Powder-mesh composite material and processing method thereof

A composite material and wire mesh technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as insufficient filtration accuracy and poor regeneration performance, and achieve improved filtration accuracy, high flow rate, and flexibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

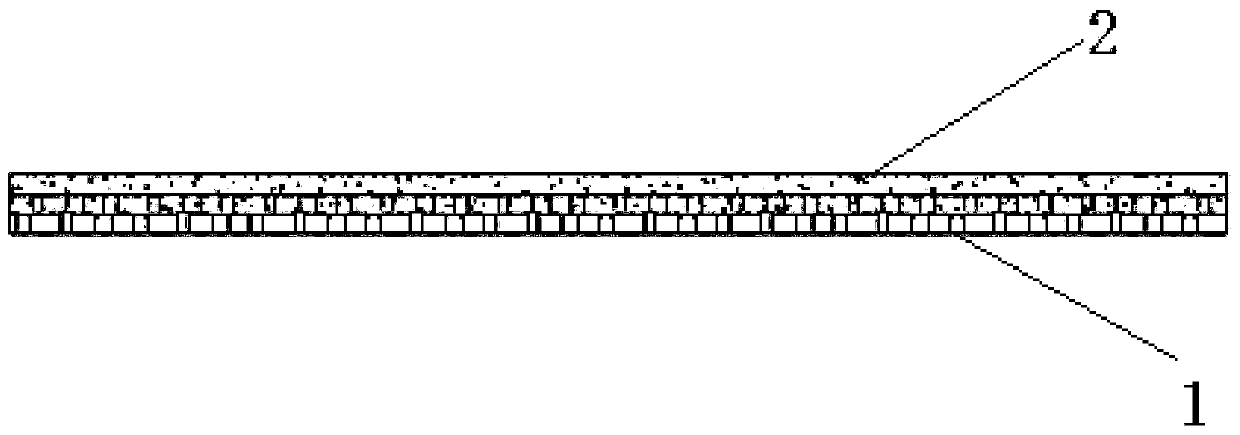

[0026] The method for preparing a powder-net composite material of the present invention is specifically implemented according to the following steps:

[0027] Step 1: Lay out the metal wire mesh 1 into a flat shape;

[0028] Step 2: Lay a layer of metal or metal compound powder on the metal wire mesh obtained in step 1, and add 2-10% binder to the metal or metal compound powder to obtain a prefabricated material;

[0029] Step 3: The prefabricated material obtained in step 2 is rolled, vacuum sintered and insulated to obtain a powder mesh composite material for filtration.

[0030] Among them, the binder is one of resin, PVB, and PEG, the sintering temperature is 900-1150°C, and the heat preservation is 30-60 minutes.

Embodiment 1

[0032] A powder mesh composite material, including stainless steel wire mesh and porous stainless steel metal film attached to the stainless steel wire mesh. The stainless steel wire mesh has a single-layer structure of 120X400. The porous stainless steel metal film has a thickness of 0.2mm, a hole diameter of 2μm, and an air permeability of 100m. 3 / (㎡·kPa·h).

[0033] In this embodiment, a method for preparing a powder-net composite material, the specific implementation process is as follows:

[0034] Step 1: Lay out the 120X400 stainless steel single-layer wire mesh into a flat shape;

[0035] Step 2: On the stainless steel wire mesh obtained in step 1, a layer of porous stainless steel metal powder with a thickness of 0.2mm and an average particle size of 5-10μm is laid, and 5% by mass phenolic resin is added for bonding. Knot, and finally get the prefabricated material;

[0036] Step 3: After rolling the preformed material obtained in step 2 through a rolling mill, it is put into...

Embodiment 2

[0038] A powder mesh composite material, comprising iron-chromium-aluminum alloy wire mesh and porous iron-aluminum alloy film attached to the iron-chromium-aluminum alloy wire mesh. The chromium-aluminum alloy wire mesh has a single-layer structure of 200 meshes and the thickness of the porous iron-aluminum alloy film is 0.3 mm, average pore diameter is 0.5μm, air permeability is 50m 3 / (㎡·kPa·h).

[0039] In this embodiment, a method for preparing a powder-net composite material, the specific implementation process is as follows:

[0040] Step 1: Lay out a single layer of 200 mesh iron-chromium-aluminum alloy wire mesh;

[0041] Step 2: Lay a layer of porous iron-aluminum alloy powder with a thickness of 0.3mm and an average particle size of 5-10μm on the formed iron-chromium-aluminum alloy wire mesh obtained in step 1, and add 3% by mass to it PVC is used for bonding, and finally the prefabricated material is obtained;

[0042] Step 3: After rolling the prefabricated material obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com