Preparation method of dielectric gradient material and potting method of electronic components

A technology of electronic components and gradient materials, which is applied in the field of insulating material preparation, can solve the problems of uneven and large gradient dielectric distribution, inability to provide, and limited increase in dielectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

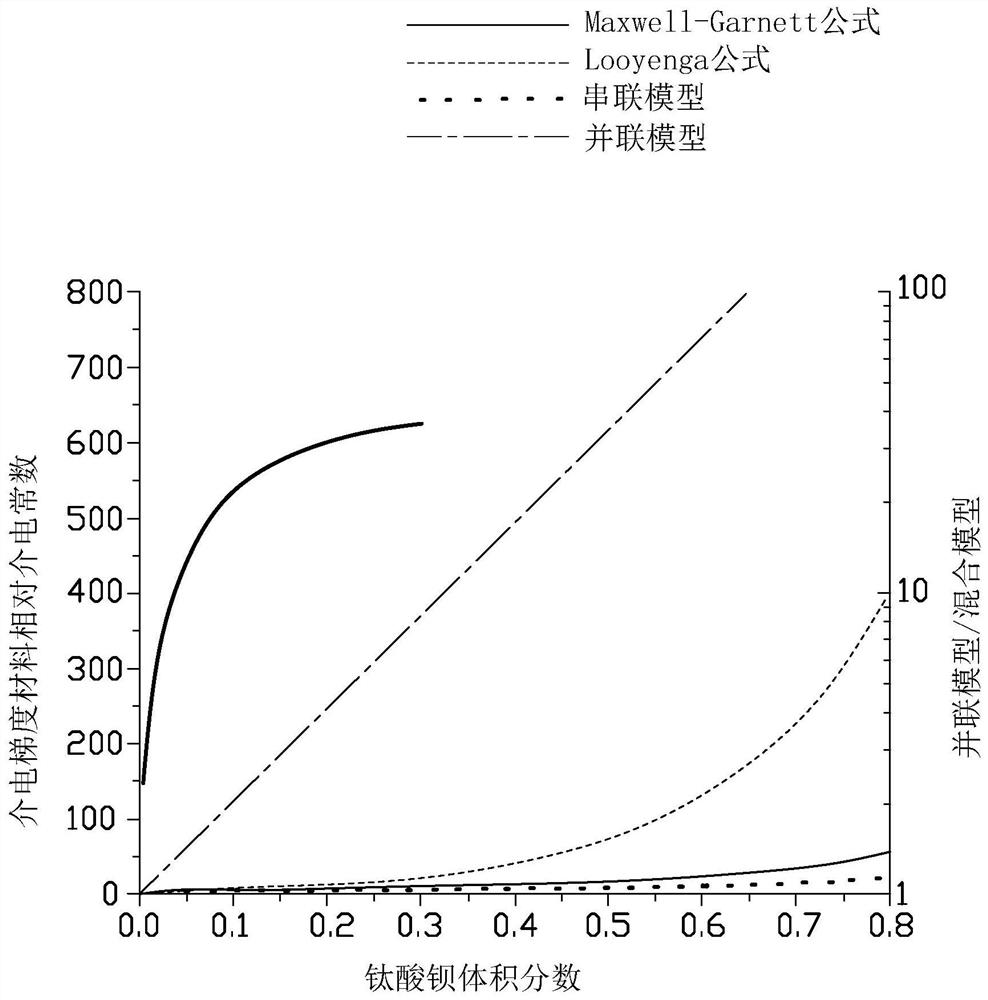

[0040] see figure 1, a method for preparing a dielectric gradient material based on magnetic field induction provided by an embodiment of the present invention, comprising the following steps:

[0041] Step S1: mixing inorganic particles and liquid organic matter to obtain a suspension, the inorganic particles include at least one magnetic material with a dielectric constant greater than 40;

[0042] Step S2: applying a magnetic field to the suspension, under the action of the magnetic field, the magnetic field force on some of the inorganic particles is greater than the viscous resistance on the part of the inorganic particles in the suspension, so that The part of the inorganic particles is arranged in a chain along the direction of the magnetic field;

[0043] Step S3: performing solidification treatment on the suspension after applying the magnetic field to solidify the suspension to obtain the dielectric gradient material.

