Processing method of recycled polystyrene waste

A technology of polystyrene and additives, which is applied in the processing field of recycled polystyrene, can solve problems such as inability to prepare, and achieve the effect of large volume and saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0173] Recycling of polystyrene waste

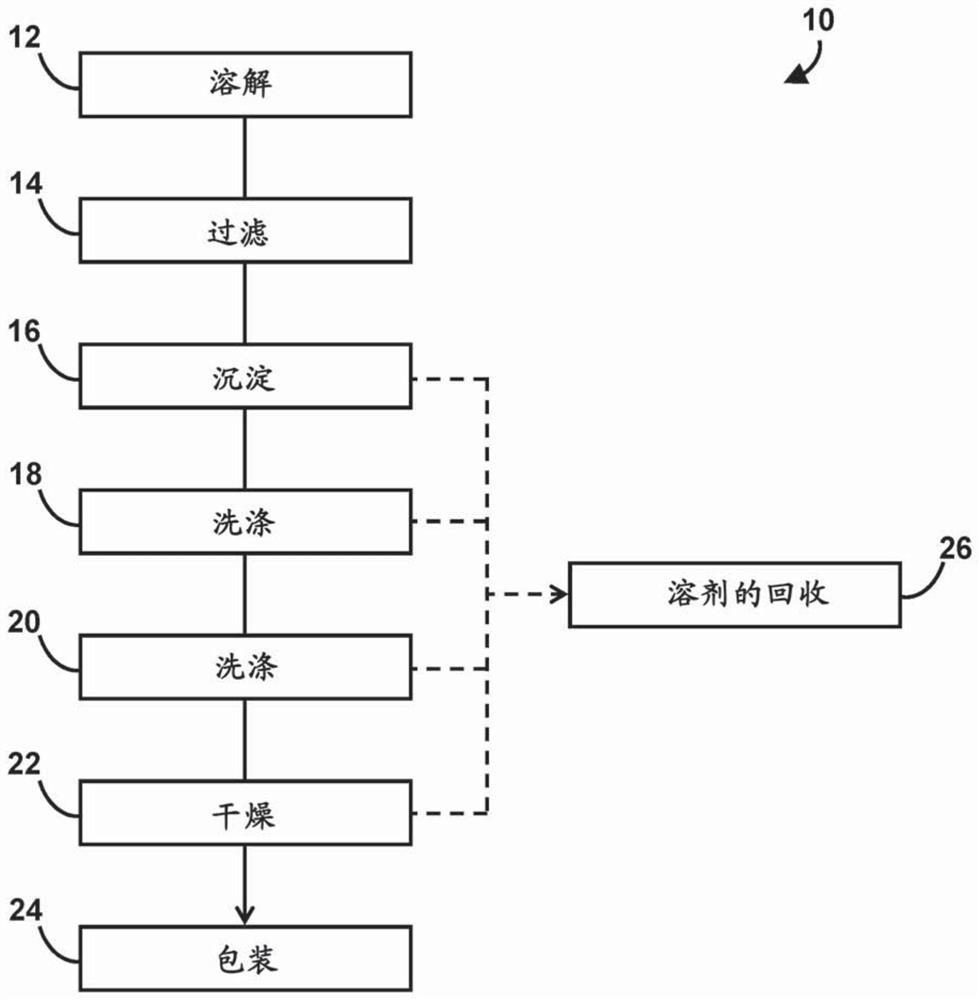

[0174] In this study, polystyrene waste was recovered by a method comprising five main steps according to the following sequence:

[0175] 1. Dissolve polystyrene in p-cymene

[0176] 2. Filter the PS / p-cymene mixture to remove undissolved material

[0177] 3. Wash with a non-polar solvent that is not a solvent for PS

[0178] 4. Dry

[0179] 5. Forming and Packaging PS Plastic Beads

[0180] In the first step (dissolution), polystyrene waste such as industrial post-consumer expanded polystyrene is dissolved in p-cymene (1-methyl-4-(1-methylethyl)benzene, which is One of the three possible isomers of cymene, and the only one that exists in nature). The solubility limit for polystyrene in p-cymene is 33% (w / w) or 28.5% (v / v) at room temperature, and the density of the polystyrene / p-cymene mixture reaches a value of 1.06 kg / L , this value is higher than the density of pure p-cymene, the density of pure p-cymene is 0.86kg / L. Reaching...

