Bottom-layer blood platelet factor patch and preparation method of sPL blood platelet factor gel patch membrane

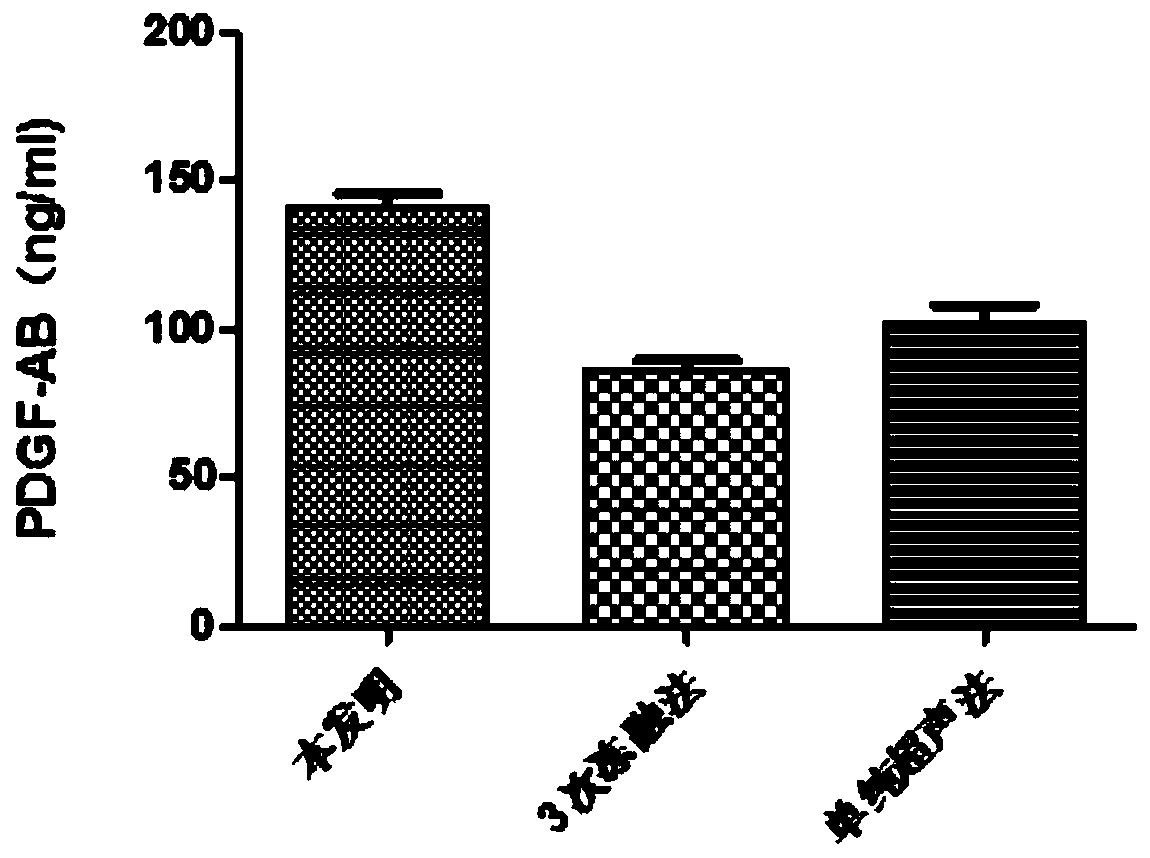

A platelet factor and underlying technology, which is applied in blood diseases, pharmaceutical formulations, inactive components of polymer compounds, etc., can solve the problems of uneven composition, uneven thickness, and indeterminate shape of platelet factor film, which is convenient for operation and emergency. The effect of using and reducing the content of key factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

