Water-based flash colored paint and preparation method thereof

A water-based paint technology, applied in the direction of metal-free paints, coatings, anti-corrosion coatings, etc., can solve the mechanical properties of paint films, poor chemical resistance, difficult to orientate water-based aluminum powder, and paint storage stability. Not strong and other problems, to achieve the effect of good random color effect, good flash effect and low VOC value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

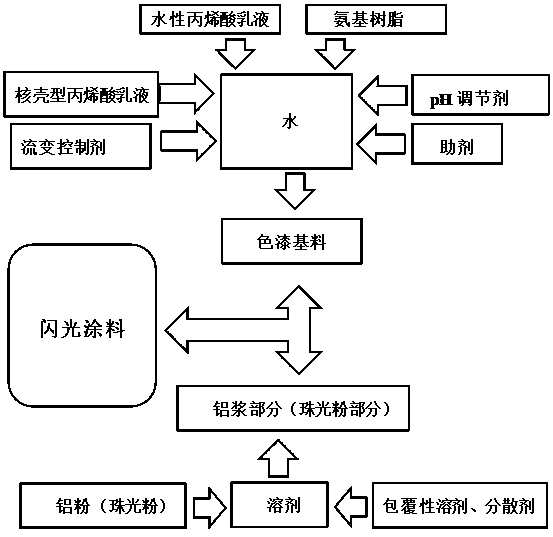

Method used

Image

Examples

Embodiment 1

[0033] Example 1, auxiliary tank, take a suitable container B, according to the mass fraction, first add 3 parts of water-based aluminum powder, then add 4.5 parts of solvent propylene glycol methyl ether, 4.5 parts of iso-octanol, stir at a low speed, add aluminum powder coating agent during the stirring process 1 part of polypropylene glycol, continue to stir for 20 minutes to make it fully mixed evenly, then let it stand for 30 minutes to make it ripen, and prepare a part of the aluminum paste for later use.

[0034] For the main cylinder, take a suitable container A, add 35 parts of water initially according to the mass fraction, start the disperser, disperse at a low speed, first add 5.5 parts of core-shell acrylic emulsion, then add 19 parts of water-based acrylic emulsion, self-crosslinking acrylic emulsion 17 parts, make it fully mixed evenly, add 0.2 parts of pH regulator, adjust the pH value to 8, then add 8.3 parts of methyl etherified high imino melamine resin. The...

Embodiment 2

[0036]Example 2, auxiliary tank, take a suitable container B, according to the mass fraction, first add 3 parts of water-based aluminum powder, then add 4.5 parts of solvent propylene glycol methyl ether, 4.5 parts of iso-octanol, stir at a low speed, add aluminum powder coating agent during the stirring process 1 part of polypropylene glycol, continue to stir for 20 minutes to make it fully mixed evenly, then let it stand for 30 minutes to make it ripen, and prepare a part of the aluminum paste for later use.

[0037] For the main cylinder, take a suitable container A, add 35 parts of water initially according to the mass fraction, start the disperser, and disperse at a low speed. 17 parts of non-toxic acrylic emulsion, make it fully mixed evenly, add 0.2 parts of pH adjuster, adjust the pH value to 8, and then add 8.3 parts of methyl etherified high imino melamine resin. Then add 0.7 parts of acetylene glycol defoaming wetting agent, add 1.3 parts of BASF RheovisAS 1130 rheo...

Embodiment 3

[0039] Example 3, auxiliary tank, take a suitable container B, according to the mass fraction, first add 3 parts of pearl powder, then add 4.5 parts of solvent propylene glycol methyl ether, 4.5 parts of isooctyl alcohol, stir at low speed for 20 minutes, make it fully mixed, and then statically Place it for 30 minutes to make it ripen to obtain the pearlescent powder part.

[0040] For the main cylinder, take a suitable container A, add 26 parts of water initially according to the mass fraction, start the disperser, disperse at a low speed, first add 5 parts of core-shell acrylic emulsion, then add 24 parts of water-based acrylic emulsion, self-crosslinking acrylic emulsion 22 parts, make it fully mixed evenly, add 0.2 parts of pH adjuster, adjust the pH value to 8, and then add 9 parts of methyl etherified high imino melamine resin. Then add 0.8 part of acetylenic diol antifoaming wetting agent, add rheology control agent 1 part of BASF Rheovis AS 1130, and disperse for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com