[0044] The inorganic particles are dispersed ...

Embodiment

[0120] Add the photosensitive bisphenol A type epoxy acrylate resin and the defoamer TL-X60 into the mixing tank according to the ratio of 100:0.4 in parts by mass to obtain the mixed solution, stir at a speed of 600r / min for 0.5h in an ultrasonic environment, and Degas in a vacuum environment at 50°C for 0.5h.

[0121] Add the mixture, barium titanate@ferric oxide core-shell particles with a particle size of 1 μm and KH-560 silane coupling agent into the mixing tank according to the ratio of 100:2.5:0.0375 in parts by mass, and in an ultrasonic environment Stirring at a speed of 600 rpm for 0.5 hours, and degassing in a vacuum environment at 50°C for 0.5 hours to obtain a suspension, wherein, converted into a volume fraction, barium titanate@ferric oxide accounts for 1% of the total volume of the suspension 0.5%.

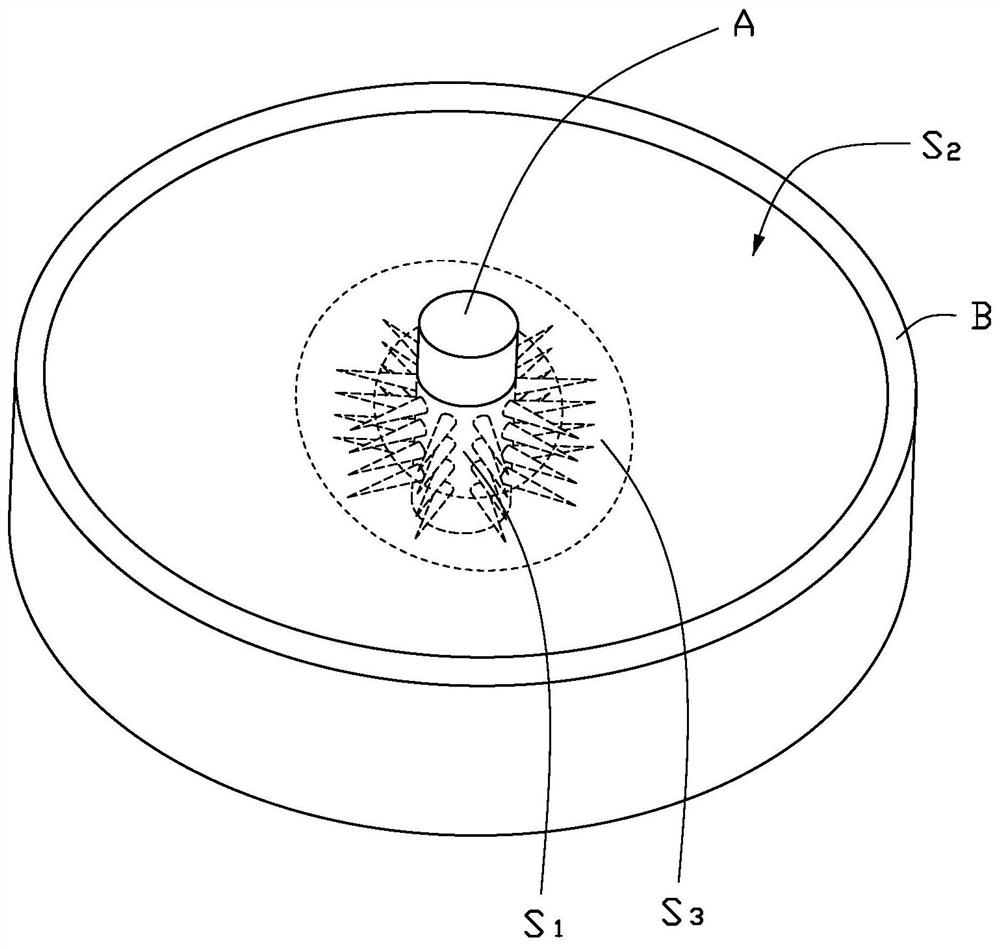

[0122] see Figure 4 , put the suspension in a disc-shaped mold, the disc-shaped mold is made of polytetrafluoroethylene material, the surface is coated with Jia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com