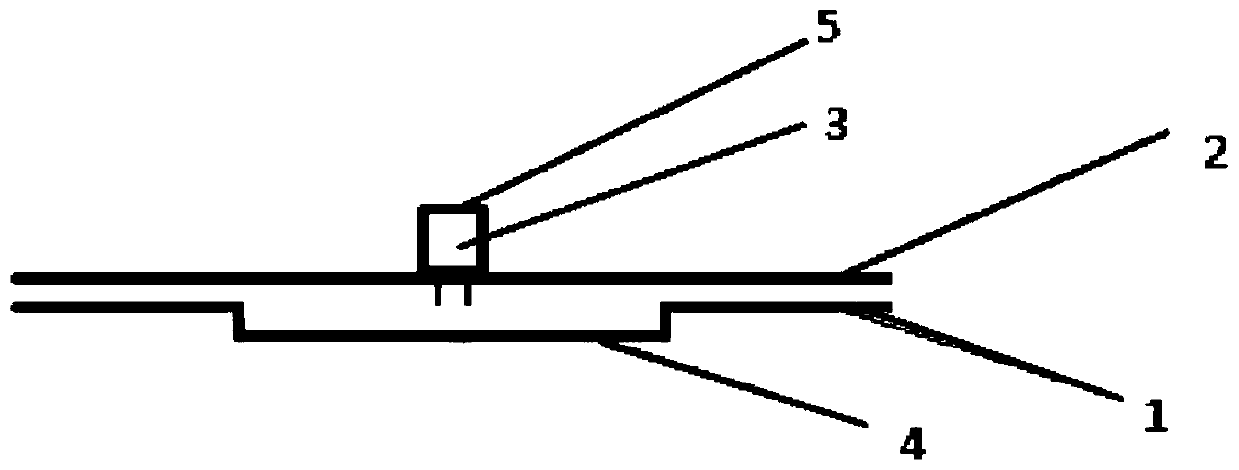

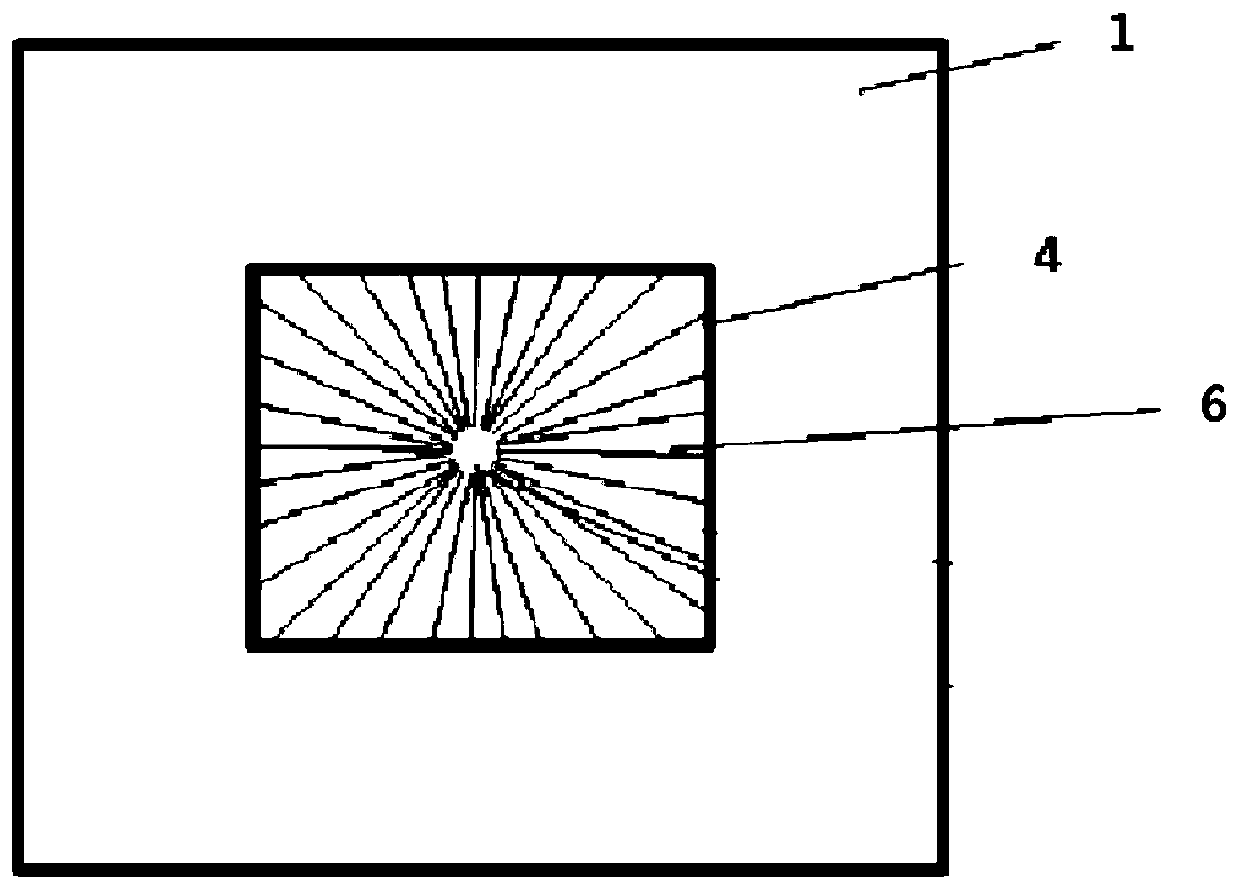

[0031] Embodiment 1: In this embodiment, a bottom-layer platelet factor patch includes a bottom-layer lining film 1 and an upper-layer covering film 2, and the upper-layer covering film 2 covers the bottom-layer lining film 1; the middle area of the bottom-layer lining film 1 is depressed downward to form platelets The factor bearing area 4, the platelet factor bearing area is provided with diversion ribs; the upper cover film 2 is provided with a liquid inlet 3, and the liquid inlet 3 is provided with a sealing cover 5; wherein the liquid inlet 3 is located in the platelet factor bearing area directly above the center.

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment differs from Embodiment 1 in that: the liquid inlet 3 is threadedly connected to a pressure syringe with a sterile threaded port. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the depth of the platelet factor bearing region 4 is 3 mm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com