Composition for forming light emitting layer and organic electroluminescent element containing said composition for forming light emitting layer

A light-emitting layer and composition technology, applied in the field of light-emitting layer-forming compositions and organic electroluminescent elements, can solve problems such as insufficient research, and achieve the effects of long driving life and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

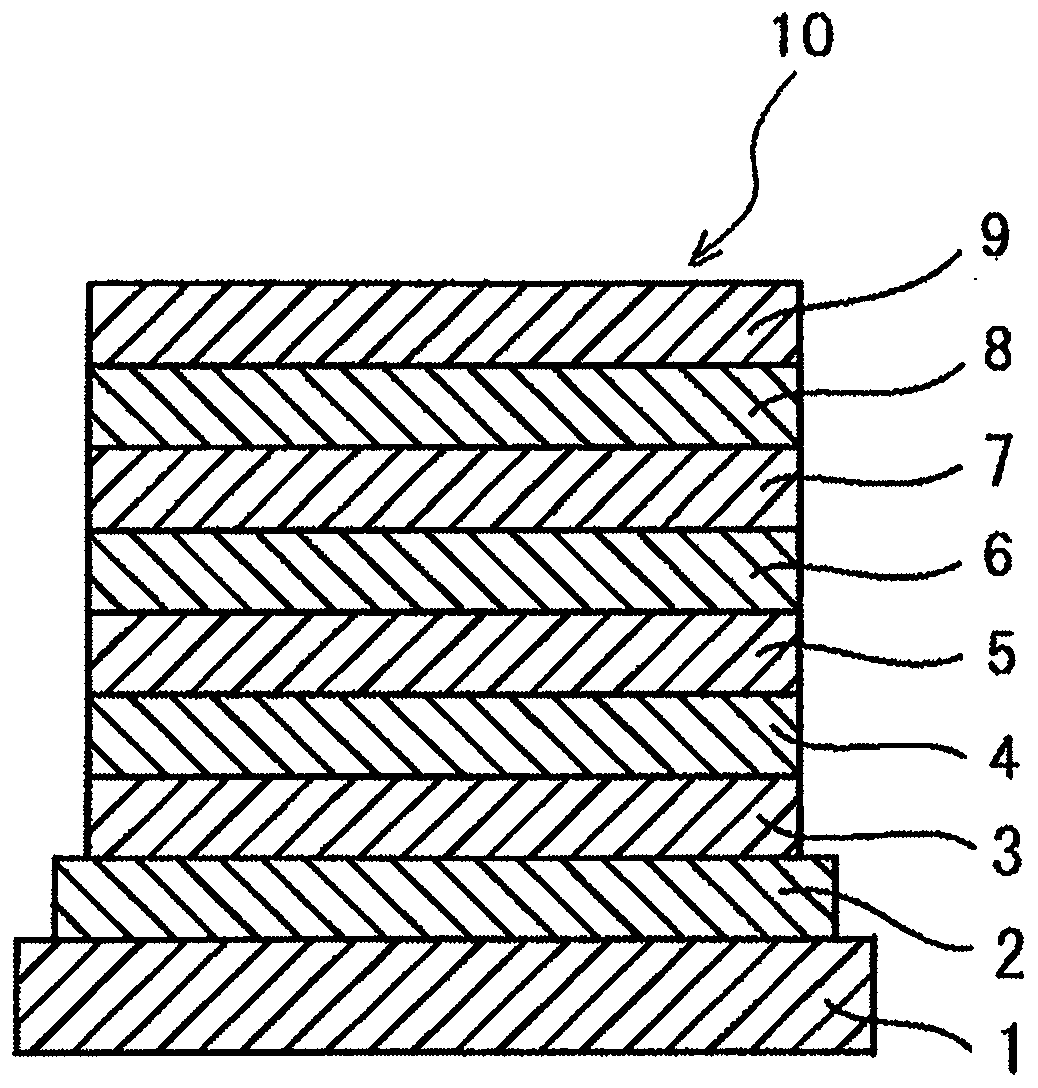

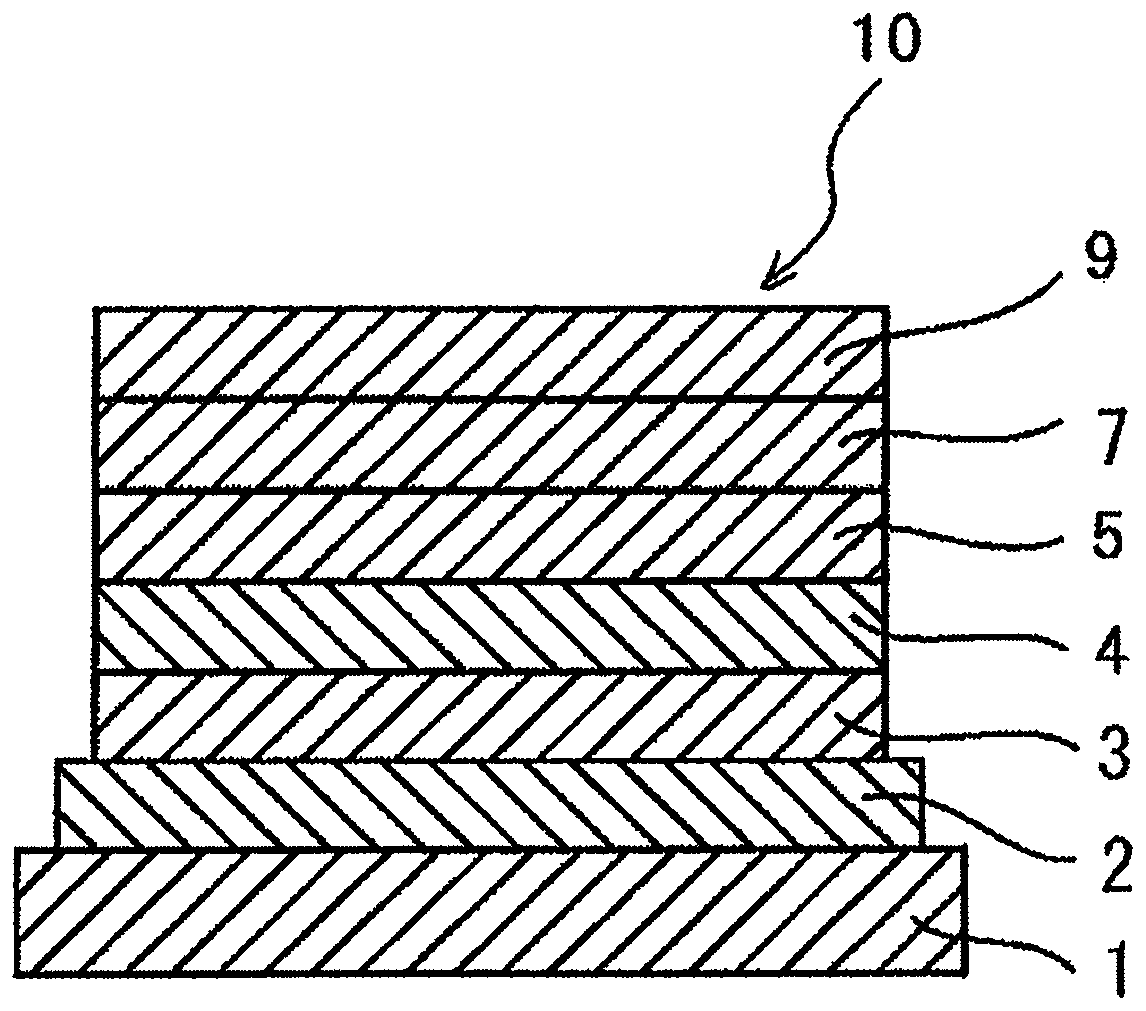

[0253] make figure 1 The organic electroluminescence element of the composition shown.

[0254]

[0255] On the substrate 1 made of glass, a film (sputtering film-formed product, sheet resistance 15Ω) formed by forming an indium tin oxide (ITO) transparent conductive film with a thickness of 70 nm is patterned to a width of 2 mm by a common photolithography technique. The stripes form the anode 2. After cleaning the substrate 1 (ITO substrate) with the anode 2 in the order of ultrasonic cleaning with pure water and washing with pure water, it was dried by blowing nitrogen gas, and finally ultraviolet ozone cleaning was performed.

[0256]

[0257] Next, the hole injection layer 3 was formed by a wet film-forming method as follows.

[0258] Prepare 2.0% by mass of a polymer compound (weight average molecular weight 52000) having a repeating structure represented by the following formula (P1) as a hole-transporting compound, and 4-isopropyl-4'- as an electron-accepting com...

Embodiment 2

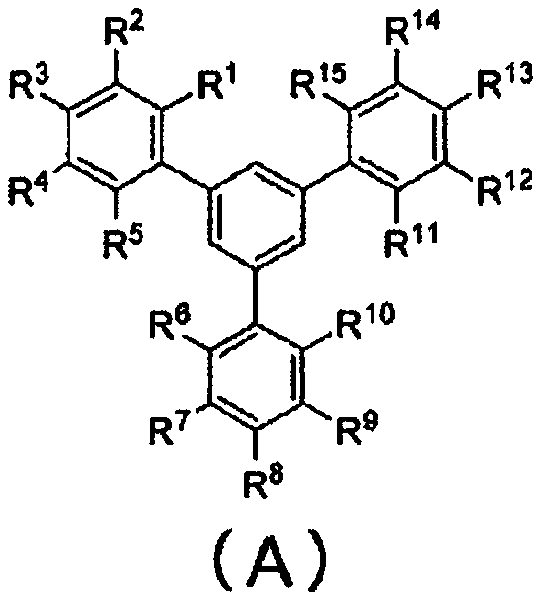

