Gasoline purification synergist as well as preparation method and use method thereof

A technology of synergist and production method, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of low engine efficiency, poor carbon removal effect, and excessive exhaust gas, so as to improve combustion performance and reduce The effect of carbon deposition, water reduction and tail gas emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

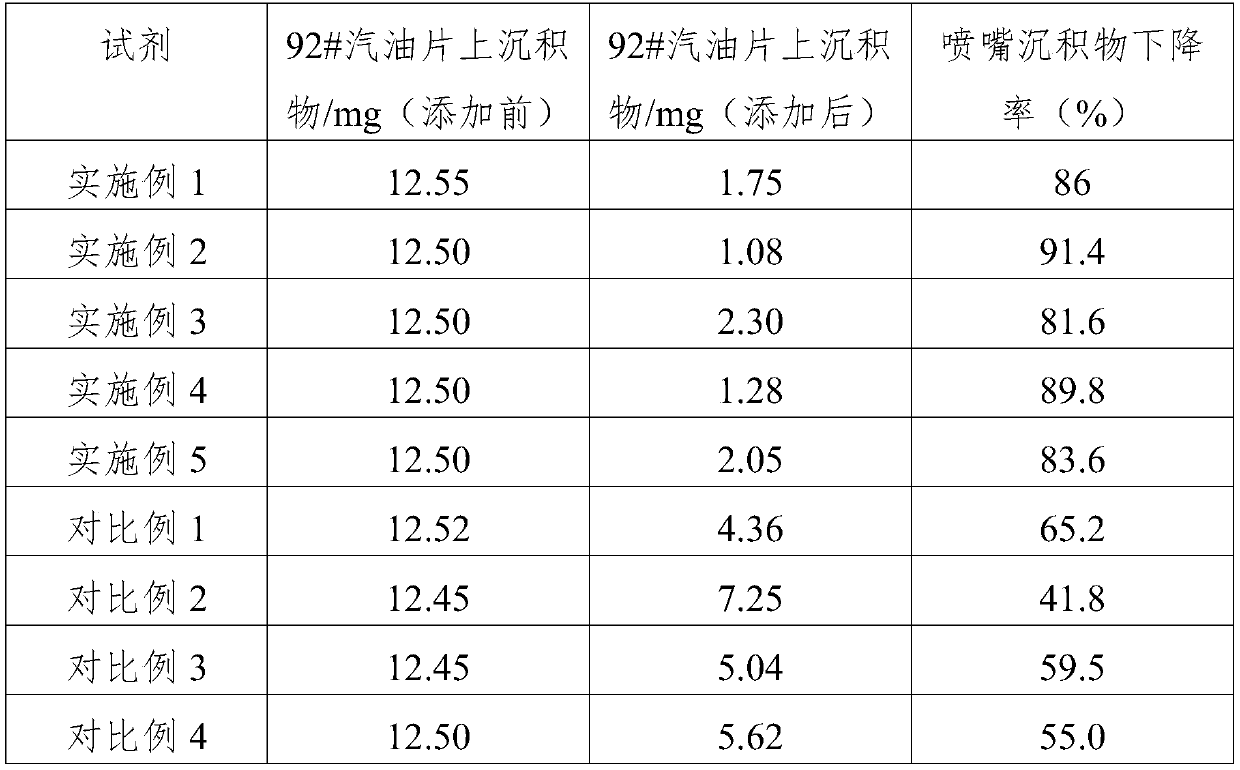

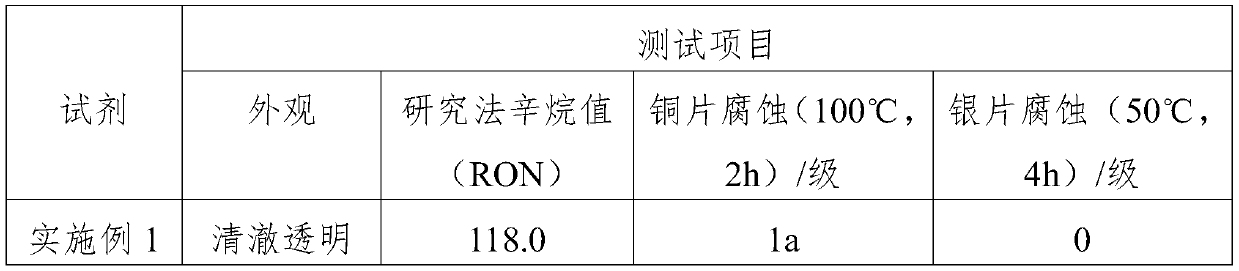

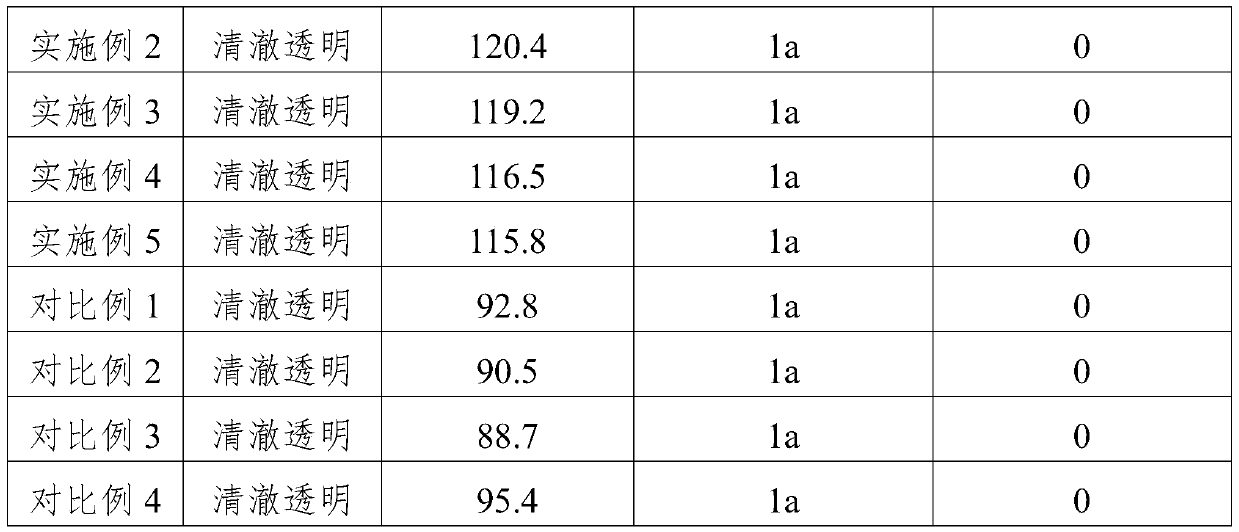

Examples

Embodiment 1

[0038] The preparation method of the gasoline detergent synergist of the present embodiment may further comprise the steps:

[0039] 1) Dissolving 0.001% sodium hydroxide in 0.51% absolute ethanol, stirring fully until the solution is clear and free of solid insolubles, to obtain the first mixture;

[0040] 2) Add 0.22% of 3-methyl-1-butene, 0.27% of methyl tert-butyl ether, 0.08% of hydrogenated castor oil, 9.2% of triethanolamine, 1% of polyisobuteneamine, polyether 10% of amine, 1.2% of graphene, 0.8% of lauryl alcohol, 0.3% of antioxidant T501, and 0.25% of methylal were mixed and stirred evenly to obtain the second mixture;

[0041] 3) Add the remaining amount of jet fuel to the above-mentioned second mixture, and stir for 25 minutes to make a gasoline detergent synergist.

Embodiment 2

[0043] The preparation method of the gasoline detergent synergist of the present embodiment may further comprise the steps:

