Mold and method for preparing ceramic matrix composite coil spring of SiC fiber

A helical spring and composite material technology, which is applied in the field of ceramic matrix composite helical spring molds, can solve the problems of poor reliability and short life, and achieve the effects of high molding efficiency, high molding precision, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

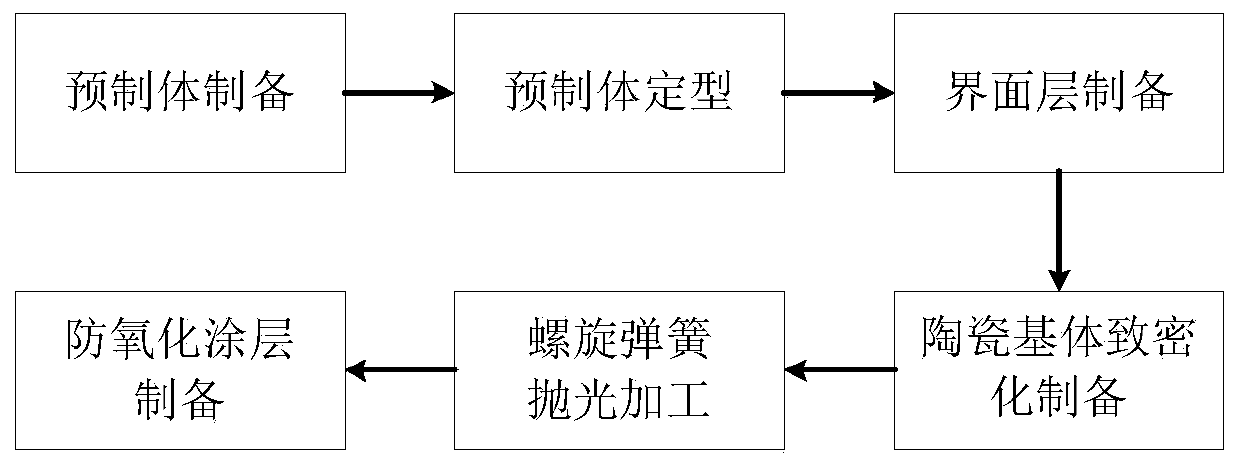

[0032] The technical scheme adopted by the present invention to solve its technical problems: a method for preparing a ceramic matrix composite coil spring based on SiC fibers, which is characterized in that it includes the following steps:

[0033] Step 1, quasi-one-dimensional fiber rope parameter design. According to the spring specifications, determine the diameter of the fiber rope, based on this to design and determine the number of SiC fiber bundles.

[0034] Step 2: Prepare a round tube mold, and the diameter of the round tube refers to the size specification of the coil spring. Holes are made on the surface of the circular tube mold as a guide channel for the deposition gas of the ceramic matrix, and the mold material is made of high-temperature resistant graphite material.

[0035] Step 3: Wrap the quasi-one-dimensional fiber rope in the spiral groove of the high-temperature mold and fix it to complete the shaping of the coil spring.

[0036] Step 4, preparing a BN...

