High-reliability anti-shock small-sized YAG laser

A YAG laser, reliability technology, applied in the direction of lasers, laser parts, laser parts, etc., can solve the problem of low reliability and achieve the effect of high reliability, small deformation, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the scope of the present invention is not limited in any way.

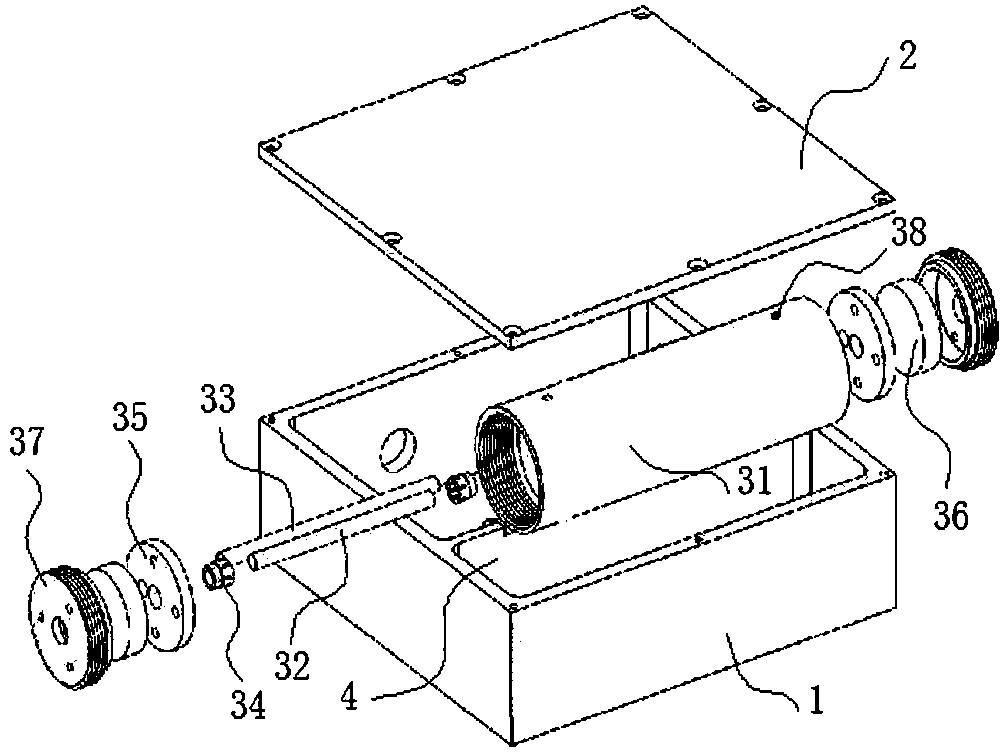

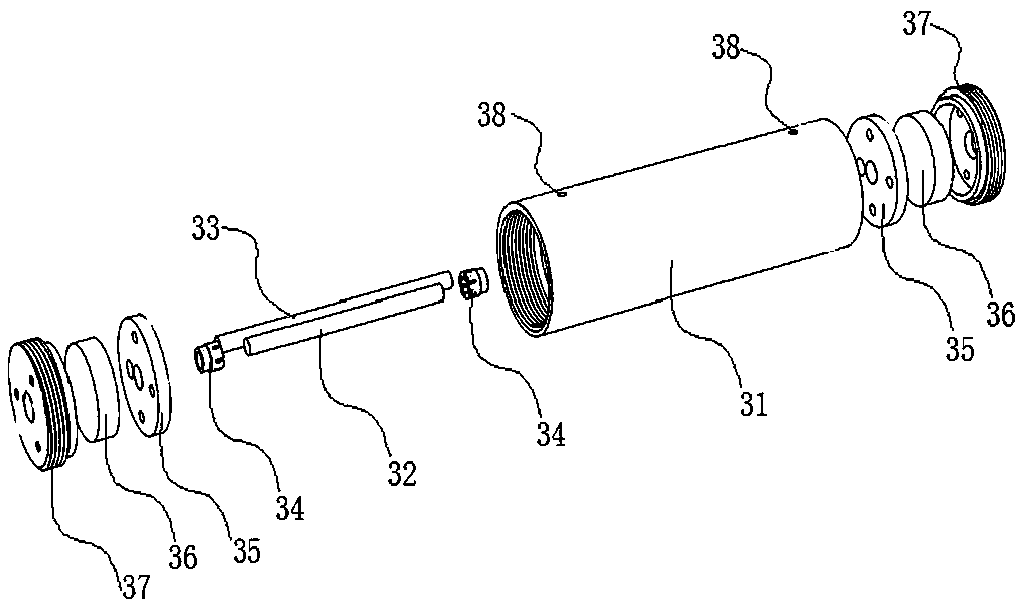

[0021] A high-reliability shock-resistant small YAG laser, including a casing 1, an upper cover 2, and a laser cavity. The laser cavity is a cylinder and is located in the casing 1. The casing 1 also includes a control circuit. The laser cavity and the control circuit are separated by an interlayer 4. Open; the laser cavity includes a cylinder body 31, a laser crystal rod 32, a xenon lamp 33, a rod cover 34, a rod holder 35, a cavity mirror 36, an outer mirror frame 37 and an outlet hole 38; connection; the cylinder body 31 is a through-hole cylinder, and the inner diameter of the middle of the cylinder body 31 is smaller than the inner diameter of both ends, forming two annular bosses; a wire outlet hole 38 is provided on the cylindrical surface at both ends of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com