Method for acquiring lignin with high phenolic hydroxyl group content from residues after hemicelluloses degradation conversion

A technology of hemicellulose and high phenolic hydroxyl group is applied in the field of obtaining lignin with high phenolic hydroxyl group content, which can solve the problems of insufficient utilization of lignin resources, increase of process complexity and cost, weak selectivity of depolymerization and dissolution, and the like, Achieve the effect of easy recovery and recycling, improving quality and added value, and high extraction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

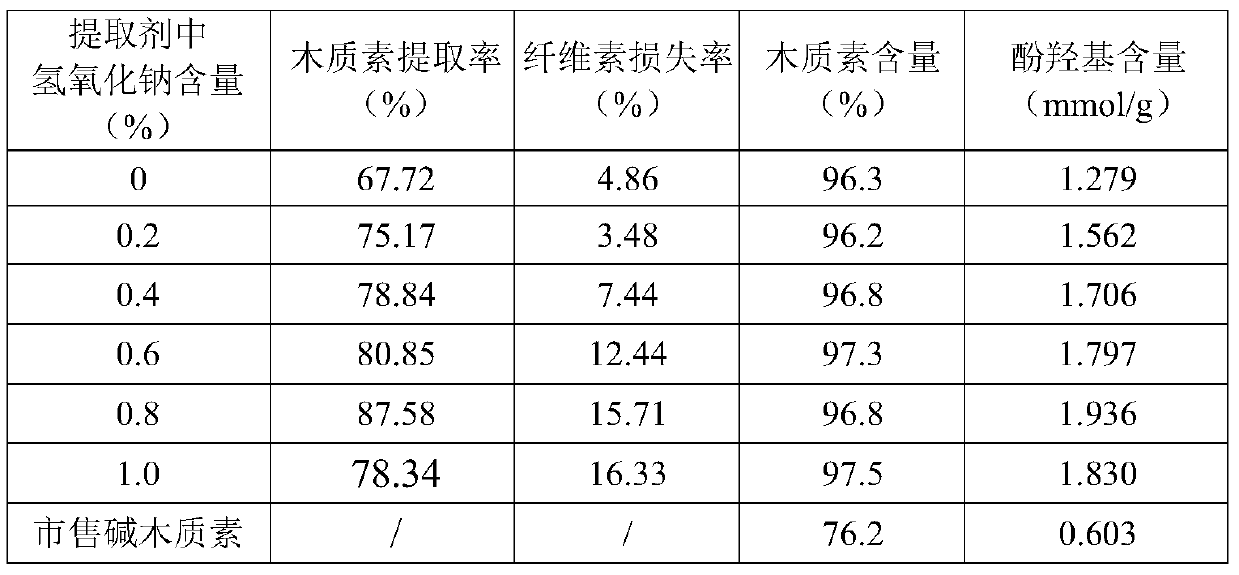

[0026] The corn stalk residue after extracting xylooligosaccharide is used as raw material, the content of tetrahydrofuran in the extractant is 50wt%, the content of sodium hydroxide is 0-1wt%, and the rest is water. According to the solid-liquid mass volume ratio (kg / L) of 1:15, the two were mixed in a high-pressure reactor, the temperature was raised to 170 ° C, and the extraction was carried out for 150 minutes. After the extraction is completed, filter separately, collect the filtrate, and distill to recover the solvent. The remaining water phase is adjusted to pH 2.0 with sulfuric acid, and water is added to obtain lignin precipitation. Ready to serve after drying. The extraction rate of lignin, lignin content (dry dry) and phenolic hydroxyl content (dry dry) in the product were compared, and commercially available alkali lignin was used as a control, as shown in Table 1.

[0027] Table 1

[0028]

[0029] From the data in Table 1, it can be seen that after adding a ...