[0292] In Example 1, as the non-luminescent material and light-emitting material contained in the composition for forming a light-emitting layer, compound (HH-2), compound (LH-1), compound (LH-2), compound (H -1) Except having mixed the compound (D-1) at the mass ratio of 15:15:15:55:15, it carried out similarly to Example 1, and produced the organic electroluminescence element. In addition, compound (LH-2) is a compound which has the structure shown below, Tg is 87 degreeC, and molecular weight is 762.3. In addition, the content of the low Tg compound relative to the total amount of all non-luminescent materials contained in the composition for forming a light-emitting layer was 30% by mass, and the weighted average glass transition temperature of all non-luminescent materials was 110°C.

[0293]

Embodiment 3

[0295] In Example 1, as the non-luminescent material and light-emitting material contained in the composition for forming a light-emitting layer, compound (HH-1), compound (H-2), compound (H-3), compound (LH -1) and compound (D-1) were mixed at the mass ratio of 35:15:35:15:15, and the organic electroluminescence element was produced similarly to Example 1 except this. In addition, compound (H-2) and compound (H-3) are compounds which have the structure shown below, Tg is 129 degreeC, 109 degreeC, respectively, and molecular weight is 791.3 and 1157.5, respectively. The content of the low Tg compound relative to the total amount of all non-luminescent materials contained in the composition for forming a light-emitting layer was 15% by mass, and the weighted average glass transition temperature of all non-luminescent materials was 127°C.

[0296]

[0297]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap