Correction method of concrete cast-in-place pile and construction method of cast-in-place pile on raft foundation

A raft foundation and construction method technology, applied in the direction of foundation structure engineering, building, sheet pile wall, etc., can solve the problems of limiting pile caps to resist horizontal and vertical loads, ground uplift, and difficulty in sinking pipes, etc., to achieve improved pile foundation Bearing capacity, accelerated construction speed, and the effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

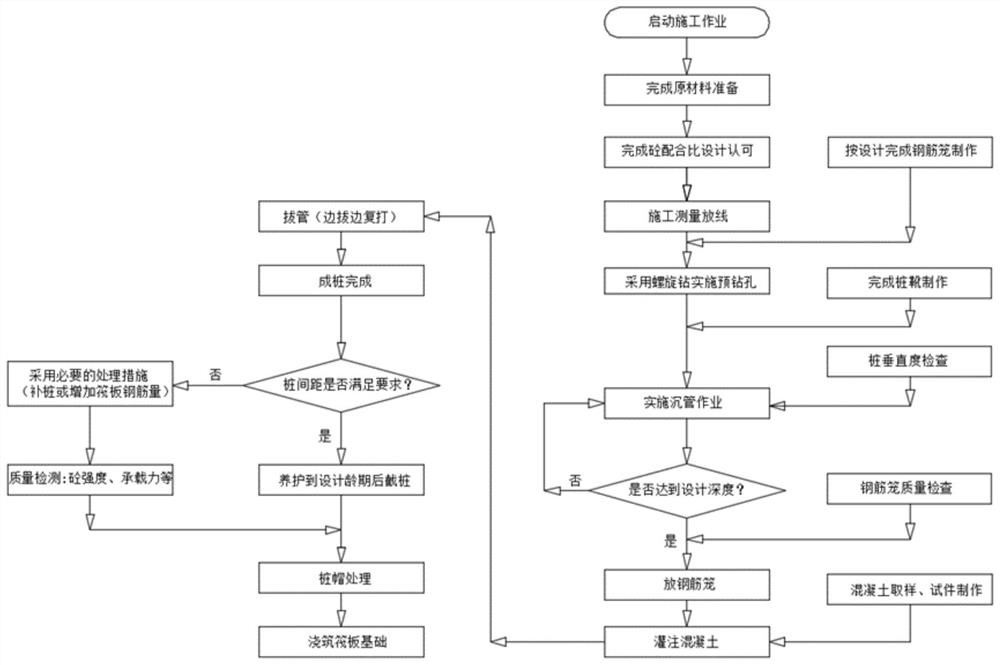

Method used

Image

Examples

Embodiment Construction

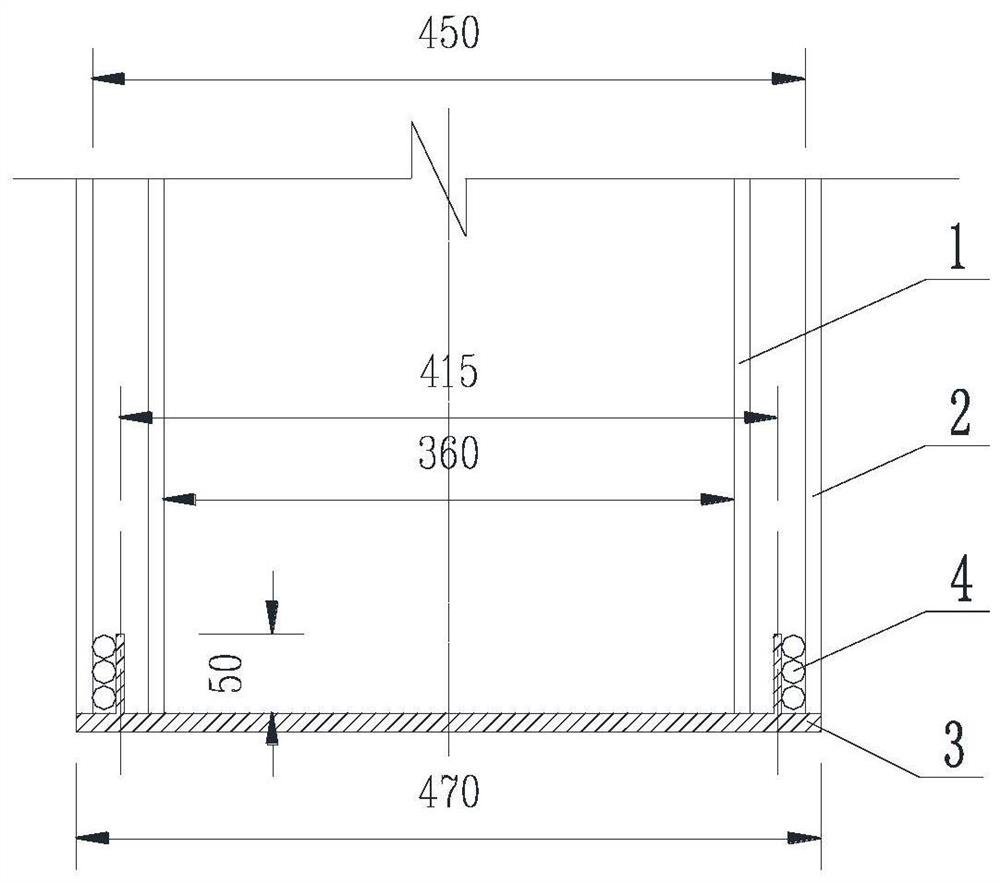

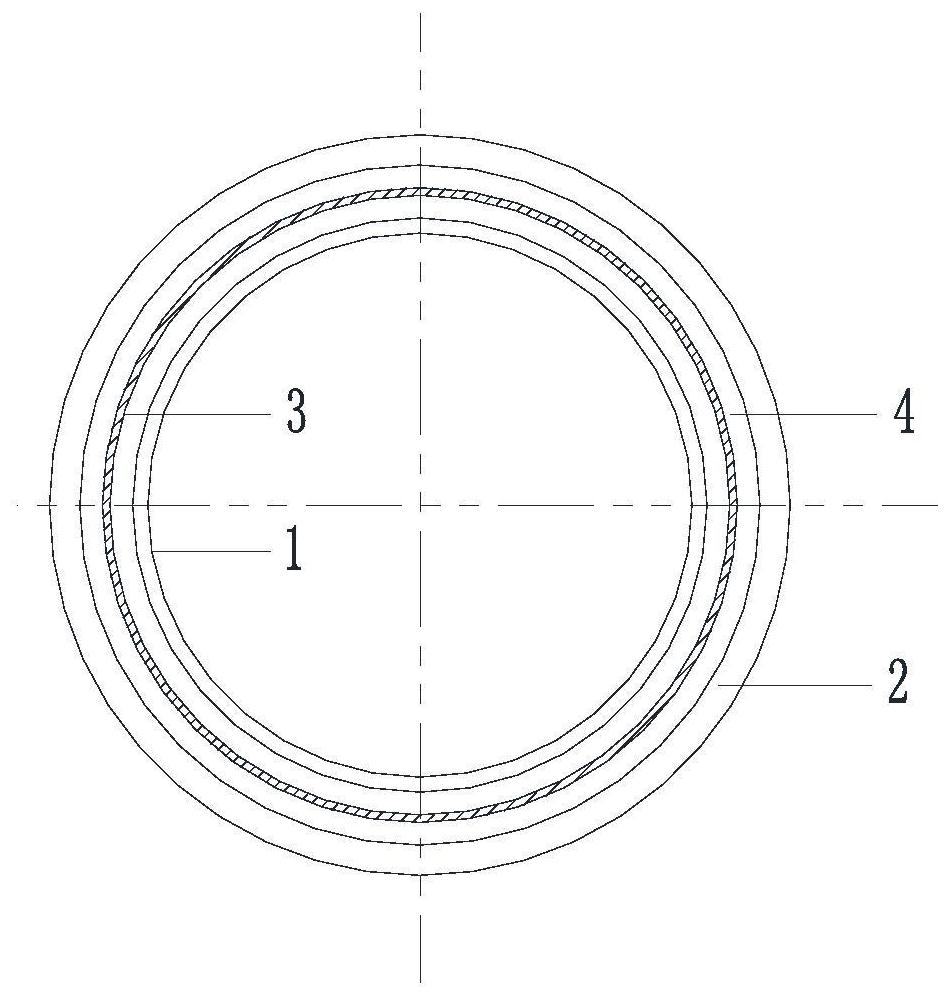

[0031] Correction method for cast-in-place concrete piles: additionally increase the number of steel bars in the raft slab connected to the pile cap of the concrete cast-in-place pile, and the additional steel bars are arranged in both directions above and below the raft slab foundation; the calculation method for the amount of additional steel bars in the raft slab is:

[0032] S1. Mark the design spacing of concrete pouring pile foundations as L, assume the uniform load acting on the raft as q, and simplify the load acting on the raft to a simply supported beam, then the bending force acting on the raft Moment M o for:

[0033] m o =qL 2 / 8 Formula 1-1

[0034] The actual position offset ΔL of the marked concrete pouring pile foundation, if ΔL is greater than the allowable value of the construction acceptance specification, the actual bending moment M acting on the raft d for:

[0035] m d =q(L+ΔL) 2 / 8 formula 1-2

[0036] Due to the excessive construction deviation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com