Preparation method of lignan in albizia bark

A technology of Albizia Julibrissin and lignans, which is applied to the preparation of sugar derivatives, chemical instruments and methods, organic chemistry, etc., can solve the problems of serious pollution in the operation process, large amount of solvent usage, and low yield, and achieve simple process, The effect of improving product purity and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

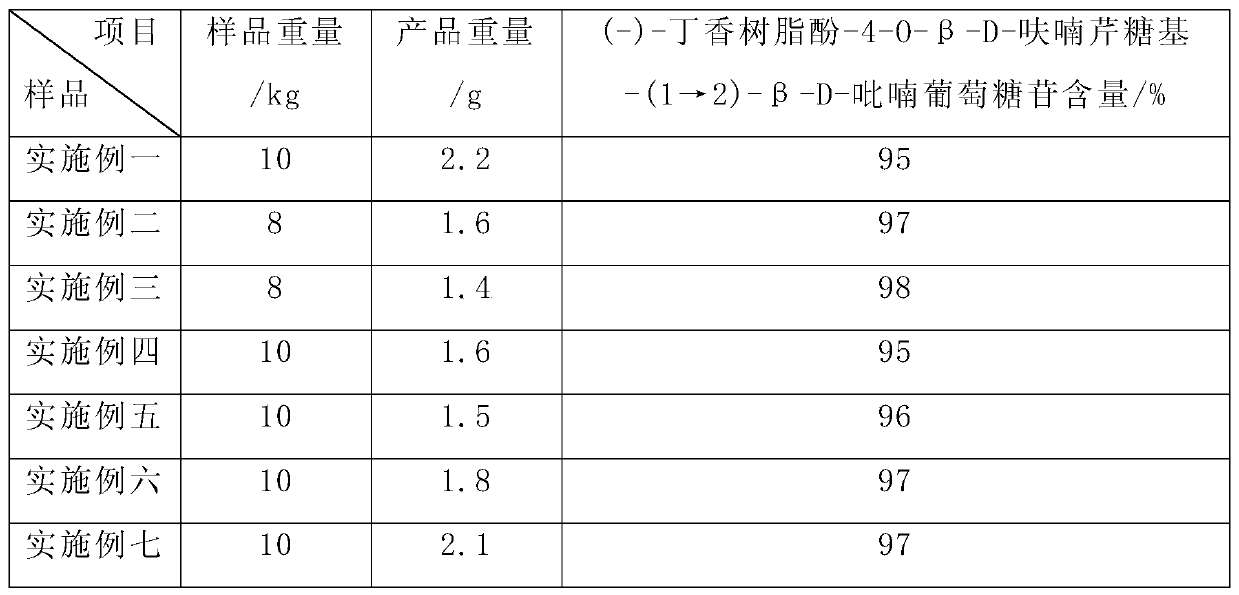

Embodiment 1

[0030] Embodiment one: the preparation of a kind of lignan in Albizia julibrissin bark:

[0031] S1: Take 10 kg of Albizia Julibrissin coarse powder, add 60 kg of water, conduct heating and reflux extraction, repeat heating and reflux extraction twice, each time for 1.5 hours, combine the extracts, and filter.

[0032] S2: The filtrate is added to the pretreated HPD-300 macroporous adsorption resin column, the flow rate is controlled at 1BV / h, the effluent is discarded, and 5% ethanol 15000mL is used as the impurity removal agent for impurity removal, and the flow rate is 1BV / h , the eluted impurity removal solution was discarded, and then 20000ml of 50% ethanol solution was used as the eluent for elution, the flow rate was 1BV / h, the collected eluate was concentrated under reduced pressure to syrup, the residue was added with diatomaceous earth, and pulverized into fine powder:.

[0033] S3: Extract 4 times with methanol and dichloromethane mixed solution with a volume ratio...

Embodiment 2

[0035] Embodiment two: the preparation of a kind of lignan in Albizia Julibrissin bark:

[0036] S1: Take 8 kg of Albizia Julibrissin coarse powder, add 120 kg of water, conduct heating and reflux extraction, repeat heating and reflux extraction for 4 times, each time for 1 hour, combine the extracts, and filter.

[0037] S2: The filtrate is added to the pretreated HPD-100 macroporous adsorption resin column, the flow rate is controlled at 2BV / h, the effluent is discarded, and 8000mL of 10% ethanol is used as the impurity removal agent for impurity removal, and the flow rate is 2BV / h , the eluted impurity-removing liquid is discarded, and then eluted with 40% ethanol solution 20000ml as the eluent, the flow rate is 1BV / h, the collected eluate is concentrated under reduced pressure to syrup, the residue is added with diatomaceous earth, and pulverized into fine powder:.

[0038] S3: Extract 5 times with a mixture of methanol and dichloromethane at a volume ratio of 1:7, filter...

Embodiment 3

[0040] Embodiment three: the preparation of a kind of lignan in Albizia julibrissin bark:

[0041] S1: Take 8 kg of Albizia Julibrissin coarse powder, add 80 kg of water, conduct heating and reflux extraction, repeat heating and reflux extraction for 3 times, each time for 3 hours, combine the extracts, and filter.

[0042] S2: The filtrate is added to the pretreated X-5 macroporous adsorption resin column, the flow rate is controlled at 1BV / h, the effluent is discarded, and 12000mL of water is used as the impurity removal agent for impurity removal, the flow rate is 2.5BV / h, wash The removed impurity removal solution was discarded, and then 16000ml of 60% ethanol solution was used as the eluent for elution, the flow rate was 1BV / h, the collected eluate was concentrated under reduced pressure to syrup, the residue was added with diatomaceous earth, and crushed into fine pink:.

[0043] S3: Extract 5 times with methanol and dichloromethane mixture at a volume ratio of 1:8, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com