Using method for movable riverway sludge dredging device

A mobile, river technology, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of changing draft depth, unstable equipment center, and unsuitable dredging devices for large rivers and other problems to achieve the effect of avoiding motor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

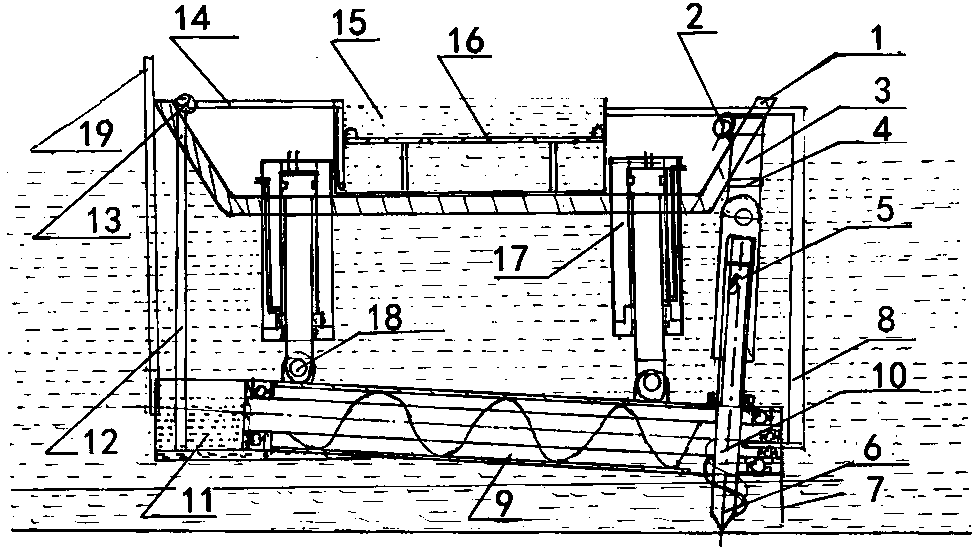

[0041] Embodiment 1, with reference to attached figure 1 , a mobile river sludge dredging device mentioned in the present invention includes a movable hull 1 and a sludge dredging device, and the sludge dredging device includes a power machine 2, a transmission connecting shaft 3, a universal joint 4, a spline shaft 5. Silt agitator 6, water circulation pipe 8, double-capacity mixer 9, turbine drive 10, sewage storage tank 11, sewage siphon 12, sewage pump 13, sewage pump outlet pipe 14, sludge treatment tank 15, multi-stage pollution reduction device 16, lifting hydraulic cylinder 17, adjustment shaft 18, the power machine 2 is installed at the bow of the movable hull 1, connected to the spline sleeve through the transmission connection shaft 3 and the universal joint 4, and the spline sleeve is movably connected to the spline sleeve. The key shaft 5, the lower end of the spline shaft 5 is connected to the mud agitator 6, and the mud agitator 6 provides power to the double-ca...

Embodiment 2

[0064] Embodiment 2, the technical scheme mentioned in the present invention is compared with embodiment 1, and difference is:

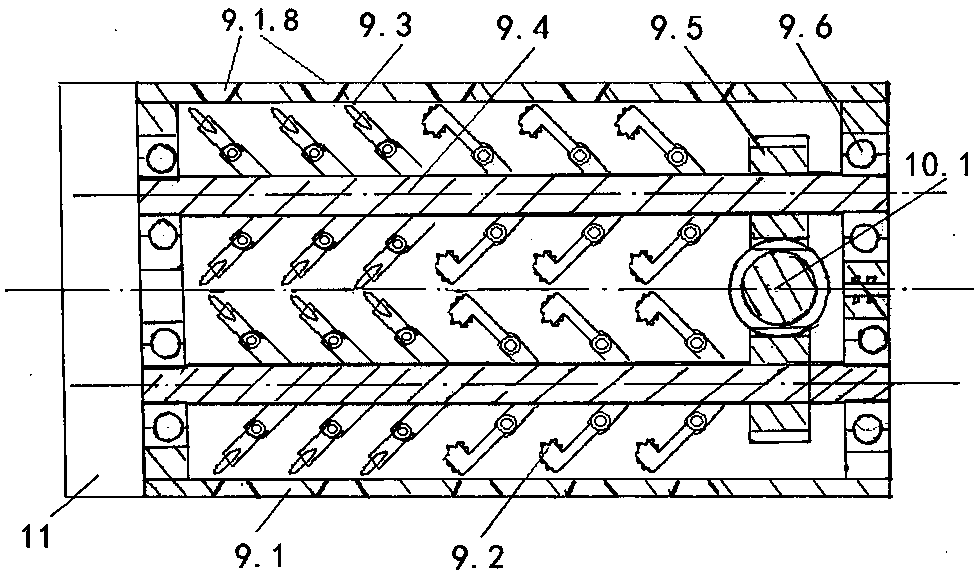

[0065] Refer to attached Figure 10 The conveying plummet 9.2 mentioned in the present invention includes a plummet head 9.2.1, a plummet rod 9.2.2, a side plummet sawtooth 9.2.3, and a main plummet sawtooth 9.2.4. The plummet rod 9.2.2 The lower end is provided with a pin hole, and the upper end is provided with a pendent head 9.2.1 front and rear. The front end of the pendent head 9.2.1 is provided with a main pendent saw tooth 9.2.4, and the outer wall is evenly provided with a side pendent saw tooth 9.2.3. The conveying hammers with hammerheads at the front and rear, and the sawtooth structure can hammer the stones more evenly, and its crushing effect is better than that of a single head; in addition, the side suspension hammer provided by the present invention Hammer sawtooth 9.2.3 and main plummet sawtooth 9.2.4 can be made of diamond material...

