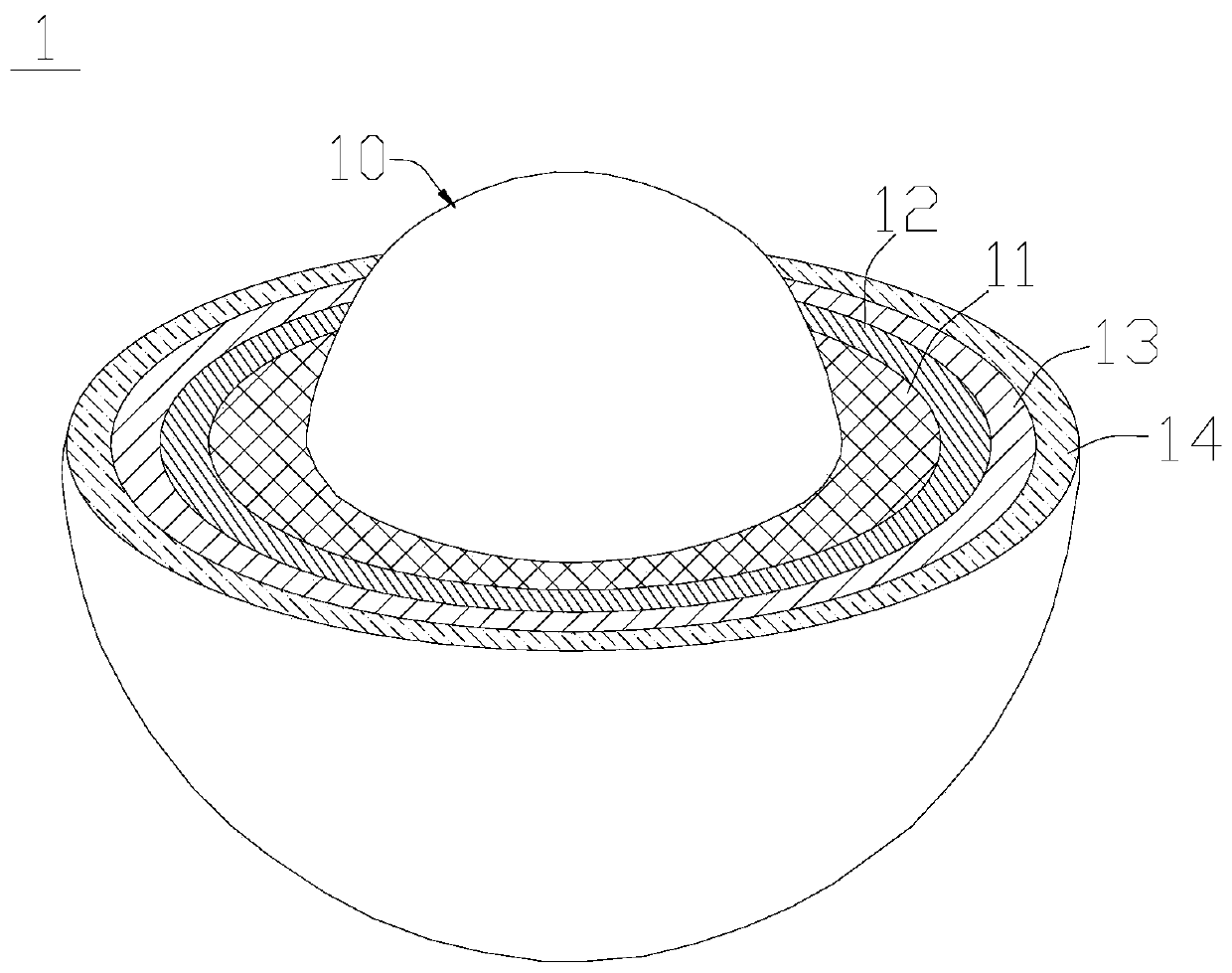

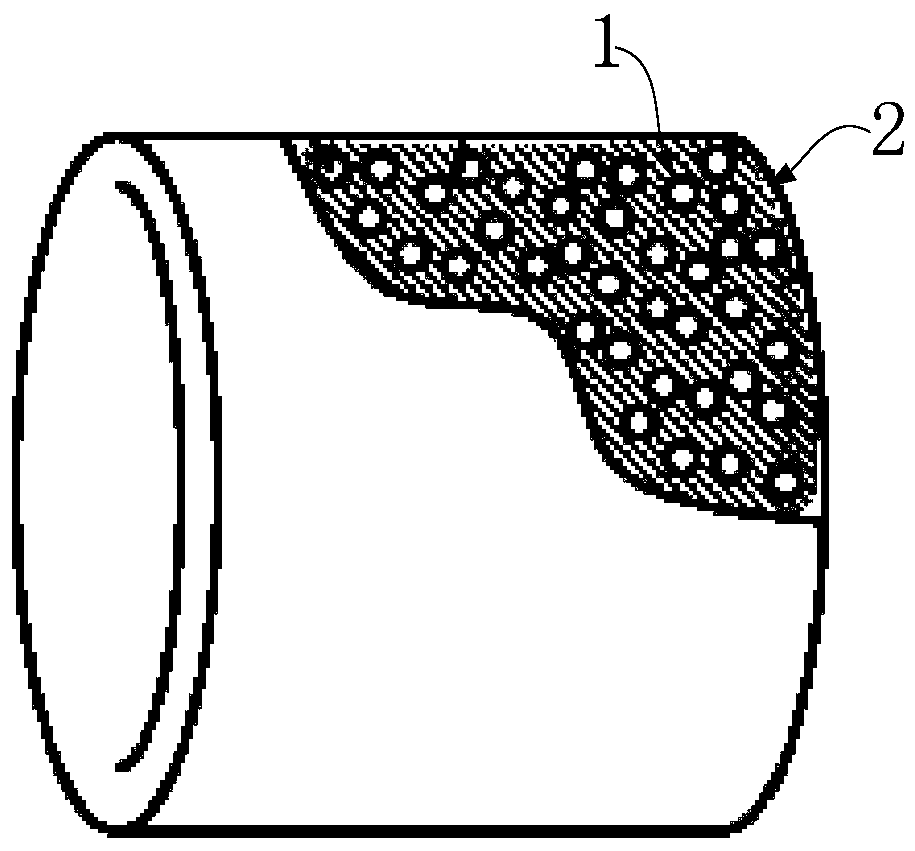

Manufacturing method of high-uranium-density coated fuel particles, inert matrix dispersion fuel pellet, integrated fuel rod and manufacturing method thereof

A technology for coating fuel particles and manufacturing methods, which is applied in the direction of manufacturing reactors, reactor fuel materials, and climate sustainability. It can solve problems such as high cost, waste liquid pollution, and inability to use chemical methods, so as to reduce preparation costs and improve economic efficiency. performance, improving the effect of uranium loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

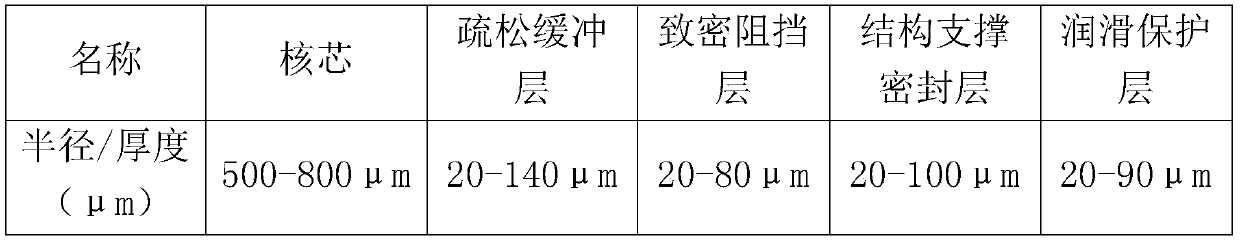

Embodiment 1

[0104] Obtain high-purity U through powder separation 3 Si 2 powder.

[0105] Weigh a certain amount of U 3 Si 2 The powder is mixed with 2-5 wt.% binder to form a viscous mass. Extrude the viscous material from the pores with a fine hole extrusion die to form a short column with a length of 700±50nm. Use a sintering furnace to pre-fire the short cylinder. The pre-fire temperature is 400°C-600°C. After 3-5 hours of heat preservation, the temperature is lowered with the furnace. The size shrinkage of the pellets was not obvious. Place the pre-burned short cylinder in a ball mill, turn the lower turntable, and grind at a speed of 50r / min