Super-hydrophobic nano-coating and preparation method thereof

A nano-coating and coating technology, applied in the direction of coating, nano-technology, nano-technology, etc., can solve the problems of low cost, high bonding strength of high-speed steel matrix, difficult to prepare, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0100] The present invention also provides a method for preparing a titanium carbide superhydrophobic nano-ceramic coating compounded on the surface of M2 high-speed steel, comprising the following steps:

[0101] (a) Provide M2 high speed steel, carbon source, titanium source and auxiliary gas;

[0102] (b) Using hydrogen to pretreat the surface of substrates such as M2 high-speed steel; the temperature of the surface pretreatment is 400-450°C.

[0103] (c) Deposit a titanium carbide nanowall on the surface of M2 high-speed steel by chemical vapor deposition method, and the deposition temperature is 940-950°C.

[0104] In another preferred example, the auxiliary gas in step (a) is selected from one or more of the following group: argon, nitrogen, helium, hydrogen, and the auxiliary gas is used as a carrier gas.

[0105] In another preferred embodiment, the auxiliary gas is used to prevent abnormal growth and oxidation of the titanium carbide nanowall structure during the p...

Embodiment 1

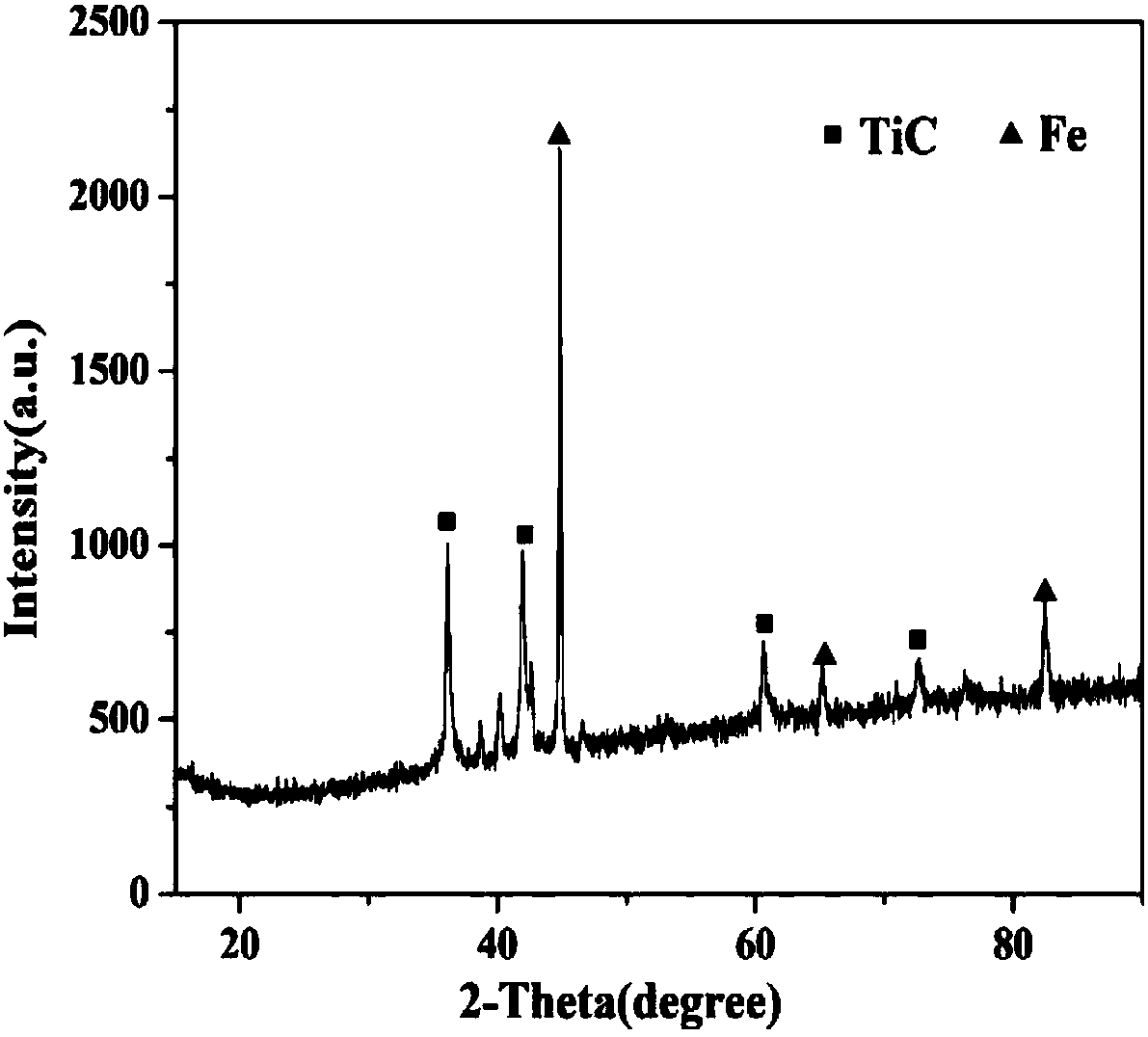

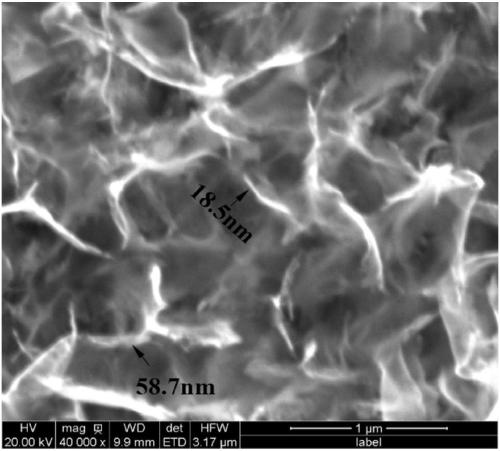

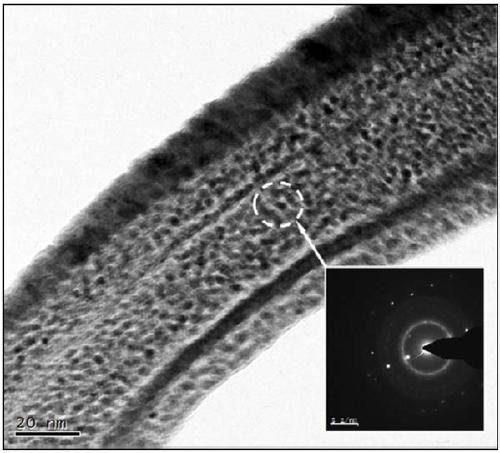

[0124] Example 1 Preparation of titanium carbide superhydrophobic nano-ceramic coating compounded on the surface of M2 high speed steel

[0125] The surface of the M2 high-speed steel with a size of 20mm*20mm*4mm is polished to remove impurities, ultrasonically cleaned with acetone, dried, and placed in a CVD furnace.