Embodiment 2

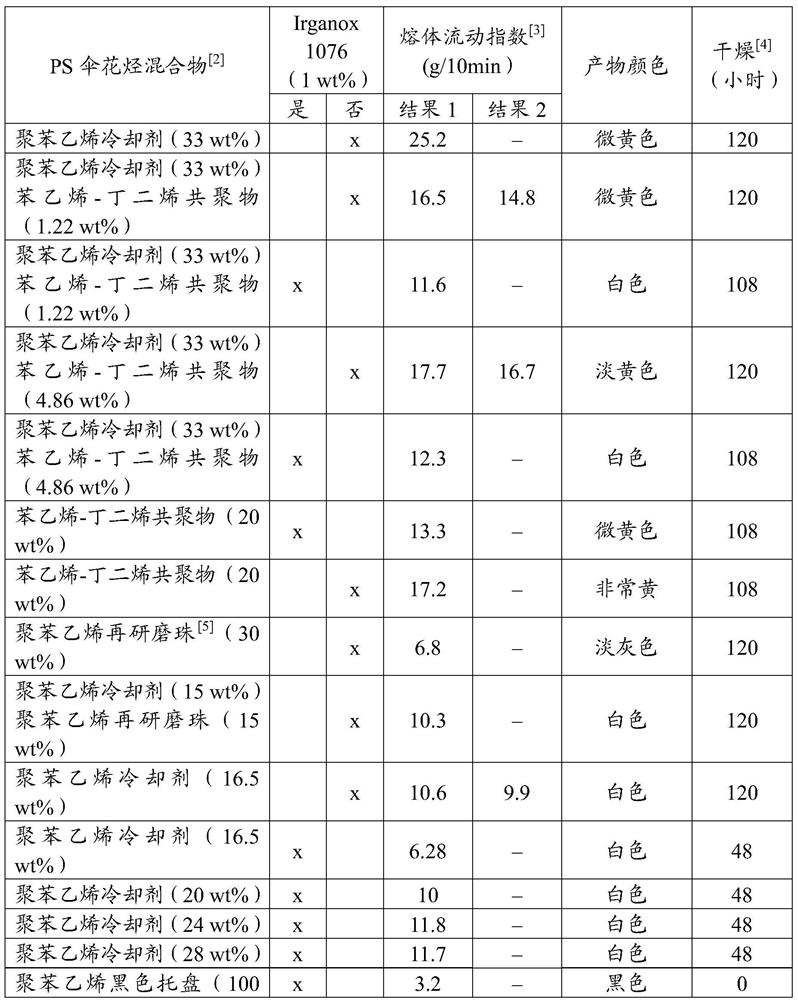

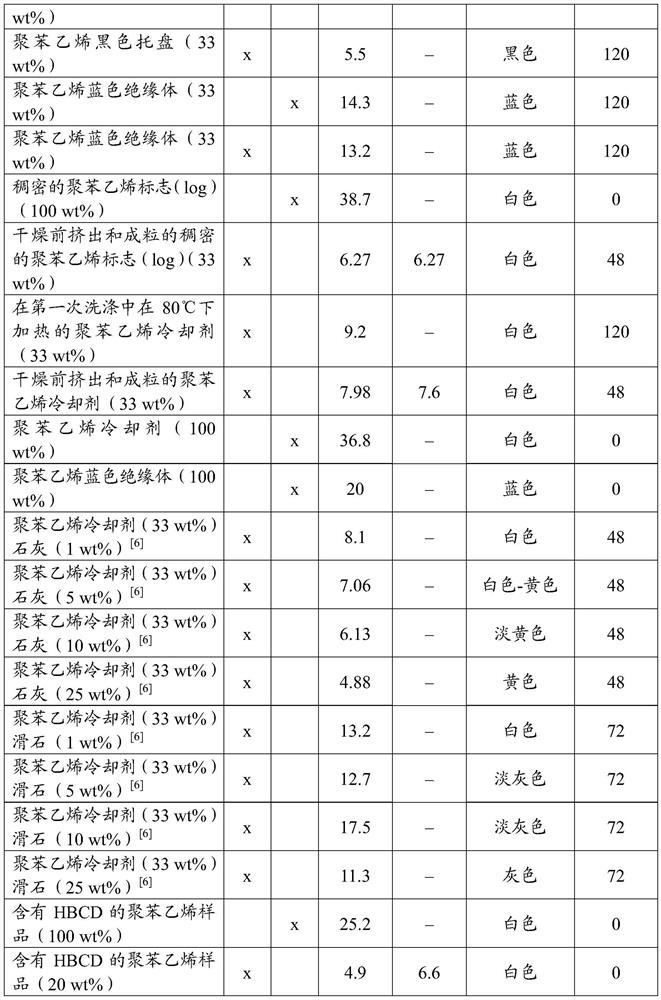

[0216] Further testing was performed to produce recycled polystyrene. Such tests were performed by using a method similar to that previously described in Example 1 but without adding any Irganox. These tests are performed at laboratory scale on true white expanded polystyrene used for packaging.

[0217] Accordingly, the results of such tests are provided below

[0218] DSC (ASTM D3418): T g =108.1℃

[0219] IZOD impact test (ASTM D4812): The average impact of 4 tests is 13,78KJ / m 2 and 175,72J / m, energy = 0,55J with full fracture

[0220] Table 4: MFI Testing

[0221] MFI (ASTM D1238 of Dynisco D4002 at 200°C):

[0222] test MFI(g / 10min) 1 11.44 2 11.01 3 10.70 average 11.05

[0223] Ash content (ASTM D5630): 0.10

[0224] Table 5: VICAT Test

[0225] VICAT softening temperature (ASTM D1525):

[0226]

[0227] Table 6: VICAT Test

[0228] Traction Test (ASTM D638)

[0229]

Embodiment 3

[0231] Further tests were conducted to produce recycled polystyrene. Such tests were performed by using methods similar to those previously described in Example 1 . The process is carried out continuously, scaling up the process from the laboratory level to the industrial level. For example, the method allows the production of about 10 kg of recycled polystyrene per hour. It should be noted that the limiting factor regarding the productivity of the method in this case does not lie in the method itself, but in certain types of equipment used to carry out the method. The overall process can easily achieve about 500 to about 1000 kg of recovered polystyrene per hour by obtaining some equipment that allows to accept larger volumes or larger quantities.

[0232] Accordingly, the results of such tests are provided below.

[0233] According to ASTM D1238-13 standard, MFI=22g / 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com