Cobalt-based Fischer-Tropsch synthesis catalyst and preparation method thereof

A Fischer-Tropsch synthesis and catalyst technology, which is used in catalyst activation/preparation, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the problem of catalyst activity and stability decline, active cobalt species prone to sintering, and hydrothermal stability. Deterioration and other problems, to achieve the effect of good hydrothermal stability, good anti-sintering ability, good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A second aspect of the present invention provides a method for preparing a cobalt-based Fischer-Tropsch synthesis catalyst, wherein the method includes:

[0040] (1) The carrier is immersed in an equal volume of the first impregnation solution for the first impregnation, and then dried to obtain a catalyst intermediate, wherein the carrier is ZnO and TiO 2 and / or ZrO 2 Modified Al 2 O 3 carrier;

[0041] (2) the catalyst intermediate is impregnated in the second impregnating liquid with equal volume for the second impregnation, and then drying and roasting are carried out;

[0042] Wherein, the first immersion liquid is a solution containing soluble cobalt salt and a first auxiliary agent precursor, and the second immersion liquid is a solution containing soluble cobalt salt and a second auxiliary agent precursor.

[0043] According to the preparation method of the present invention, the dosage ratio of the carrier, the active component, and the first adjuvant and t...

Embodiment 1

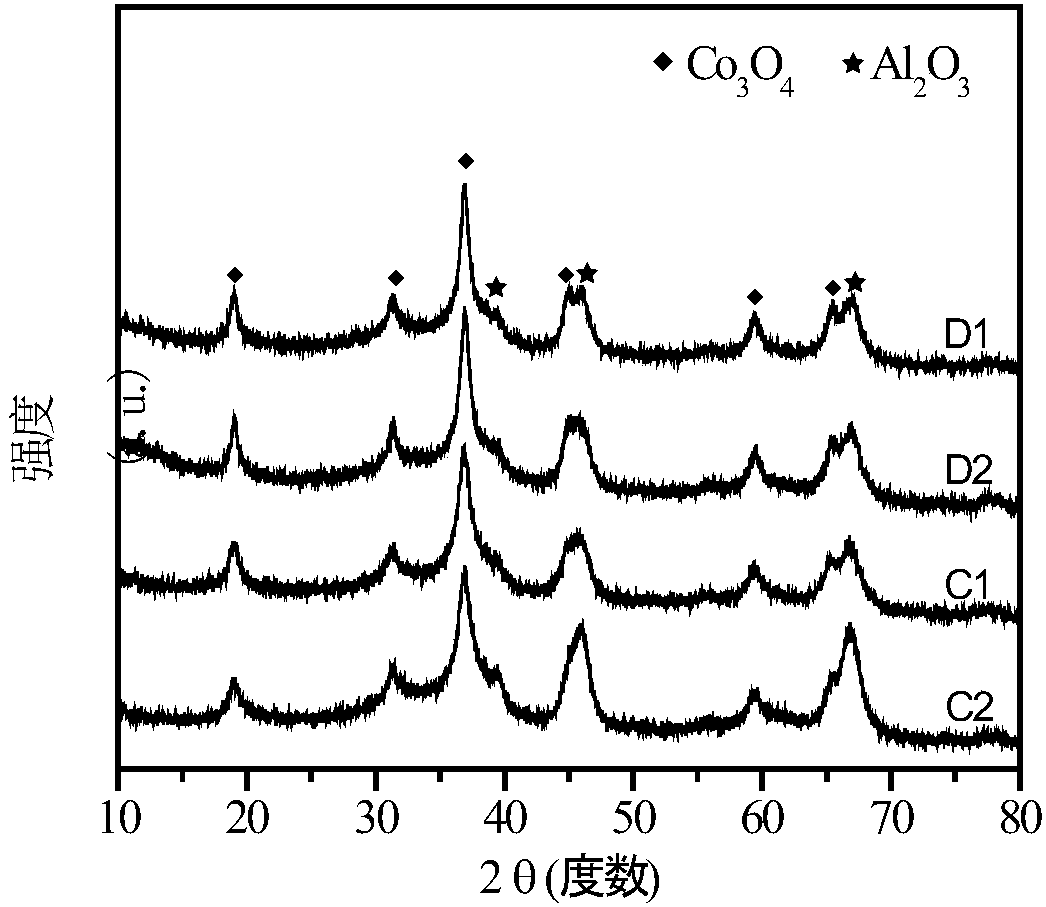

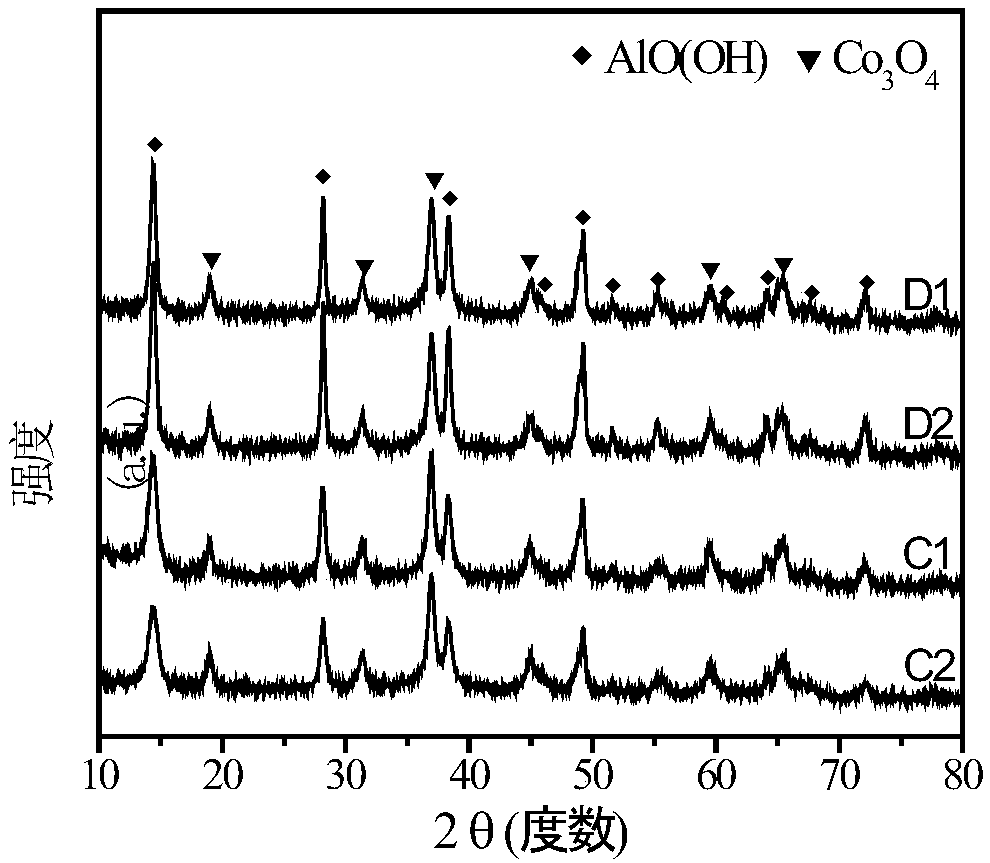

[0066] This example is to illustrate the cobalt-based Fischer-Tropsch synthesis catalyst prepared by the preparation method of the present invention.

[0067] Step (1): Preparation of Carrier