[0044] 1) Dissolving 0.002% sodium hydroxide in 0.4% absolute ethanol, stirring fully until the solution is clear and free of solid insoluble matter, to obtain the first mixture;

[0045] 2) Add 0.25% of 3-methyl-1-butene, 0.25% of methyl tert-butyl ether, 0.1% of hydrogenated castor oil, 9.3% of triethanolamine, 2% of polyisobuteneamine, polyether 10% of amine, 1.5% of graphene, 0.8% of lauryl alcohol, 0.25% of antioxidant T501, and 0.3% of methylal were mixed and stirred evenly to obtain the second mixture;

[0046] 3) Add the remaining amount of jet fuel to the above-mentioned second mixture, and stir for 30 minutes to make a gasoline detergent synergist.

Embodiment 3

[0048] The preparation method of the gasoline detergent synergist of the present embodiment may further comprise the steps:

[0049] 1) Dissolve 0.002% sodium hydroxide in 0.38% absolute ethanol, stir well until the solution is clear and free of solid insoluble matter, to obtain the first mixture;

[0050] 2) Add 0.24% of 3-methyl-1-butene, 0.25% of methyl tert-butyl ether, 0.15% of hydrogenated castor oil, 9.3% of triethanolamine, 1.5% of polyisobuteneamine, polyether Amine 9%, graphene 1%, lauryl alcohol 0.8%, antioxidant T501 0.25%, and methylal 0.27% were mixed and stirred evenly to obtain the second mixture;

[0051] 3) Add the remaining amount of jet fuel to the above-mentioned second mixture, and stir for 25 minutes to make a gasoline detergent synergist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com