Embodiment 3

[0066] Embodiment 3, the technical scheme that the present invention mentions compares with embodiment 1 and 2, and difference is:

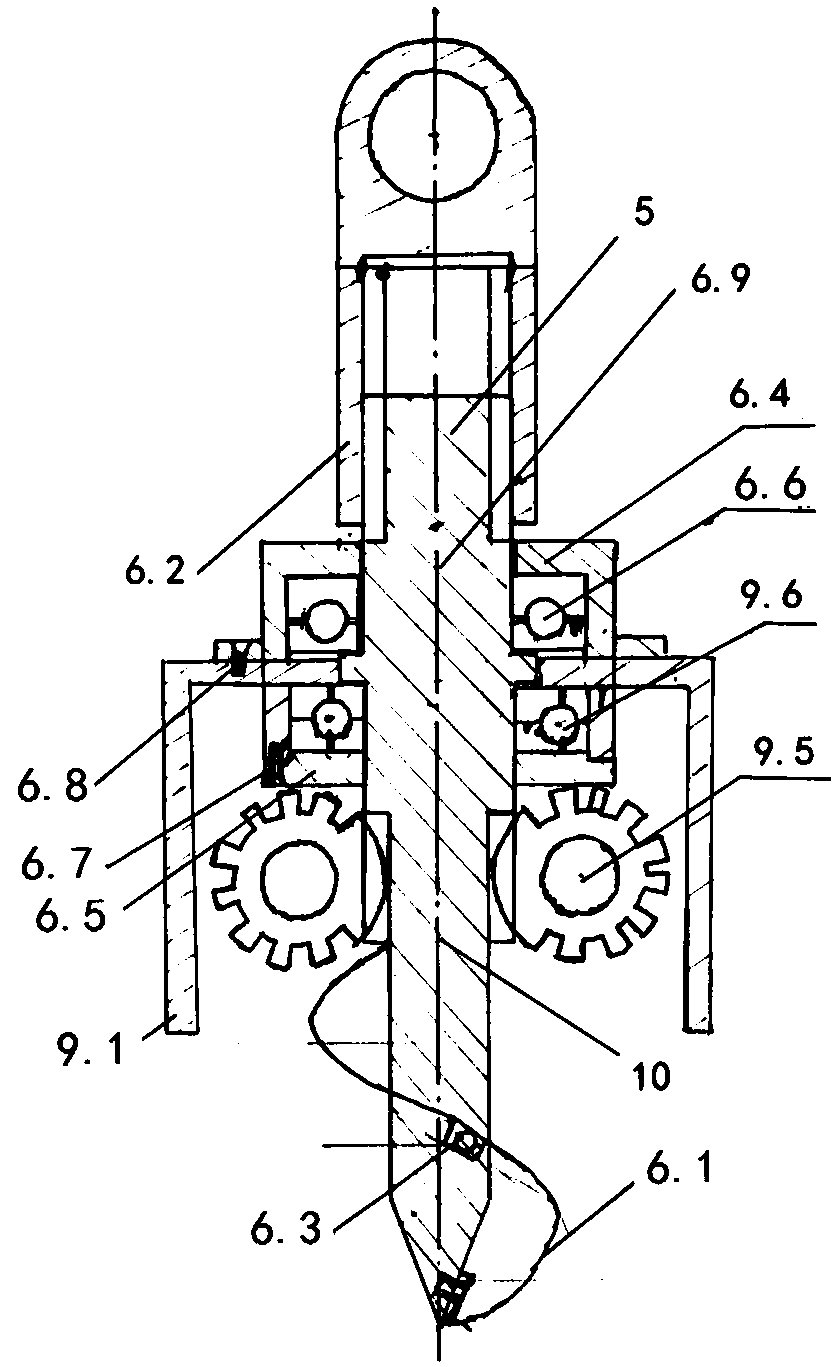

[0067] Refer to attached Figure 11 , The sludge agitator 6 of the present invention comprises stirring suspension blade 6.1, spline sleeve 6.2, suspension blade fixing bolt 6.3, pressure bearing pressure cap 6.4, rolling bearing pressure cap 6.5, pressure bearing 6.6, lower pressure cap bolt 6.7, upper pressure cap bolt 6.8. Agitating main shaft 6.9, the upper end of said agitating main shaft 6.9 is connected with spline shaft 5 and spline sleeve 6.2, and the upper middle part of agitating main shaft 6.9 is connected with double-capacity mixer housing 9.1 through rolling bearing pressure cap 6.5 and pressure bearing 6.6, The lower side of the middle part of the agitating main shaft 6.9 engages the transmission gear 9.5 through the turbine driver 10, and the lower end of the agitating main shaft 6.9 is connected to the agitating suspension blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com