[0126] CVD furnace is evacuated to 10 -1 Pa, filled with hydrogen, the gas flow rate is 150cssm. The CVD furnace starts the heating mode, the heating target temperature is 940°C, and the heating rate is 10°C / min. Heat the CVD furnace to 400°C, increase the hydrogen flow rate to 550 sccm, and keep the temperature for 25 minutes.

[0127] The hydrogen flow rate is reduced to 150 sccm, and the CVD furnace continues to heat up to 940°C to enter the heat preservation mode for 25 minutes. At the same time, methane, propylene and titanium tetrachloride are introduced. The carrier gas is loaded into the CVD furnace, and the flow rate of the carrier gas is 2000 sccm....

Embodiment 2

[0158] Embodiment 2 Titanium carbide coating surface water drop contact angle test

[0159] The titanium carbide superhydrophobic nano-ceramic coating that is composited on the M2 high-speed steel surface obtained in Example 1, the titanium carbide crystal coating that is composited on the M2 high-speed steel surface that is obtained in Comparative Example 1, and the composite that is obtained in Comparative Example 2 on M42 high-speed steel The titanium carbide lamellar coating on the surface was tested for contact angle performance comparison.

[0160] Among them, the water droplet contact angle test was carried out on the titanium carbide nanowall compounded on the surface of M2 high speed steel and the titanium carbide crystal coating compounded on the surface of M2 high speed steel. The results are as follows Figure 6A and Figure 6B Shown; The titanium carbide lamellar coating that comparative example 2 obtains is compounded on the surface of M42 high-speed steel carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com