for 10-12 hours to form pellets. The pellets after grinding are taken out for cleaning and screening, and the pellets with a size of 600±50nm are screened out. Sieve out the qualified pellets for sintering, use the atmosphere sintering furnace, pass H 2 atmosphere, the sintering temperature is 1300°C-1500°C, the diameter of the sintered ...

Embodiment 2

[0110] Obtain high-purity U through powder separation 3 Si 2 powder.

[0111] Weigh a certain amount of U 3 Si 2 The powder is mixed with 2-5 wt.% binder to form a viscous mass. Extrude the viscous material from the pores with a pore extrusion die to form short columns with a length of 600-700nm. Use a sintering furnace to pre-fire the short cylinder. The pre-fire temperature is 500±50°C. After holding for 2-5 hours, the temperature is lowered with the furnace. The density of the pre-fired short cylinder is 80% T.D. Ball size shrinkage was not apparent. Place the pre-fired short cylinder in a ball mill, turn the lower turntable, and grind at a speed of 50±10r / min for 8-16 hours to form small balls. The pellets after grinding are taken out for cleaning and screening, and the pellets with a size of 600±50nm are screened out. Sieve out the qualified pellets for sintering, use the atmosphere sintering furnace, pass H 2 atmosphere, the sintering temperature is 1300°C-1500°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com