Steel weight-reduction type double-web pressing slide wheel and manufacturing method thereof

A technology of webs and pulleys, applied in the direction of belts/chains/gears, portable lifting devices, components with teeth, etc., can solve the problems of poor precision of rolling pulley rims, deterioration of mechanical properties of steel parts, high pulley scrap rate, etc. , to achieve the effect of long wear-resistant service life, reasonable structural design, good strength and rigidity of the wheel groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

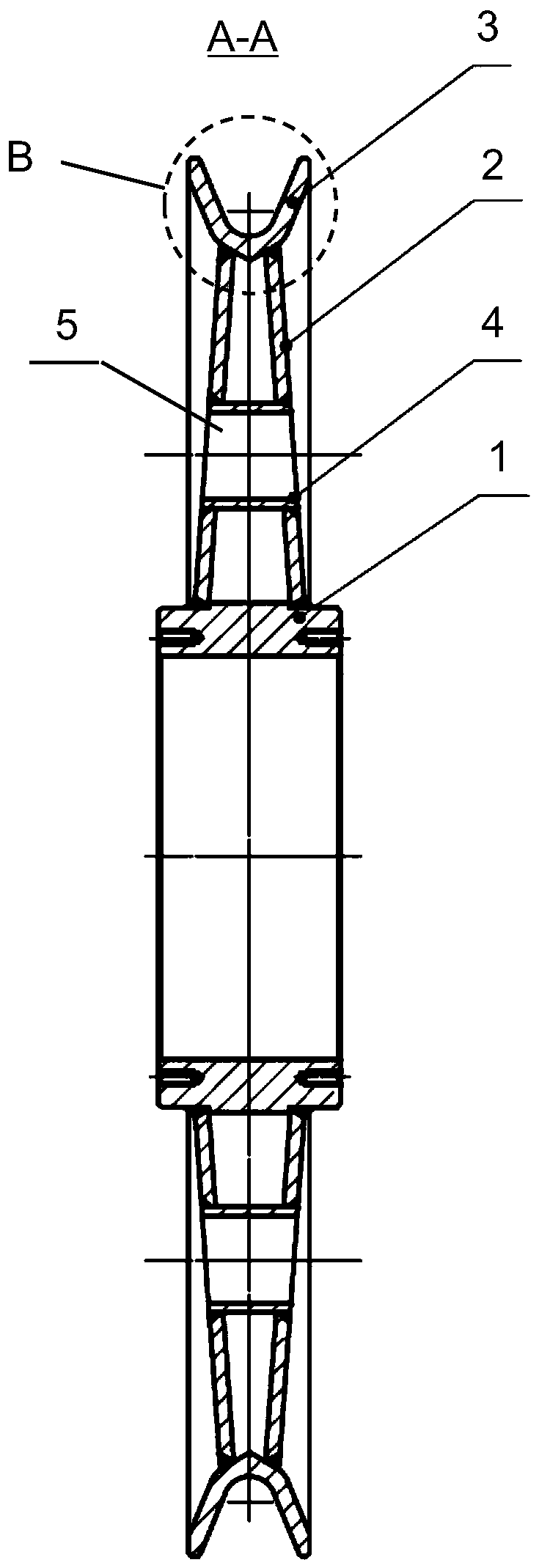

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

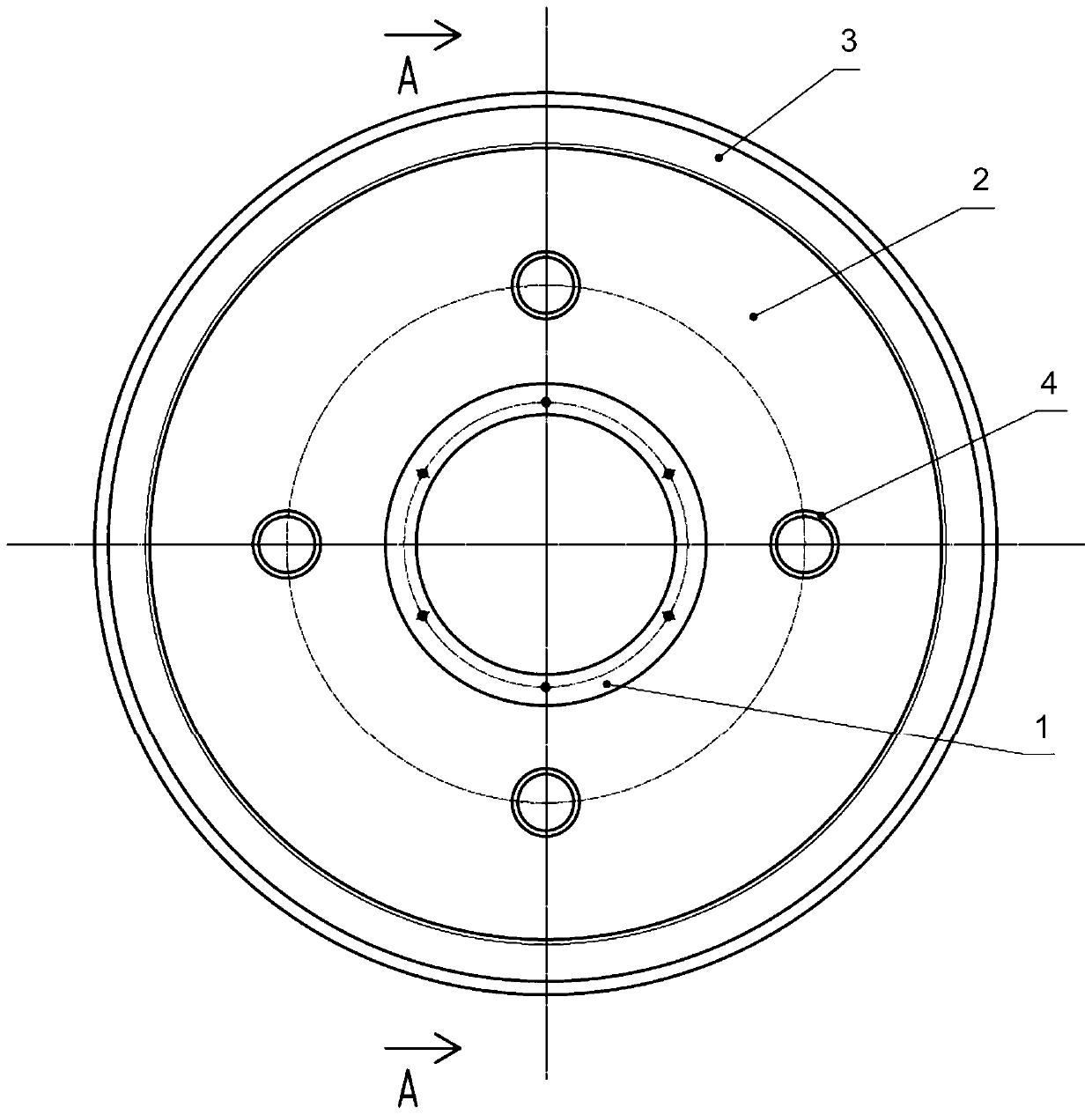

[0037] Please combine Figure 1 to Figure 3 As shown, a kind of steel weight reduction double-panel plate pressing pulley provided by the present invention, said pulley comprises wheel hub 1, the web plate 2 that is connected on the wheel hub 1, and the rim 3 that is connected on the web plate 2, above-mentioned is The prior art part will not be repeated here. The difference from the prior art is:

[0038] Preferably, the hub 1 is configured as a tubular structure.

[0039] Preferably, the web 2 has two pieces, both of which are in the shape of a hollow ring, and are arranged as a figure-eight supporting frame structure welded on the hub 1 . The big mouth end of this figure-eight supporting frame structure is welded on the wheel hub 1.

