Preparation method of lithium nickel manganese oxide positive electrode material coated with a strontium titanate-based conductive coating

A technology of lithium nickel manganese oxide and cathode materials, which is applied in the field of preparation of cathode materials for lithium-ion batteries, can solve problems such as difficult to precisely control the ratio of elements, unfavorable large-scale industrial production, and complicated preparation processes, so as to improve high-temperature charge and discharge performance, Reduction of phase transition and agglomeration, low transmission energy barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

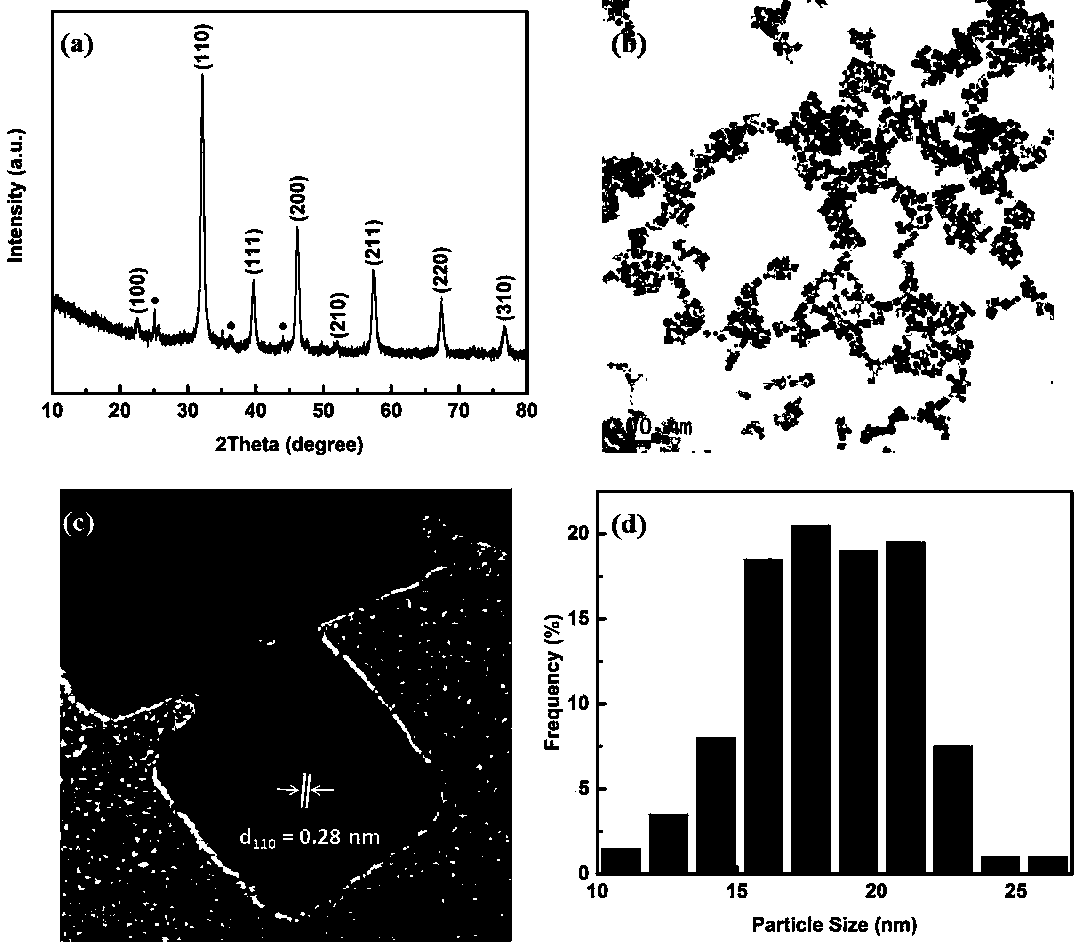

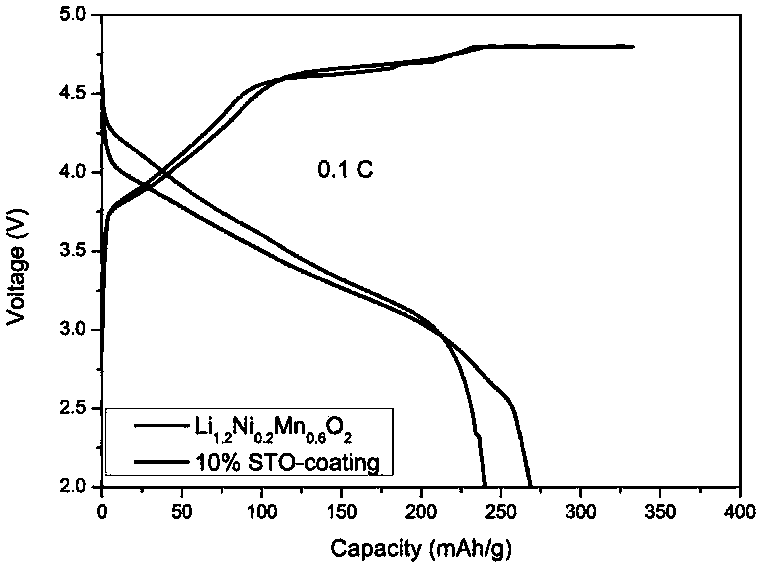

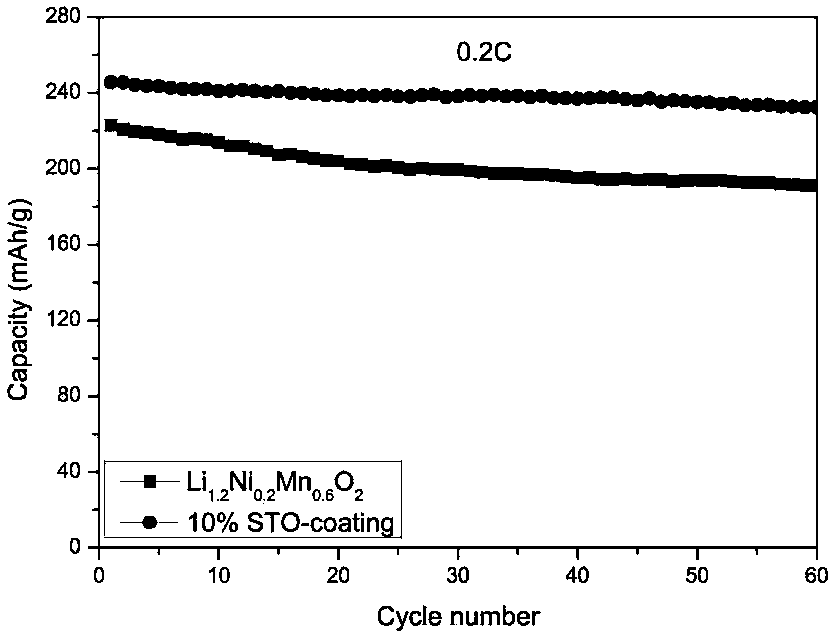

Image

Examples

Embodiment 1

[0034] A preparation method of a conductive strontium titanate coating lithium nickel manganese oxide positive electrode material, comprising the following steps:

[0035] (1) take by weighing strontium hydroxide and tetrabutyl titanate by the molar ratio of 1:1;

[0036] (2) Dissolve strontium hydroxide and tetrabutyl titanate in triethylene glycol, heat to 80°C, and dissolve them fully to obtain a mixed solution A;

[0037] (3) The mass ratio of strontium hydroxide and tetrabutyl titanate total mass to lithium nickel manganese oxide positive electrode material is 10:90 to take lithium nickel manganese oxide positive electrode material;

