Condensing type gas-fired boiler heat exchanger, alloy for heat exchanger and boiler

A gas-fired boiler and heat exchanger technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problem of poor elongation and impact resistance, unretrieved heat exchanger Impact ability, reducing corrosion depth and other issues, to achieve enhanced heat absorption effect, efficient absorption of flue gas latent heat, and enhanced full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

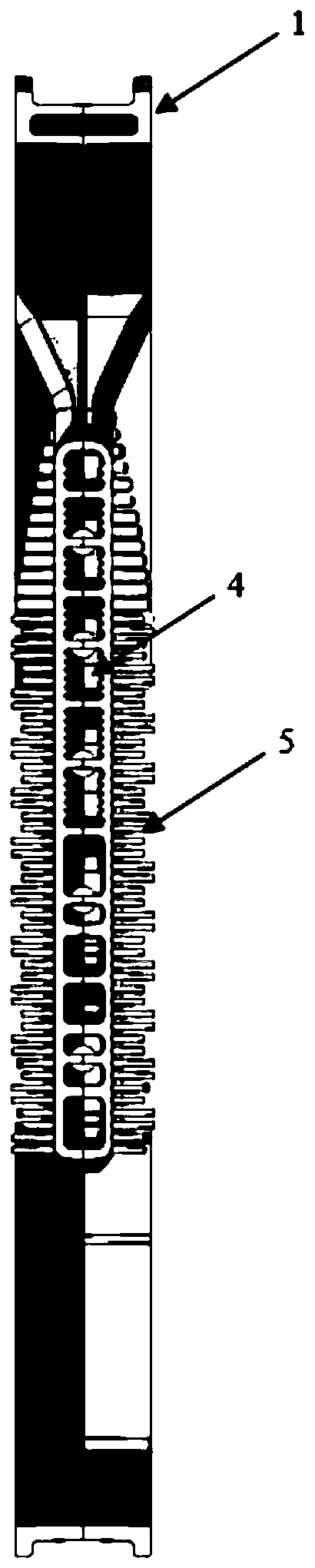

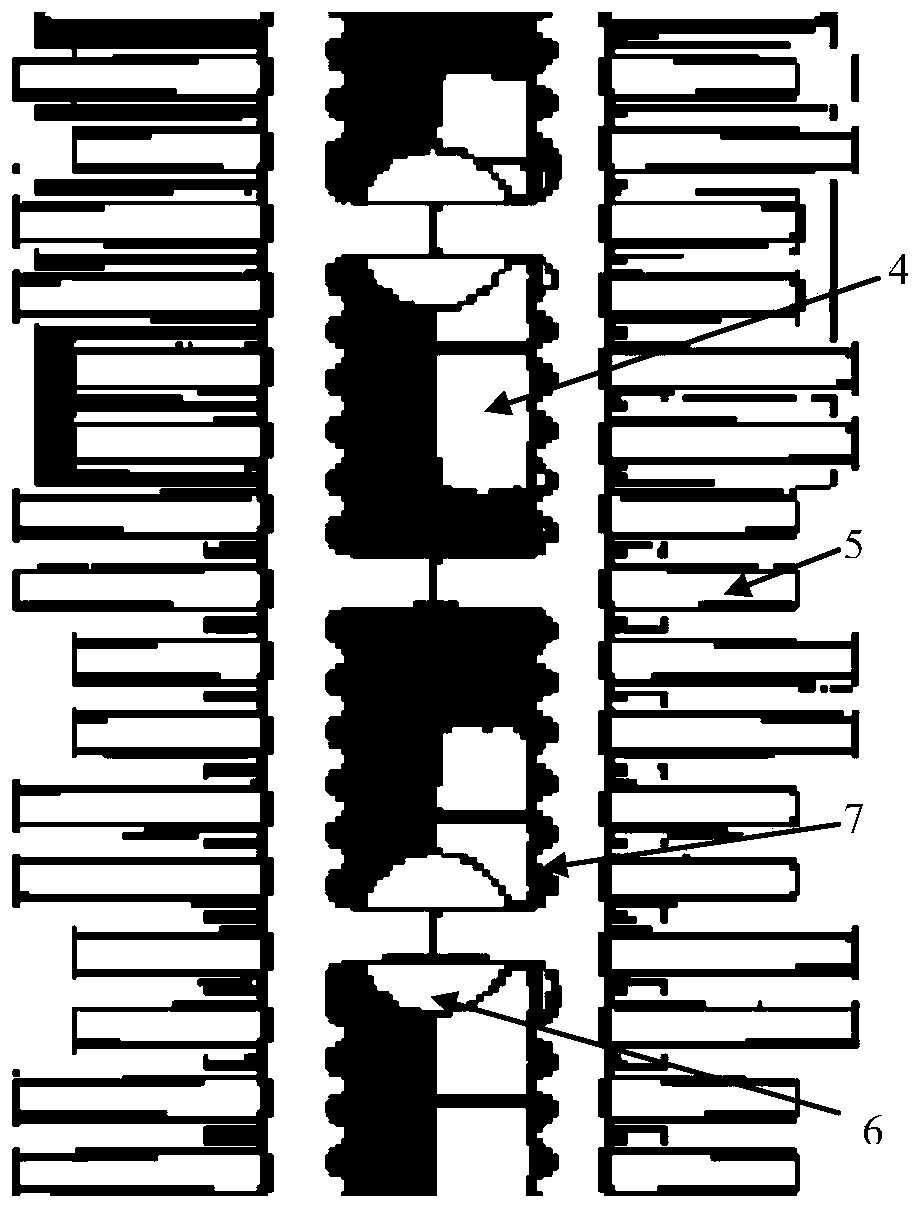

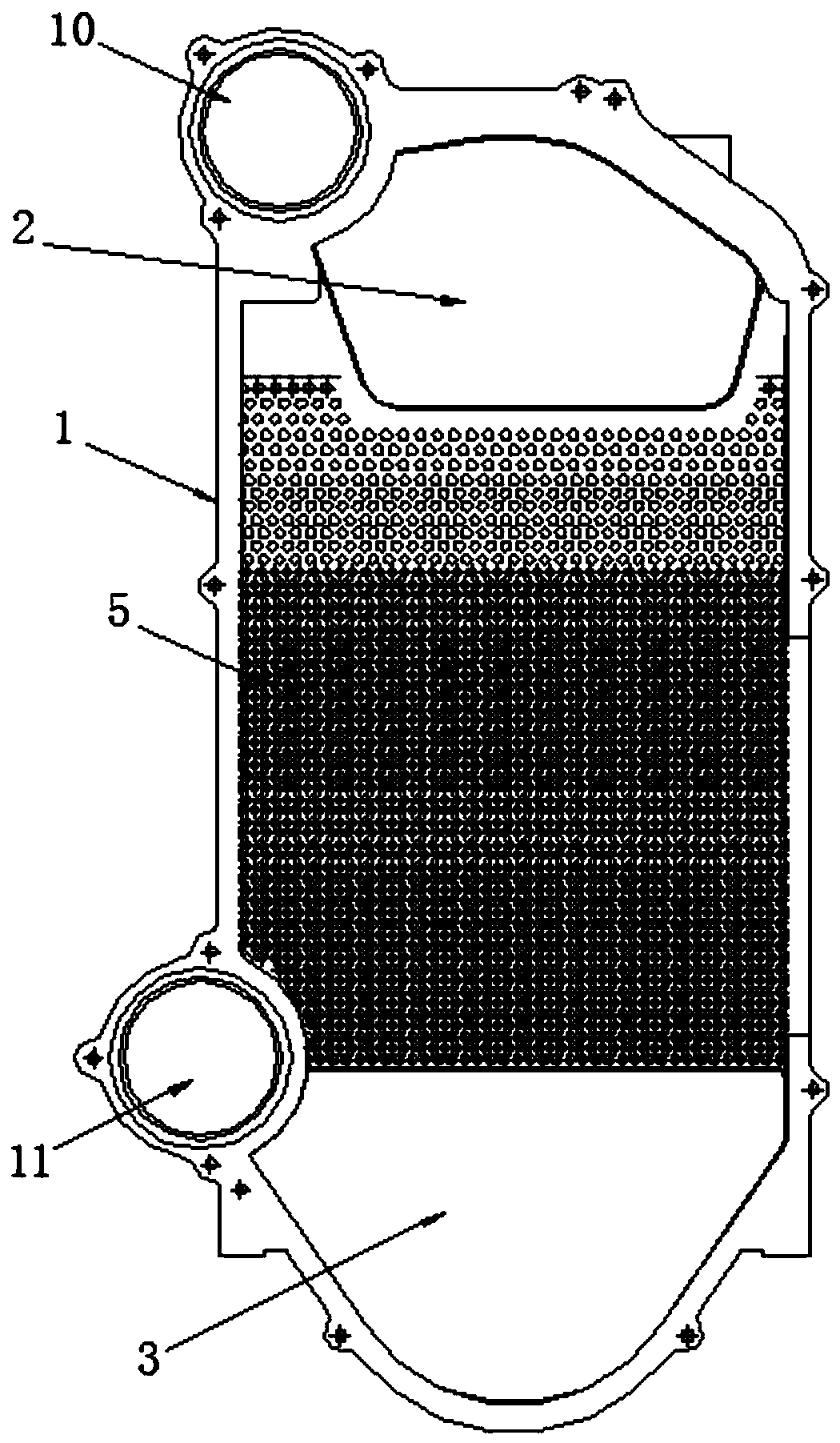

[0036] like Figure 1 to Figure 5 as shown ( Figure 4 The so-called longitudinal section refers to Figure 4 Yes figure 1 along figure 1 The view after the longitudinal section of the middle part), the present invention is a condensing gas boiler heat exchanger, including a heat exchanger body 1, a combustion chamber 2 and a smoke exhaust chamber 3 connected to each