Embodiment 2

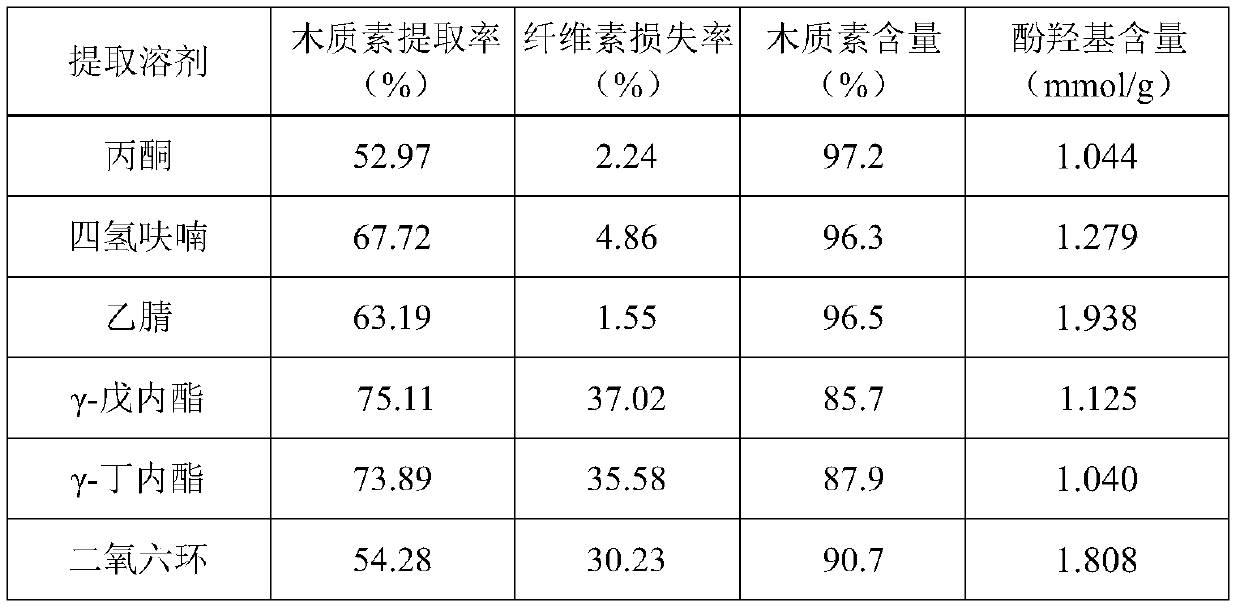

[0034] The wheat stalk residue after extracting xylooligosaccharide is used as raw material, the content of tetrahydrofuran in the extractant is 50wt%, the content of sodium hydroxide is 0.6wt%, and the rest is water. According to the solid-liquid mass volume ratio (kg / L) of 1:12, the two were mixed in a high-pressure reactor, heated to 160°C, and kept for extraction for 120 minutes. After the extraction, filter, collect the filtrate, distill and recover the solvent, adjust the remaining water phase to pH 3.0 with sulfuric acid, and add water to obtain lignin precipitation. Ready to serve after drying. The extraction rate of lignin, lignin content (dry dry) and phenolic hydroxyl content (dry dry) in the product were compared, and commercially available alkali lignin was used as a control, as shown in Table 3.

[0035] table 3

[0036]

[0037] It can be seen from the data in Table 3 that the lignin content in the product is ≥97% and the content of phenolic hydroxyl groups...

Embodiment 3

[0039]The bagasse residue after extracting xylooligosaccharide is used as raw material, the content of tetrahydrofuran in the extractant is 60wt%, the content of potassium hydroxide is 0.8wt%, and the rest is water. According to the solid-liquid mass volume ratio (kg / L) of 1:10, the two were mixed in a high-pressure reactor, heated to 160°C, and kept for extraction for 135 minutes. After the extraction is completed, filter, collect the filtrate, and distill to recover the solvent. The remaining water phase is adjusted to pH 2.5 with sulfuric acid, and water is added to obtain lignin precipitation. The product is filtered, washed with 3 times the volume of water, and dried at 80-100°C Get it later. The extraction rate of lignin, lignin content (dry dry) and phenolic hydroxyl content (dry dry) in the product were compared, and commercially available alkali lignin was used as a control, see Table 4.

[0040] Table 4

[0041]

[0042] It can be seen from Table 4 that the meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com