Preparation method of enhanced cooling carbon based composite film

A production method and composite film technology, which are applied in cooling/ventilation/heating transformation, modification by conduction heat transfer, etc., can solve the problems of heat source dissipation, poor surface thermal conductivity, etc., and achieve better heat dissipation performance, easy combination, Simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

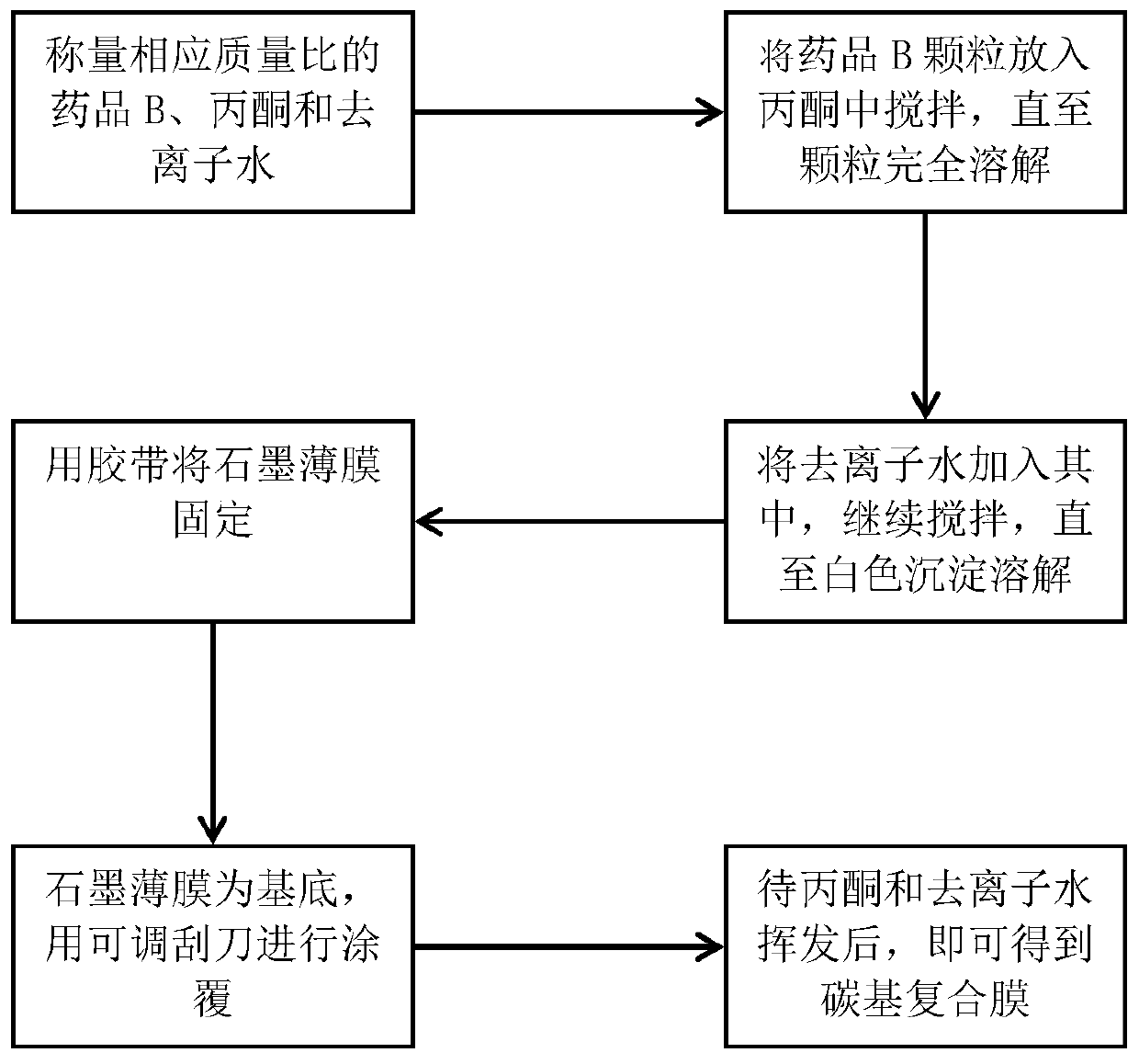

[0027] 1. The mass ratio of the three is required to be: drug B: acetone: deionized water = 1:8:1. So weigh 6.25 grams of drug B, 50 grams of acetone and 6.25 grams of deionized water.

[0028] 2. Pour the weighed drug B granules into a beaker filled with acetone, set the water bath temperature of the collector type constant temperature heating magnetic stirrer to 40°C, and stir for 20 minutes until the granules are completely dissolved.

[0029] 3. Add the weighed deionized water into the solution in step 2, keep stirring for 20 minutes at the same water bath temperature, until the white precipitate is completely dissolved to obtain the precursor solution.

[0030] 4. Fix the 25um thick graphite film on the plate with adhesive tape. The purpose is to prevent the graphite film from being brought up when the solution evaporates, causing wrinkles. Use an adjustable scraper for coating, and control the height of the adjustable scraper to 1500um . Then let it air-dry naturally, ...

Embodiment 2

[0032] 1. The mass ratio of the three is required to be: drug B: acetone: deionized water = 1:8:1. So weigh 6.25 grams of drug B, 50 grams of acetone and 6.25 grams of deionized water.

[0033] 2. Pour the weighed granules of drug B into a beaker filled with acetone, set the water bath temperature of the collector type constant temperature heating magnetic stirrer to 40°C, and stir for 20 minutes until the granules are completely dissolved.

[0034] 3. Add the weighed deionized water into the solution in step 2, keep stirring for 20 minutes at the same water bath temperature, until the white precipitate is completely dissolved to obtain the precursor solution.

[0035] 4. Fix the 25um thick graphite film on the plate with adhesive tape. The purpose is to prevent the graphite film from being brought up when the solution evaporates, causing wrinkles. Use an adjustable scraper for coating, and control the height of the adjustable scraper to 2000um . Then let it air-dry naturall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com