other are arranged in the body, and the combustion chamber 2 and the exhaust chamber are arranged in the body. Condensation water channels 4 are arranged between the smoke chambers 3, and the condensation water channels 4 are integrated with the body; the outer surface of the condensation water channels 4 is integrally provided with heat dissipation protrusions 5, and the closer the condensation water channels 4 are to the combustion chamber 2, the denser they are arranged. A heat exchange enhancement column 6 is fixedly installed in the condensation channel 4, and both ends of the heat exchange enhancement col...

Embodiment 2

[0071] The difference from Example 1 is that the alloy for the heat exchanger of the condensing gas boiler contains the following components in weight percentage: silicon: 9.5%, magnesium: 0.30%, iron: 0.13%, titanium: 0.11%, strontium: 0.02%, The balance is aluminum.

Embodiment 3

[0073] The difference from Example 1 is that the alloy for the heat exchanger of the condensing gas boiler contains the following components in weight percentage: silicon: 9%, magnesium: 0.29%, iron: 0.13%, titanium: 0.10%, strontium: 0.02%, The balance is aluminum.

[0074] With reference to GB T 6892-2006 general industrial aluminum and aluminum alloy extruded profiles, the heat exchangers made in the above three embodiments were tested, and the results are as follows:

[0075]

[0076] The relationship between the amount of magnesium added and the tensile strength and elongation at break, such as Image 6 Shown (remaining element content is the proportioning content of embodiment one), the addition of Mg element can form Mg 2 Si dispersion strengthening phase improves the mechanical properties of the alloy; however, the choice of Mg content needs to balance the inverse relationship between strength and elongation, and the Mg content is selected to be 0.25% to 0.35%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com