Embodiment 1

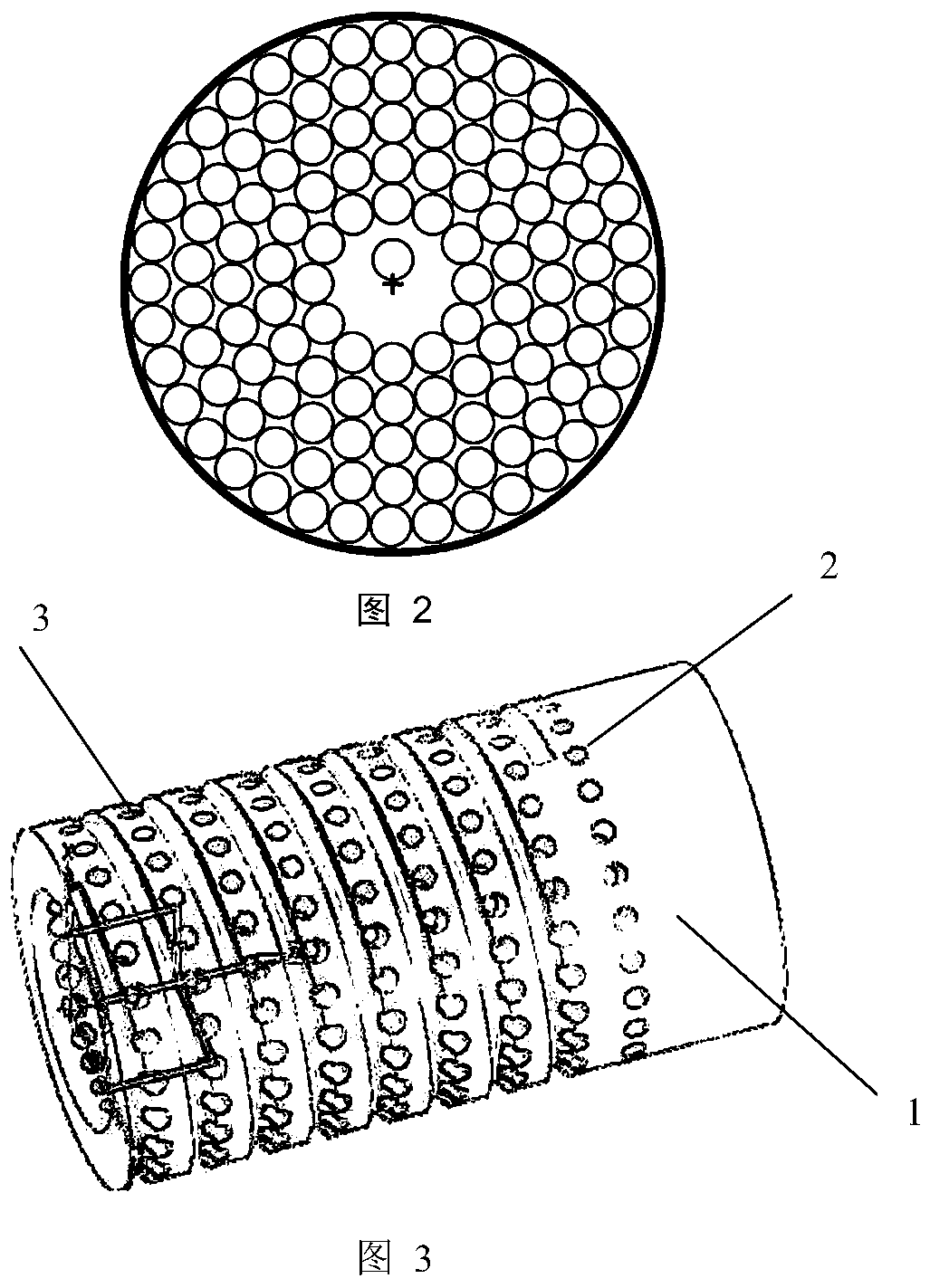

[0043] (1) Prepare a quasi-one-dimensional fiber rope with a diameter of 2 mm.

[0044] (2) Prepare a circular tube-shaped high-temperature mold with a diameter of 30 mm, and wrap the fiber rope in the spiral groove on the surface of the mold to complete the preparation of the coil spring preform.

[0045] (3) Place the prefabricated blank in the CVI deposition furnace, keep a vacuum of 10-3Pa, deposit a BN interface layer on the surface of the SiC fiber, NH3 is used as a nitrogen source, BCl3 provides a boron source, H2 is a dilution gas, NH3, The volume flows of BCl3 and H2 are 500ml / min, 1000ml / min and 2000ml / min respectively, the deposition temperature is 1200℃, the deposition time is 20h, and the thickness of deposited BN is 50μm.

[0046] (4) Place the prefabricated body prepared in step (3) in the CVI deposition furnace, keep the gas pressure in the deposition furnace at 10-2Pa, and start the densification preparation of the SiC matrix. The deposition temperature is 11...

Embodiment 2

[0052] (1) Prepare a quasi-one-dimensional fiber rope with a diameter of 0.7mm.

[0053] (2) Prepare a circular tube-shaped high-temperature mold with a diameter of 20 mm, and wrap the fiber rope in the spiral groove on the surface of the mold to complete the preparation of the coil spring preform.

[0054] (3) Place the prefabricated blank in the CVI deposition furnace, keep a vacuum of 10-3Pa, deposit a BN interface layer on the surface of the SiC fiber, NH3 is used as a nitrogen source, BCl3 provides a boron source, H2 is a dilution gas, NH3, The volume flows of BCl3 and H2 are 500ml / min, 1000ml / min and 2000ml / min respectively, the deposition temperature is 1100℃, the deposition time is 30h, and the thickness of deposited BN is 80μm.

[0055] (4) Place the prefabricated body prepared in step (3) in the CVI deposition furnace, keep the gas pressure in the deposition furnace at 10-2Pa, and start the densification preparation of the SiC matrix. The deposition temperature is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com