Pipeline shot blasting derusting machine

A derusting machine and pipeline technology, applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., can solve the problems of difficult to meet the requirements of noise control in environmental protection workshops, unfavorable production state control, and high working noise. Achieve the effect of reducing the difficulty of repair and maintenance, facilitating on-site installation, and meeting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

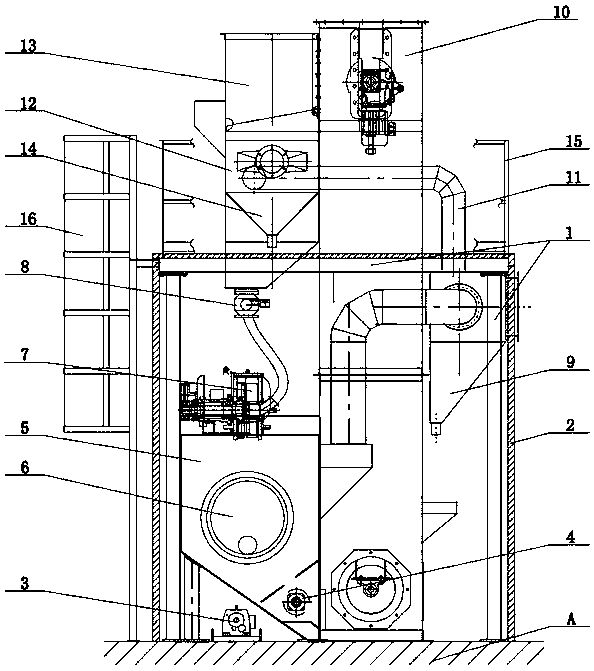

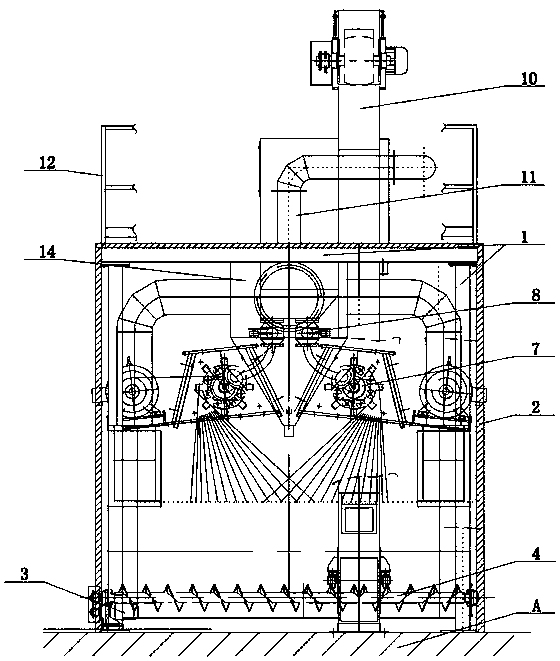

[0016] See Figure 1-Figure 2 As shown, the technical solution adopted in this specific embodiment is: it includes a steel structure platform 1, a noise reduction plate 2, a motor 3, a horizontal screw conveyor 4, a shot blasting chamber 5, an inlet and outlet pipe sealing device 6, a centrifugal shot blasting device 7. Pellet controller 8, settling box 9, bucket elevator 10, vacuum duct 11, storage box 12, pill slag separator 13, funnel 14, steel structure platform 1 with noise reduction board outside 2. There is a motor 3 on the left side of the bottom of the steel structure platform 1. The motor is set on the ground A, the output end of the motor 3 is connected with the horizontal screw conveyor 4, and the upper end of the horizontal screw conveyor 4 is connected with the shot blasting chamber 5. , The front end of the shot blasting chamber 5 is provided with an inlet and outlet pipe sealing device 6, and the upper end of the shot blasting chamber 5 is provided with a centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com