Mulberry wine and preparation method thereof

A technology of mulberry wine and distiller's yeast, which is applied in the field of wine-making technology, can solve the problems that the high-quality requirements of drinking wine cannot be met, the fragrance of mulberry wine is weak, and the preparation process is complicated, and the cost is low, suitable for popularization and application, and the preparation process is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

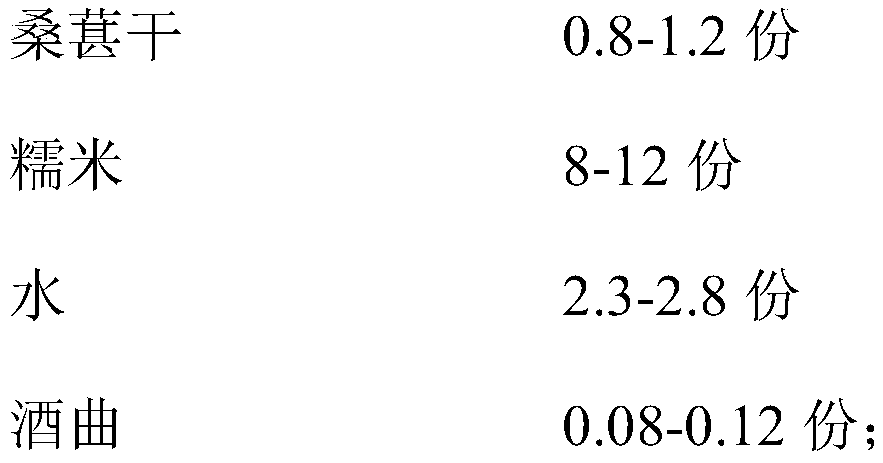

[0030] The mulberry wine of the present embodiment, in parts by mass, the mulberry wine includes the following raw materials:

[0031]

[0032] Wherein, the distiller's yeast includes the following components: cereal flour, wheat bran, dragonfly grass and chrysanthemum brain.

Embodiment 2

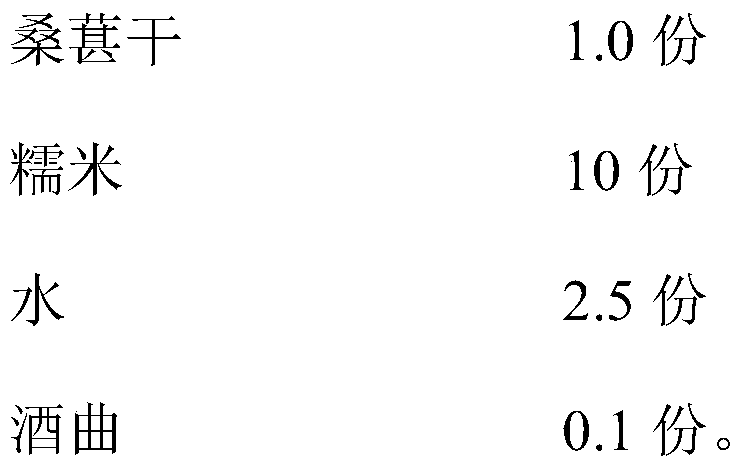

[0034] The mulberry wine of the present embodiment, in parts by mass, the mulberry wine includes the following raw materials:

[0035]

[0036] Wherein, the distiller's yeast includes the following components: cereal flour, wheat bran, dragonfly grass and chrysanthemum brain.

Embodiment 3

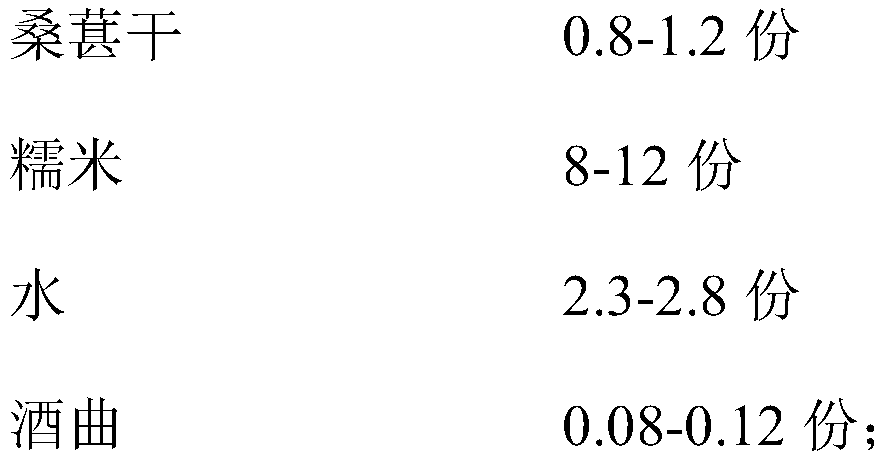

[0038] The mulberry wine of the present embodiment, in parts by mass, the mulberry wine includes the following raw materials:

[0039]

[0040] Wherein, the distiller's yeast includes the following components: cereal flour, wheat bran, dragonfly grass and chrysanthemum brain.

[0041] The alcohol content scope of the mulberry wine of embodiment one to embodiment three is between 15 °-20 °.

[0042] Embodiment three is the best embodiment, and the alcohol content of its mulberry wine is about 15 °, and mouthfeel and fragrance are the best.

[0043] The dried mulberries in the three embodiments are all selected from fresh mulberries, washed with water and put into a drying machine to make the dried mulberries. Dried mulberry has low water content, which is convenient for preservation and can maintain the fresh taste of mulberry.

[0044] The preparation method of distiller's yeast described in embodiment one to embodiment three is:

[0045] Put the dragonfly grass into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com