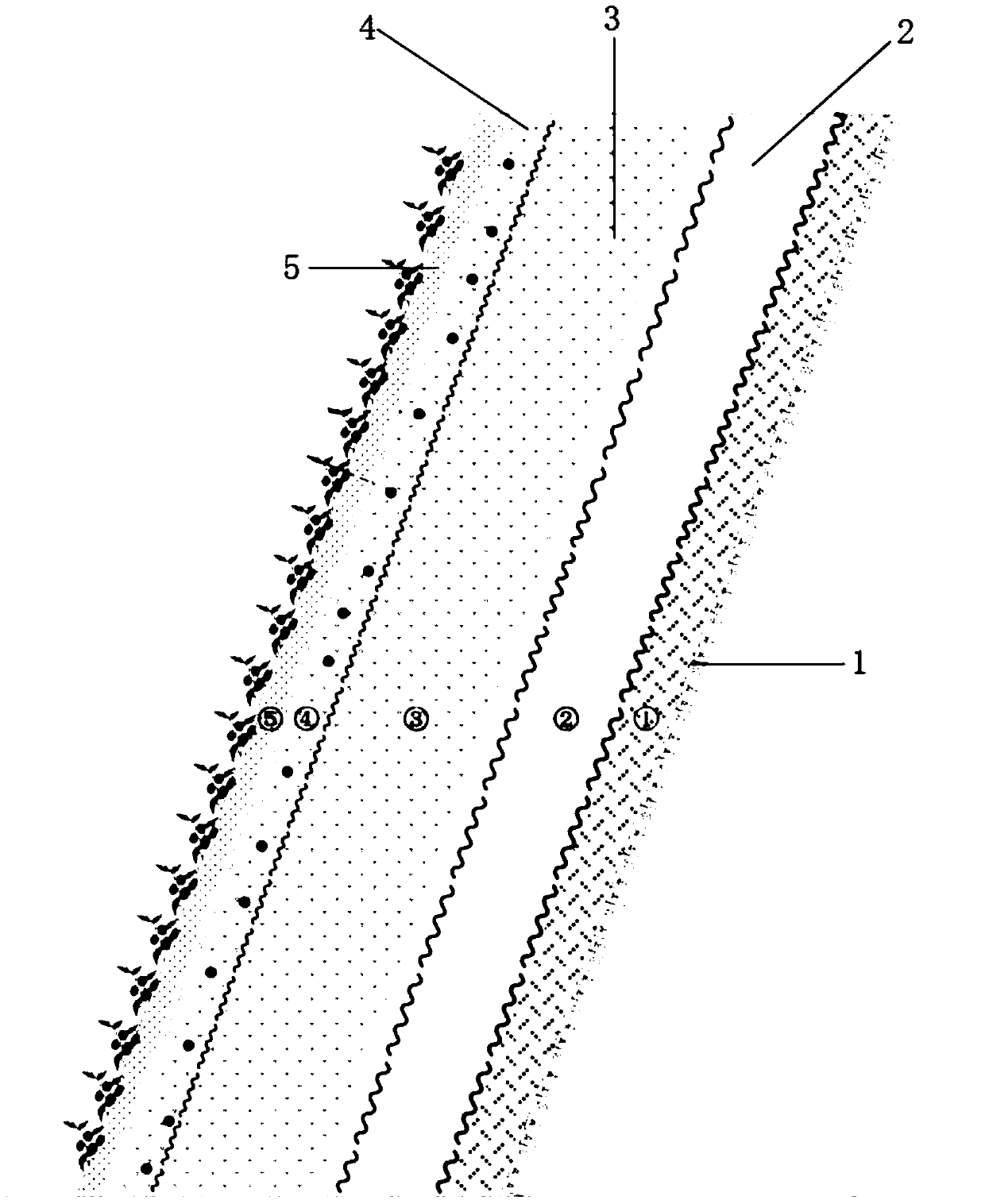

High-steep bare rock slope surface vegetation greening system and construction method thereof

A construction method and bare rock technology, applied in botanical equipment and methods, planting substrates, plant cultivation, etc., can solve the problems of high maintenance cost, secondary soil pollution, high cost, etc., and achieve improved physical and mechanical properties and service time , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0122] Take the treatment of an extremely steep rock slope in an open-pit quarry in Shandong Province as an example to illustrate it.

[0123] Take an open-pit granite quarry in Shandong as an example. The quarry is an old quarry that has been mined for more than 30 years. The high and steep rock slope is a massive structure slope with a slope height or relative height difference of 62.4 meters and a slope of 42-75° , belonging to high and steep rock slopes. The rock slope is 66 meters long, and the high and steep bare rock area is about 2130m 2 . The bare rock slope is relatively flat, without obvious faults and fissures. It is an impermeable rock group. There are no weak zones in the rock mass. There are only 5 vertical joints with a joint width of 1-2mm and a joint fissure rate of 0.19%. There is no weathered layer, and the bare rock slope is very solid. According to the requirements of the competent department of mineral resources, the mine restoration and management of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com