Eutectic complex composed of resveratrol and protein kinase inhibitor, and composition comprising eutectic complex

A protein kinase inhibitor, resveratrol technology, applied in the field of medicine, can solve the problem of no resveratrol and protein kinase inhibitor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

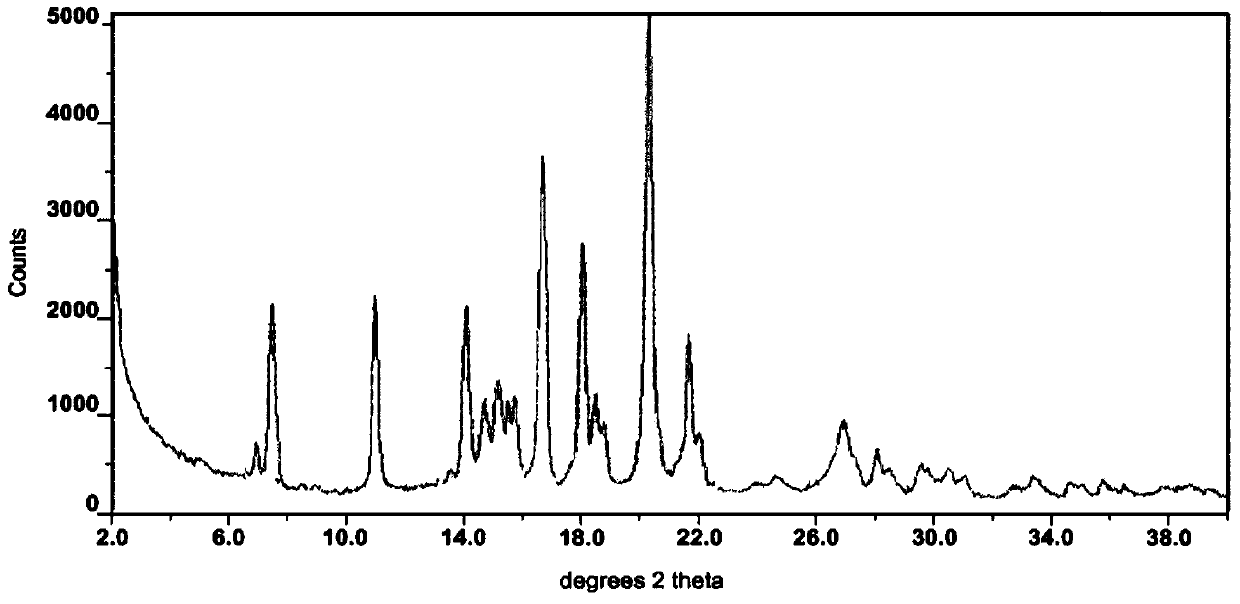

[0096] 1 Preparation of eutectic composite

[0097] The invention adopts the hot-melt extrusion method to prepare the resveratrol-protein kinase inhibitor eutectic complex. Specifically, resveratrol and protein kinase inhibitors in a specific molar ratio are sieved and mixed to form a physical mixture. The screw of the hot-melt extruder (ZE-16 twin-screw hot-melt extruder, ATS Industrial Systems Co., Ltd.) is divided into modules 1~6 (Zone 1~6) from left (feed port) to right, representing 6 There are three temperature zones that can be set, and the process of feeding, conveying, melting and mixing, and output is performed in sequence. The temperature value of each module is set according to the process needs. After the temperature is stable for 10 minutes, the physical mixture is slowly added to the extruder, and the extruder is extruded. The material was ground and pulverized through an 80-mesh sieve, recrystallized, dried, and stored in the dark.

[0098] In the present in...

