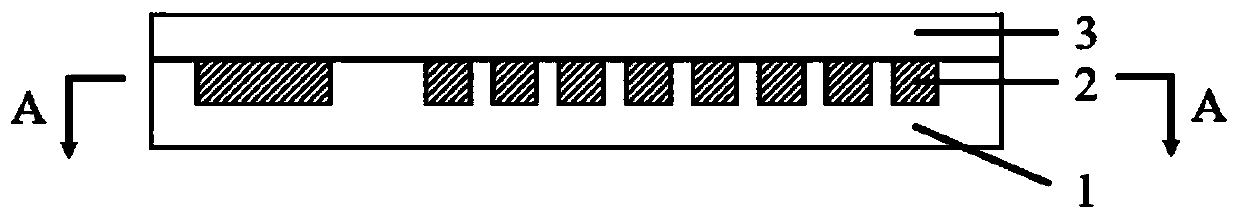

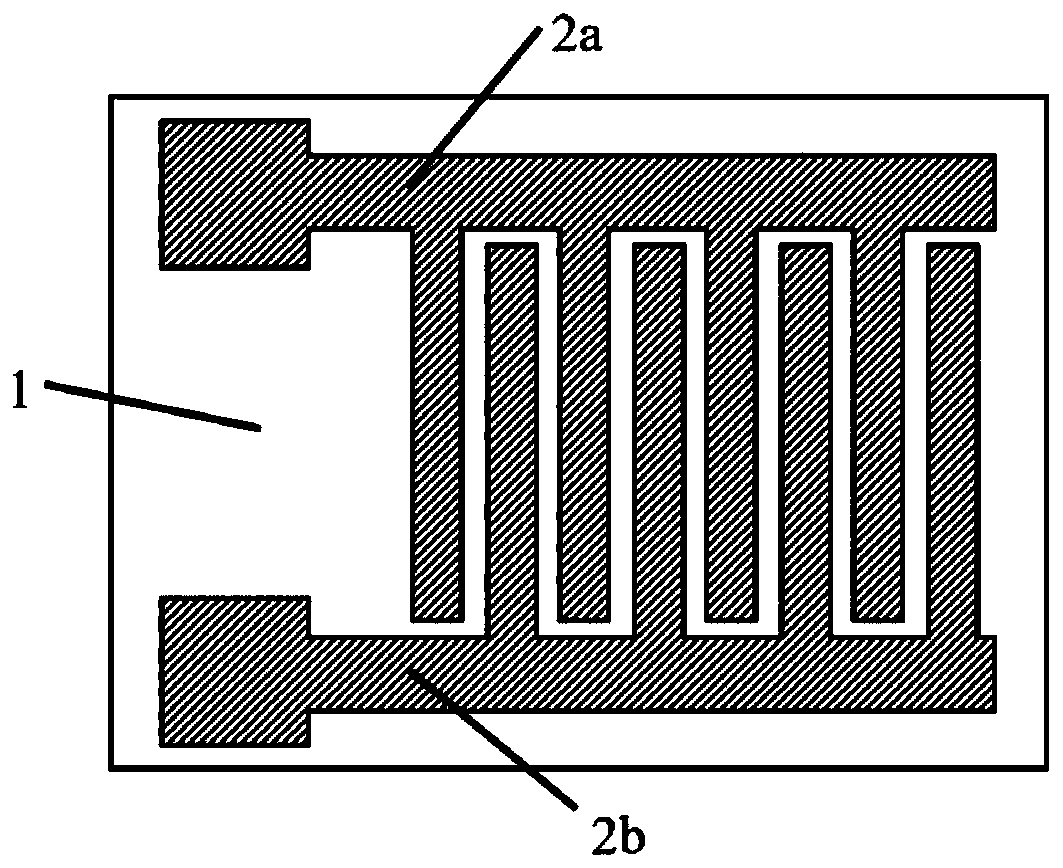

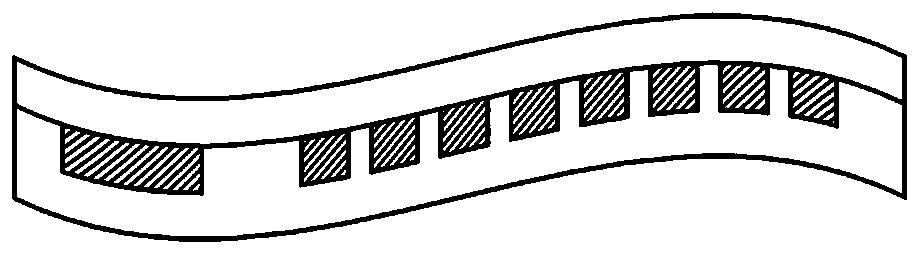

Self-repairing micro super capacitor and preparation method thereof

A supercapacitor, self-healing technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve problems such as volume increase and leakage, and achieve excellent printing performance, excellent repair performance, The effect of self-healing efficiency at room temperature with high electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) The 2-acrylamide-2-methyl-1-propanesulfonic acid (AMPSA) of 1.88g is dissolved in the PVA-124 aqueous solution that the mass fraction of 2g is 6wt%, use magnetic stirring (300-400 rev / Minutes) After completely dissolving, add photoinitiator 2959 (2-hydroxyl-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone) 4mg, N,N'-dimethyl Base bisacrylamide (MBAA) 8mg, lithium chloride 85mg mixed and stirred until completely and uniformly dissolved.

[0057] (2) 2g concentration of 0.15wt% PEDOT:PSS aqueous solution, 300mg concentration of 1wt% sodium carboxymethyl cellulose viscosifier was added to the small glass bottle, stirred vigorously at room temperature, then added 120mg concentration of 50wt % lithium bis(trifluoromethanesulfonyl)imide (LiTFSI) aqueous solution was stirred continuously to make it evenly mixed. Then the above viscous mixture was reacted in an oven at 90° C. for 5 hours. Transfer the self-assembled PEDOT:PSS hydrogel into a syringe for later use.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com