Low-GI (glycemic index) multi-grain instant meal replacement powder and preparation method thereof

A meal replacement powder and grain technology, applied in the field of low GI multi-grain instant meal replacement powder and its preparation, can solve the problems of poor palatability, difficult cooking, etc., and achieve the goal of retaining nutrients, simplifying the production process, and low GI value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

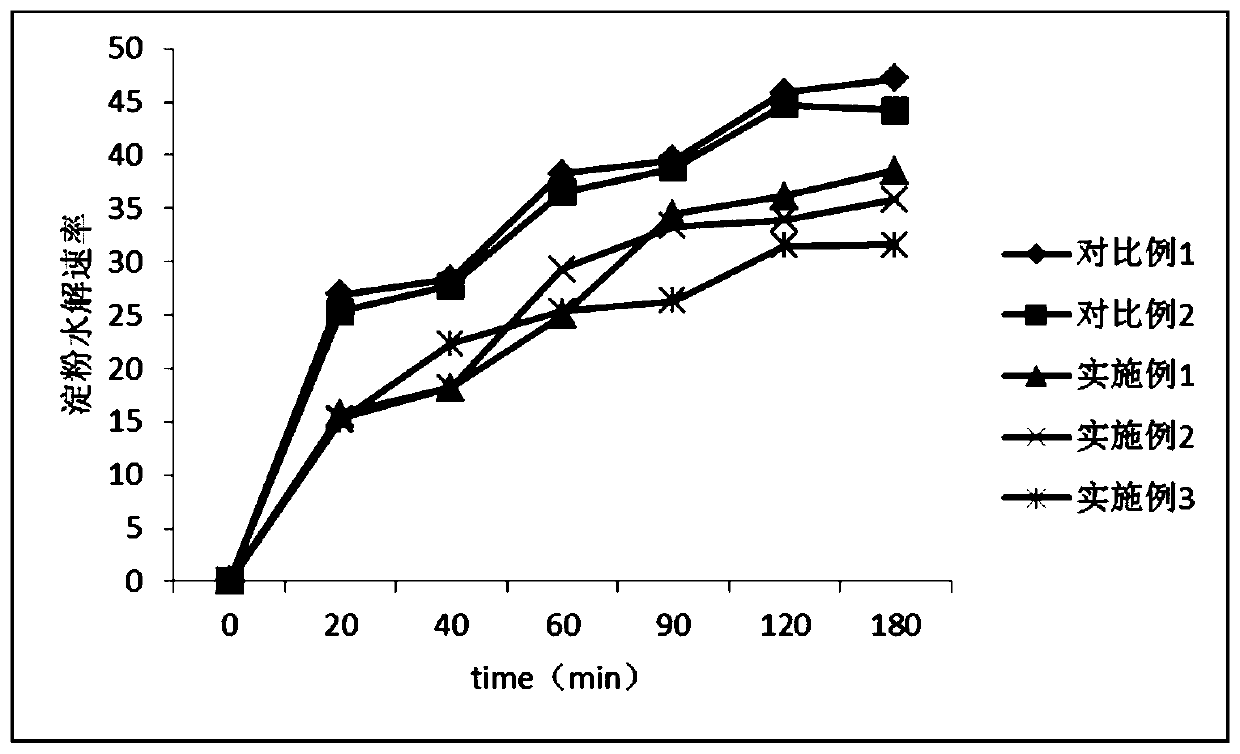

Embodiment 1

[0037] A low GI multi-grain instant meal replacement powder is prepared from 11.5 parts of quinoa, 4 parts of oats, 22 parts of highland barley, 7.5 parts of mung beans, 30 parts of millet and 25 parts of tartary buckwheat.