Embodiment 1

[0119] Example 1 Preparation of resveratrol imatinib co-crystal complex

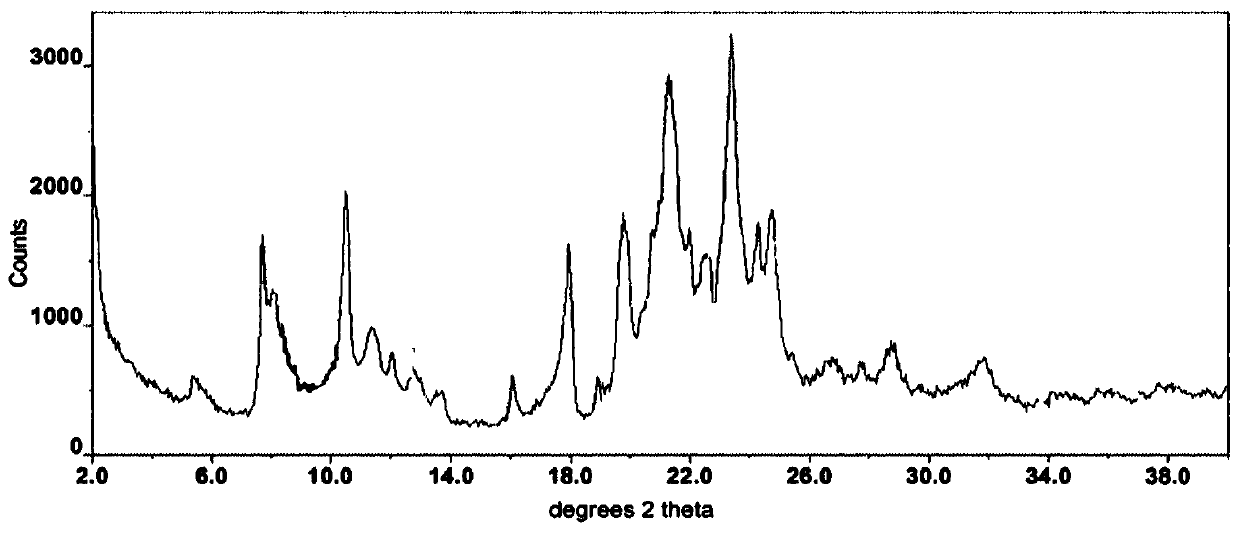

[0120] Take resveratrol 493.6g and imatinib 100g, sieve and mix, as a physical mixture. The screw of the hot-melt extruder (ZE-16 twin-screw hot-melt extruder, ATS Industrial Systems Co., Ltd.) is divided into modules 1~6 from left (feeding port) to right, Zone 1~6) represents 6 There are three adjustable temperature zones, and the processes of feeding, conveying, melting and mixing, and output are performed in sequence. The temperature of modules 1-6 is 155°C, 175°C, 195°C, 225°C, 260°C, 165.8-167.6°C in sequence, and the rotation speed is 10r / min. After the temperature stabilizes for 10min, feed at a speed of 3g / min. The extrudate was collected, ground and passed through an 80-mesh sieve to obtain 999.175 g of an off-white solid with a melting point of 180.1-181.3°C. Recrystallize with ethanol, and dry to obtain 998.725 g of white solid, melting point is 211-211.1 °C, R value is 0.319, and its X-ray ...

Embodiment 2

[0121] Example 2 Preparation of resveratrol·erlotinib co-crystal complex

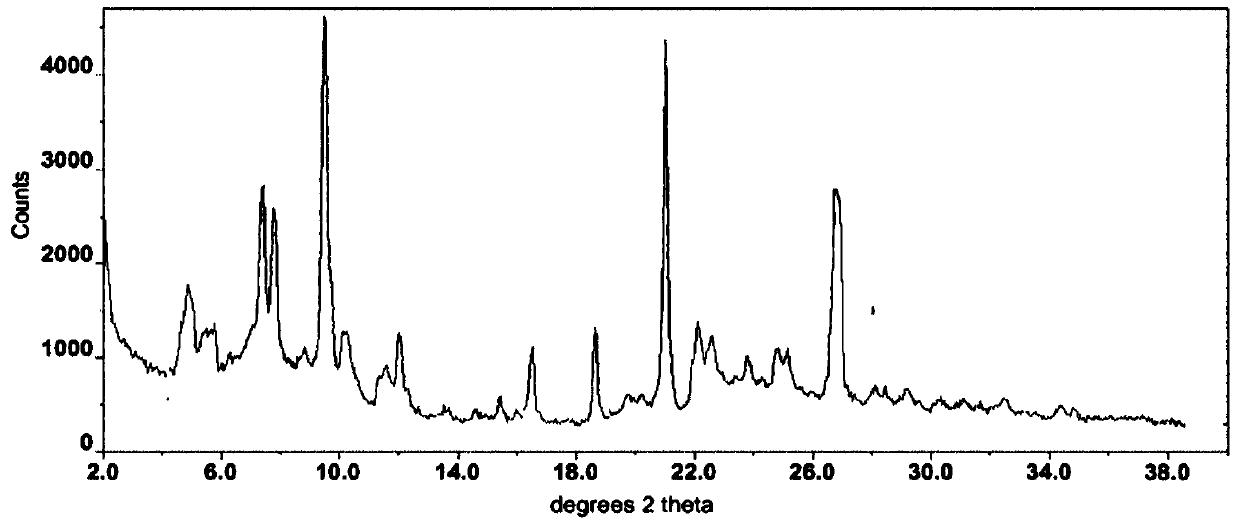

[0122] Take resveratrol 393.44g and erlotinib 100g, sieve and mix, as a physical mixture. The screw of the hot-melt extruder (ZE-16 twin-screw hot-melt extruder, ATS Industrial Systems Co., Ltd.) is divided into modules 1~6 from left (feeding port) to right, Zone 1~6) represents 6 There are three adjustable temperature zones, and the processes of feeding, conveying, melting and mixing, and output are performed in sequence. The temperature of modules 1 to 6 is 125°C, 180°C, 185°C, 235°C, 260°C, 180.4 to 181.6°C in sequence, and the rotation speed is 10r / min. After the temperature stabilizes for 10min, feed at a speed of 3g / min. The extrudate was collected, ground and passed through an 81-mesh sieve to obtain 999.369 g of an off-white solid with a melting point of 190.3-191.3°C. Recrystallize with isopropanol and dry to obtain 998.677g of white solid, melting point is 163.8~164.7°C, R value is 0.513, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com