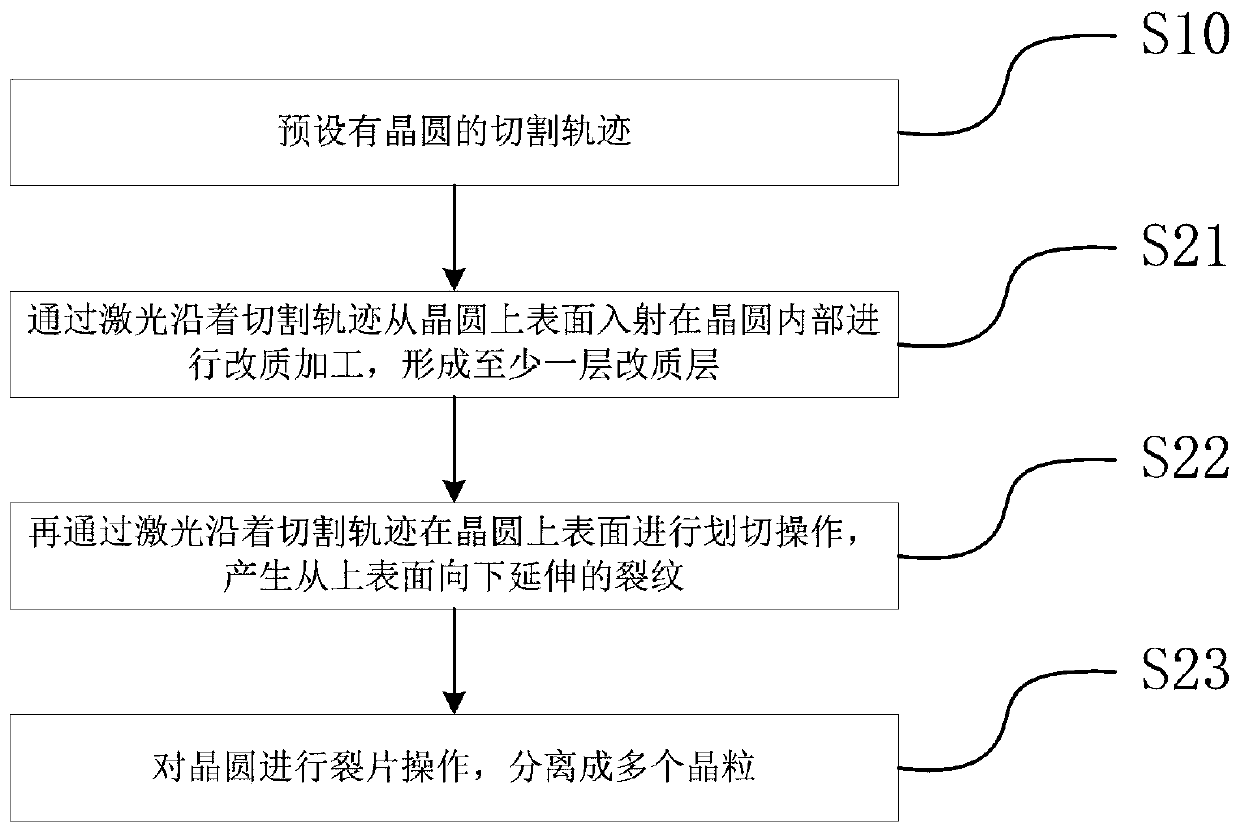

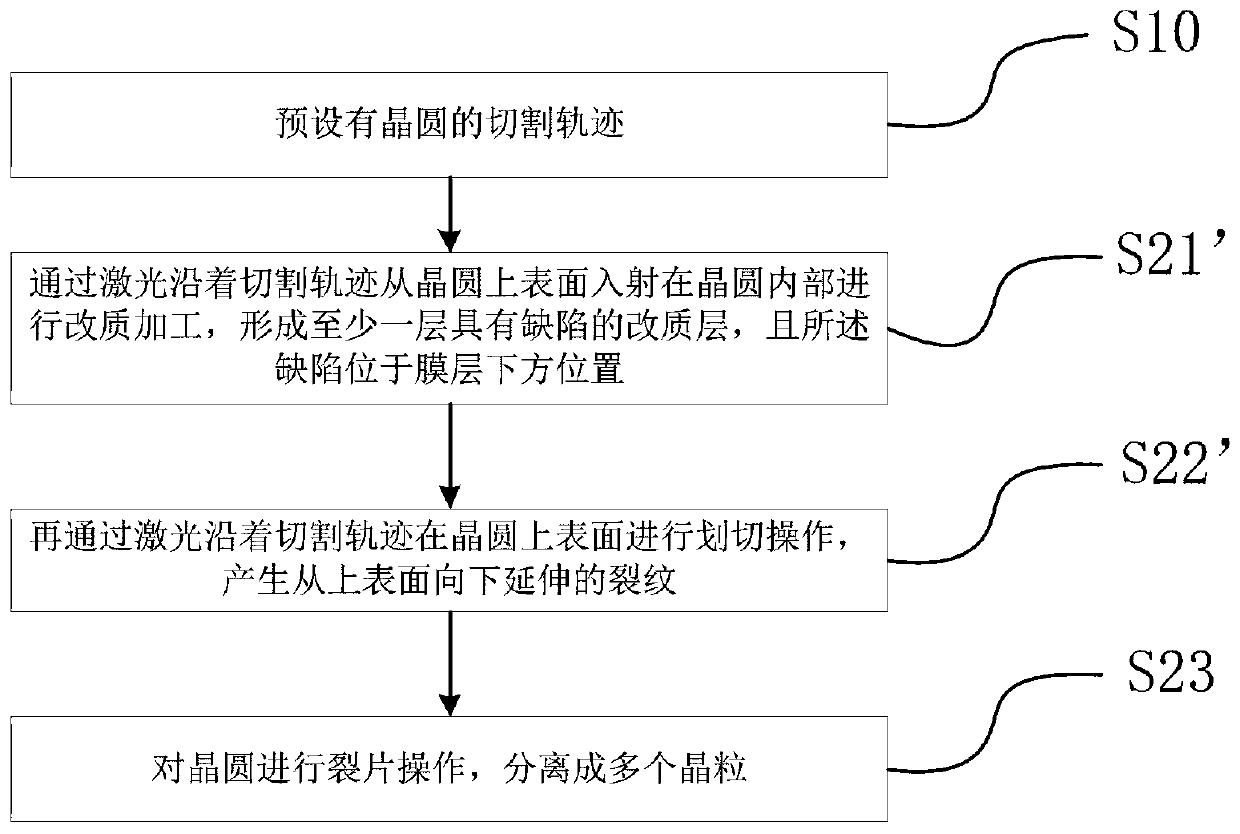

[0036] A kind of laser processing method of wafer 100, described laser processing method comprises steps:

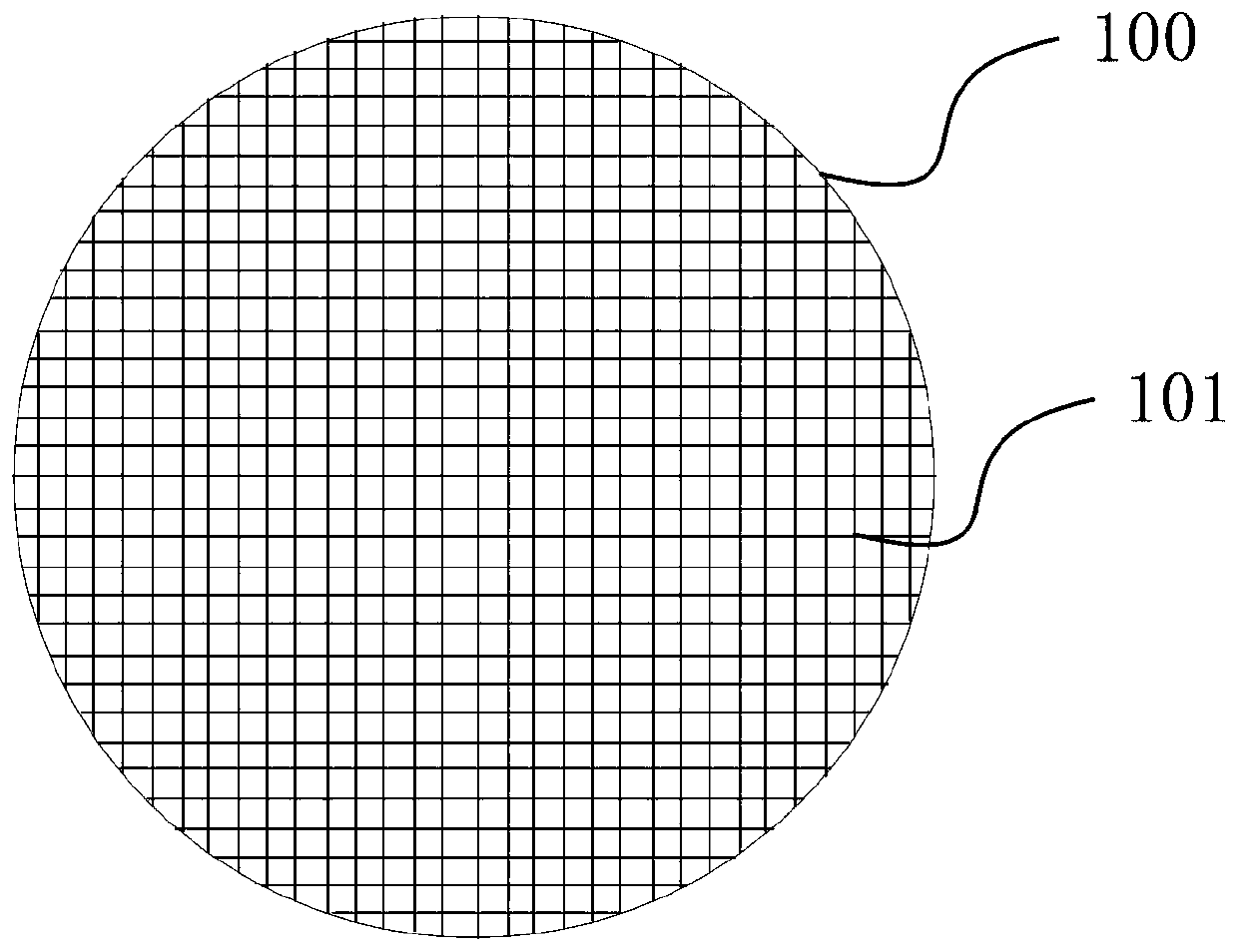

[0037] Step S10, the cutting track 101 of the wafer 100 is preset;

[0038] Step S21, using the laser to incident on the wafer 100 from the upper surface of the wafer along the cutting track 101 to perform modification processing to form at least one modification layer 120;

[0039] Step S22, performing a scribing operation on the upper surface 111 of the wafer 100 along the cutting track 101 with a laser to generate cracks 130 extending downward from the upper surface 111;

[0040] Step S23 , splitting the wafer 100 into multiple crystal grains 200 .

[0041] Specifically, provide a waf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com