Coal underground gasifier air pouring and discharging drilling channel heat insulating hermetic stemming method

A technology of underground gasification and gasification furnace, which is applied in coal gasification, underground mining, earthwork drilling and mining, etc. It can solve the problems of not considering the influence of gasification furnace, difficult to isolate and seal, and no heat insulation and sealing scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in combination with specific embodiments.

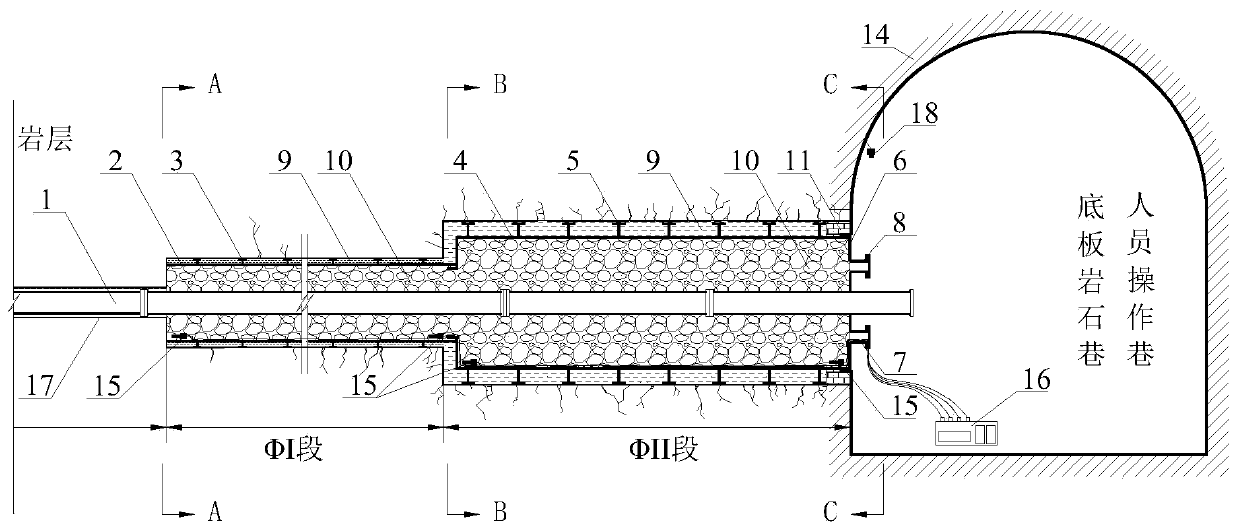

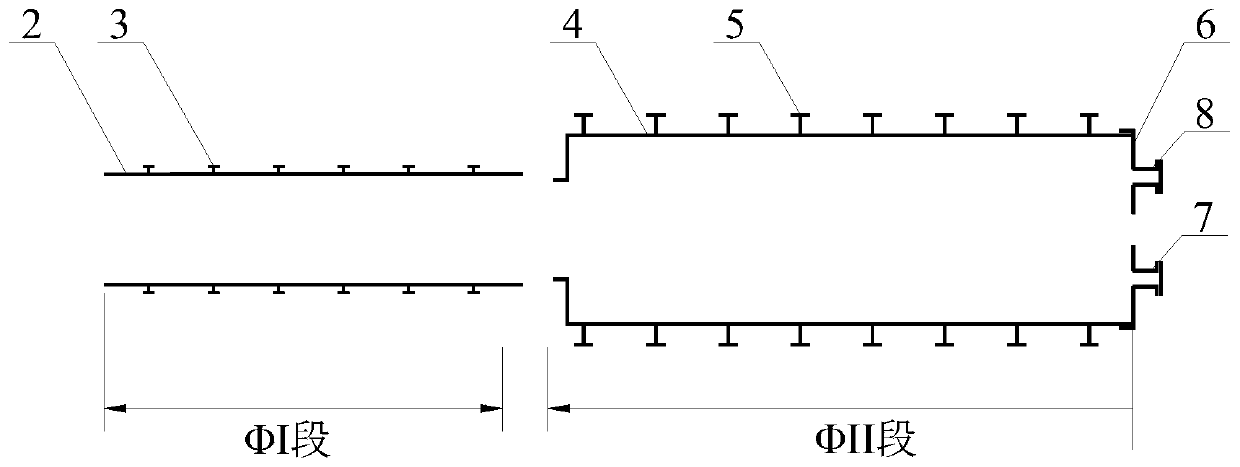

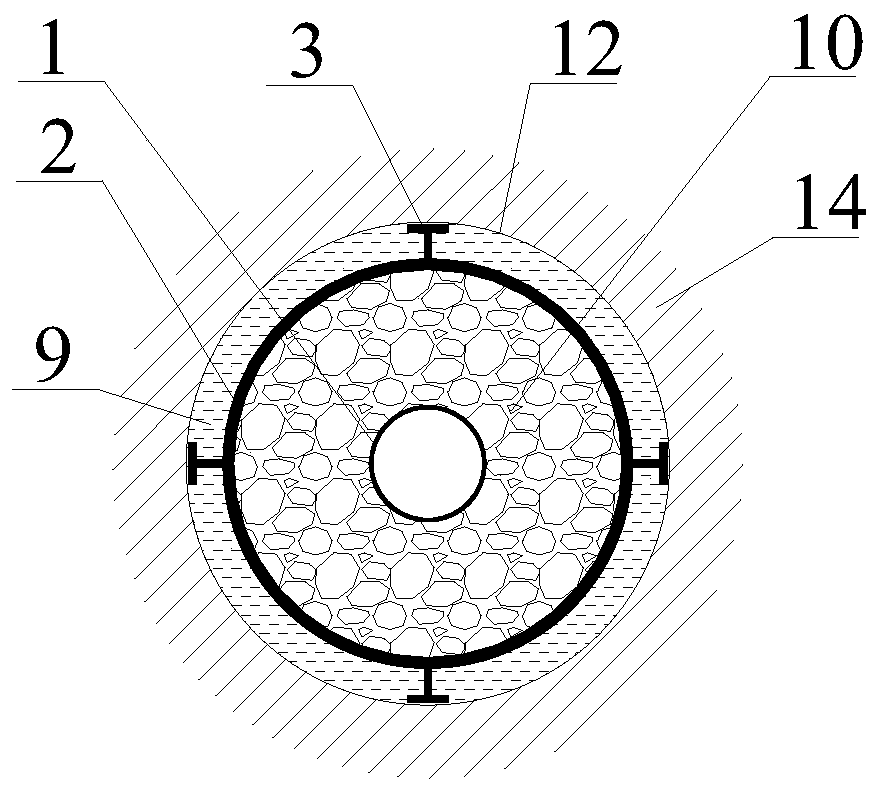

[0021] The present invention as Figure 1 to Figure 5 As shown, the gas injection drilling channel or exhaust drilling channel 17 is set near the sealed drilling channel of different diameters at one end of the floor rock roadway ΦI section drilling channel 12 and the ΦII section drilling channel 13, and the separation casing 1 of different diameters 2 and separation sleeve II 4, high-strength high-temperature-resistant material 9, high-temperature-resistant cement 10, and temperature monitoring system 16. The gas injection drilling channel or the exhaust drilling channel 17 is constructed from the coal underground gasifier bottom plate rock roadway, and the gas injection drilling channel and the exhaust drilling channel reaming channel of the coal underground gasification furnace are divided into two parts. It is ΦI section and ΦII section, with different inner diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com