[0068] Based on 500g pseudo-boehmite, according to the TiO in the carrier 2 , ZnO, Al 2 O 3 The weight ratio of the dosage is 6.5:2.2:100. Calculate and weigh the corresponding tetrabutyl titanate and the corresponding Zn(NO 3 ) 2 ·6H 2 O;

[0069] Tetrabutyl titanate, Zn(NO 3 ) 2 ·6H 2 O was mixed with pseudo-boehmite, 50 mL of dilute nitric acid with a concentration of 5% and 300 mL of deionized water, kneaded evenly and extruded into strips, then dried at 120 °C for 10 hours, and then calcined at 450 °C for 5 hours. get labeled TiO 2 -ZnO-Al 2 O 3 -1 carrier; and the carrier has a specific surface area of 157.7m 2 / g, the pore volume is 0.58cm 3 / g, the average pore diameter is 10.5 nm.

[0070] Step (2): Preparation of cobalt-based Fischer-Tropsch synthesis catalyst...

Embodiment 2

[0075] This example is to illustrate the cobalt-based Fischer-Tropsch synthesis catalyst prepared by the preparation method of the present invention.

[0076] Step (1): Preparation of Carrier

[0077] Based on 500g pseudo-boehmite, according to the TiO in the carrier 2 , ZnO, Al 2 O 3 The weight ratio of the dosage is 4.2:2.1:100 to calculate and weigh the corresponding tetrabutyl titanate and the corresponding Zn(NO 3 ) 2 ·6H 2 O;

[0078] Tetrabutyl titanate, Zn(NO 3 ) 2 ·6H 2 O was mixed with pseudo-boehmite, 50 mL of dilute nitric acid with a concentration of 5% and 300 mL of deionized water, kneaded evenly and extruded into strips, then dried at 120 °C for 10 hours, and then calcined at 500 °C for 5 hours. get labeled TiO 2 -ZnO-Al 2 O 3 -2 carrier; and the carrier has a specific surface area of 166.2m 2 / g, the pore volume is 0.61cm 3 / g, the average pore diameter is 9.5 nm.

[0079] Step (2): Preparation of cobalt-based Fischer-Tropsch synthesis catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com