[0038] (4) Under the condition that the temperature of the mixed solution A is 80°C and the rotational speed of the stirrer is 300r / min, the lithium nickel manganese oxide positive electrode material is added to the mixed solution A while adding 0.5% polyvinylpyrrolidone of triethylene glycol weight, the molecular weight 36000, mechanically...

Embodiment 2

[0043] A preparation method containing conductive strontium titanate coating lithium nickel manganese oxide positive electrode material, comprising the following steps:

[0044] (1) take by weighing strontium hydroxide and tetrabutyl titanate by the molar ratio of 1:1;

[0045] (2) Dissolve strontium hydroxide and tetrabutyl titanate in triethylene glycol, heat to 80°C, and dissolve them fully to obtain a mixed solution A;

[0046] (3) Under the condition that the temperature of the mixed solution A is 80°C and the rotational speed of the stirrer is 300r / min, the lithium nickel manganese oxide positive electrode material is added to the mixed solution A while adding 0.4% polyvinylpyrrolidone of triethylene glycol weight, the molecular weight 50000, mechanically stirred for 30 minutes to obtain mixed suspension B;

[0047](4) at 80 DEG C, under the mechanical stirring condition of 300r / min, add ammoniacal liquor in mixed suspension B, the amount of ammoniacal liquor is 7 times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com