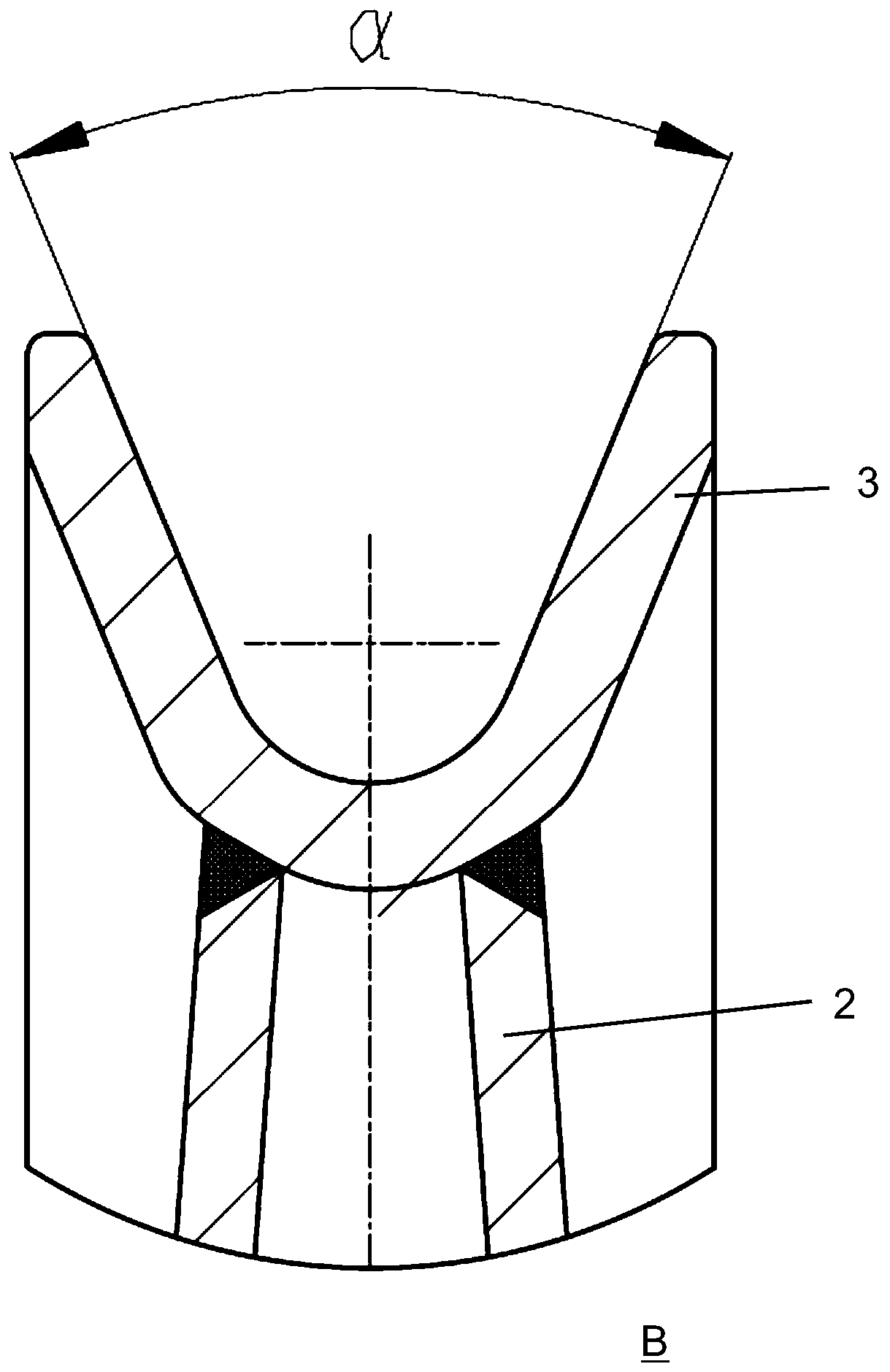

[0040] Preferably, the rim 3 is an annular structure with a U-shaped cross-section, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com