Pipecolinic acid preparation process based on reverse dropping

A preparation process, pipecolic acid technology, applied in the field of medicine, can solve the problems of long time, long preparation time, and difficult difficulty reduction, and achieve the effect of improving preparation efficiency, reducing duration, and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

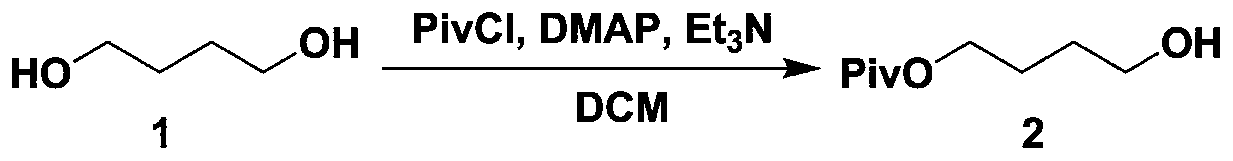

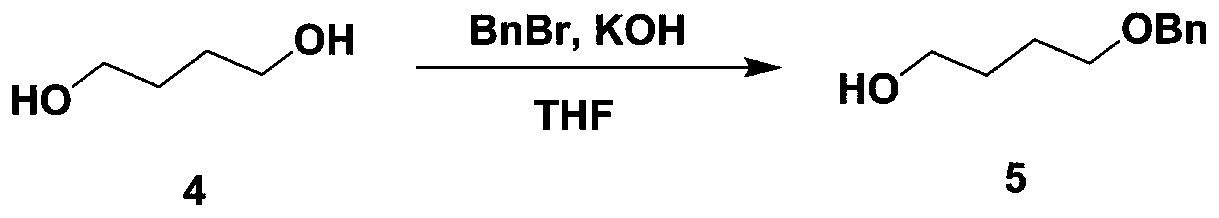

[0062] see Figure 1-15 , a pipecolic acid preparation process based on reverse dropwise addition, comprising the following steps:

[0063] S1, 6Kg raw material 1, 4.7Kg triethylamine, 50g DMAP were dissolved in 36Kg dichloromethane, cooled to 0-20°C, 3.2Kg pivaloyl chloride was added dropwise, the temperature was controlled at 0-5°C, and the addition was completed in 10 hours, 0- Stir and react at 5°C for 1 hour, GC detection of pivaloyl chloride ≤ 1%; directly add 40Kg of water to quench, stir and separate the liquid, then wash with 30Kg of 5% citric acid aqueous solution to weak acidity, dry the organic phase with anhydrous sodium sulfate, and filter , the solution is waiting for the next step;

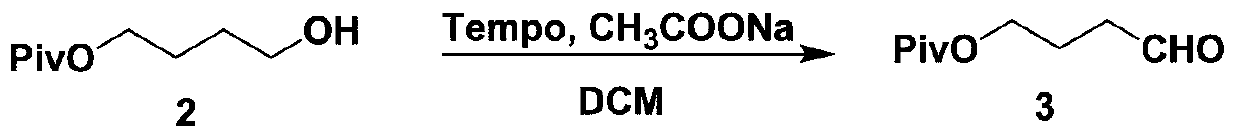

[0064] S2. Add 2, sodium acetate, Tempo, anhydrous sodium sulfate and DCM to a 50L reactor, and react at a temperature of 10-20°C for 5 hours; GC detection shows that the content of 2 is less than or equal to 5%, and the material is discharged and filtered, 10Kg 5% sulfur Wash wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com