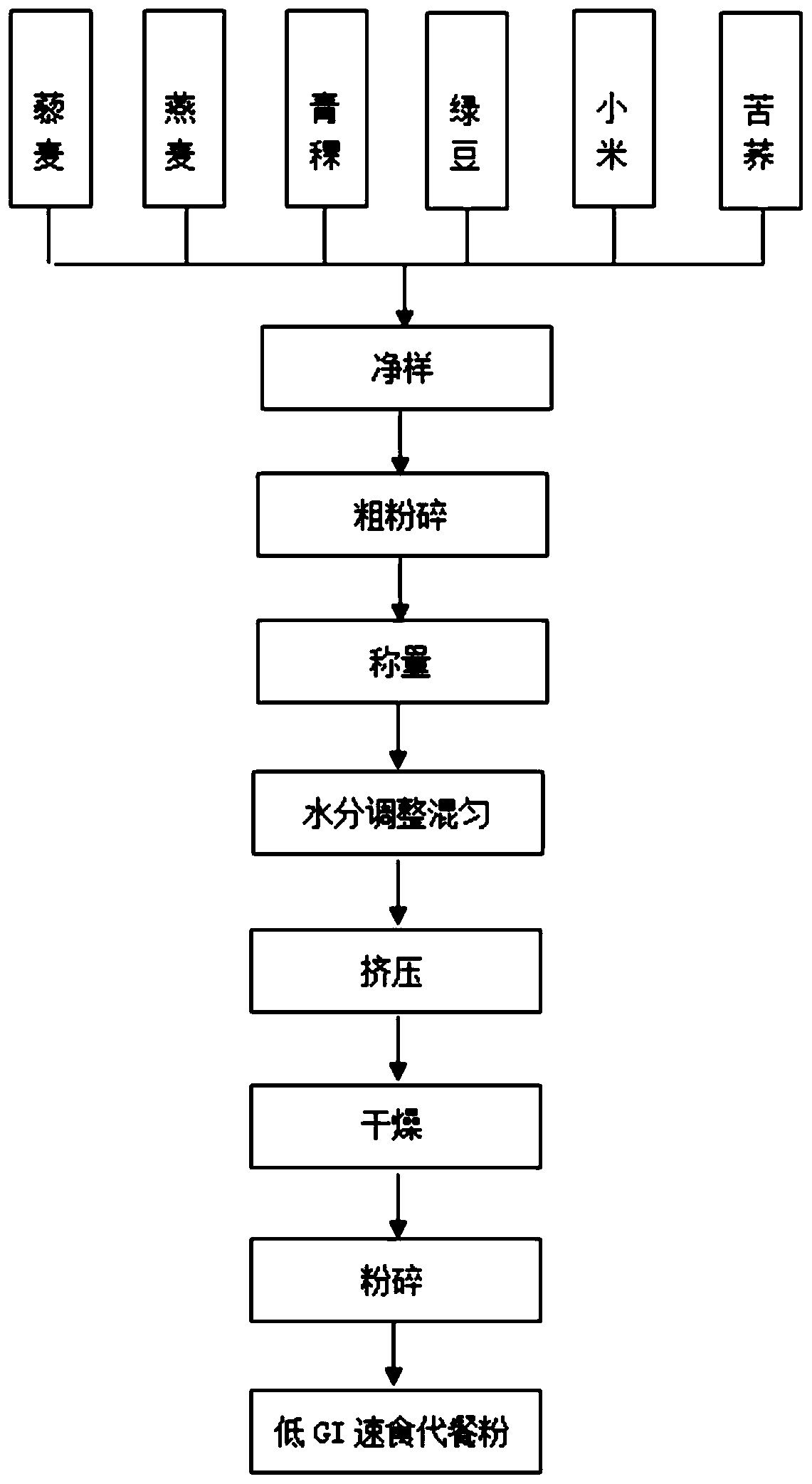

[0038] The preparation method specifically comprises the following steps:

[0039] (1) The raw materials of quinoa, oats, highland barley, mung bean, millet and tartary buckwheat are prepared for use;

[0040] (2) Pulverize the miscellaneous grains raw material in step (1) respectively with a pulverizer, then cross a 60-mesh sieve to make miscellaneous grains powder;

[0041] (3) Take the miscellaneous grain powder in the step (2) by weight and put it into a blender for mixing, then add 17% pure water and stir, stir evenly and set aside;

[0042] (4) Send the mixed powder prepared in step (3) into the twin-screw extruder and extrude in four stages. The extrusion temperatures of the four stages are 60°C, 80°C, 120°C, and 170°C respectively 270r / min, get ...

Embodiment 2

[0046] A low GI multi-grain instant meal replacement powder is prepared from 10.5 parts of quinoa, 3.5 parts of oats, 21 parts of highland barley, 7 parts of mung beans, 28 parts of millet and 30 parts of tartary buckwheat.

[0047] The preparation method specifically comprises the following steps:

[0048] (1) The raw materials of quinoa, oats, highland barley, mung bean, millet and tartary buckwheat are prepared for use;

[0049] (2) Pulverize the miscellaneous grains raw material in step (1) respectively with a pulverizer, then cross a 60-mesh sieve to make miscellaneous grains powder;

[0050] (3) Take the miscellaneous grain powder in the step (2) by weight and put it into a blender to mix, then add 18% pure water and stir, stir evenly and set aside;

[0051] (4) Send the mixed powder prepared in step (3) into the twin-screw extruder and extrude in four stages. The extrusion temperatures of the four stages are 60°C, 90°C, 130°C, and 180°C respectively 290r / min, get puff...

Embodiment 3

[0055] A low GI multi-grain instant meal replacement powder is prepared from 10 parts of quinoa, 3.5 parts of oats, 19 parts of highland barley, 6.5 parts of mung beans, 26 parts of millet and 35 parts of tartary buckwheat.

[0056] The preparation method specifically comprises the following steps:

[0057] (1) The raw materials of quinoa, oats, highland barley, mung bean, millet and tartary buckwheat are prepared for use;

[0058] (2) Pulverize the miscellaneous grains raw material in step (1) respectively with a pulverizer, then cross a 60-mesh sieve to make miscellaneous grains powder;

[0059] (3) Take the miscellaneous grain powder in the step (2) by weight and put it into a blender for mixing, then add 16% pure water and stir, stir evenly and set aside;

[0060] (4) Send the mixed powder prepared in step (3) into the twin-screw extruder and extrude in four stages. The extrusion temperatures of the four stages are 60°C, 90°C, 130°C, and 190°C respectively 290r / min, get ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com