Compound with mesitylene as core, preparation method thereof, and application of compound in organic light-emitting device

A compound, toluene technology, applied in the application field of organic electroluminescent devices, can solve problems such as performance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

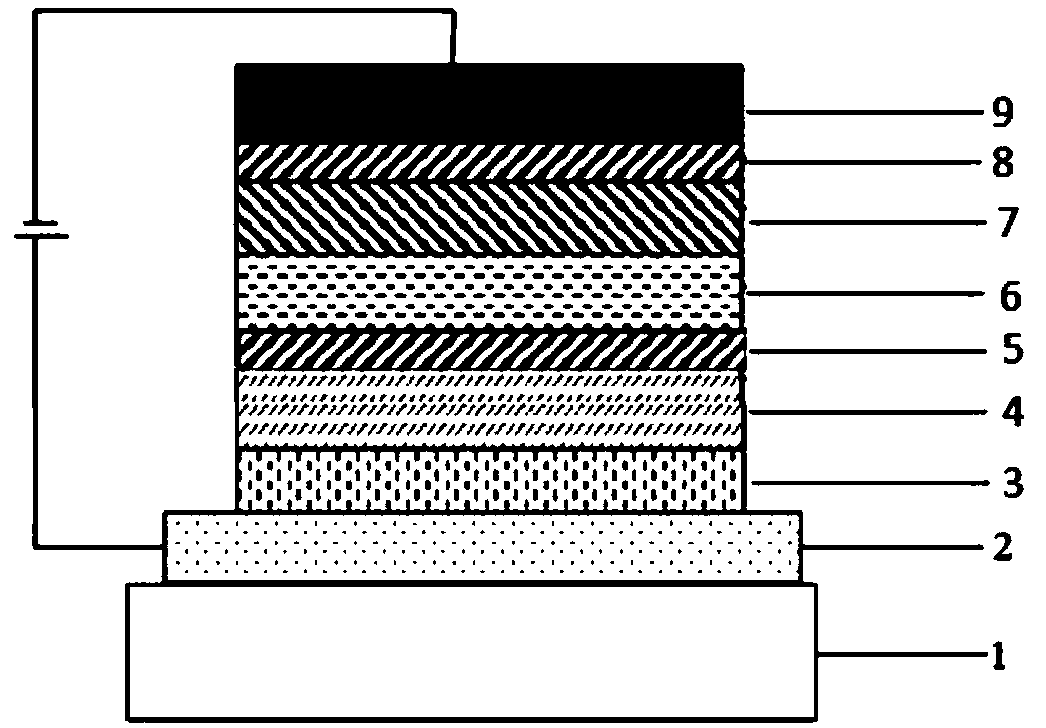

Image

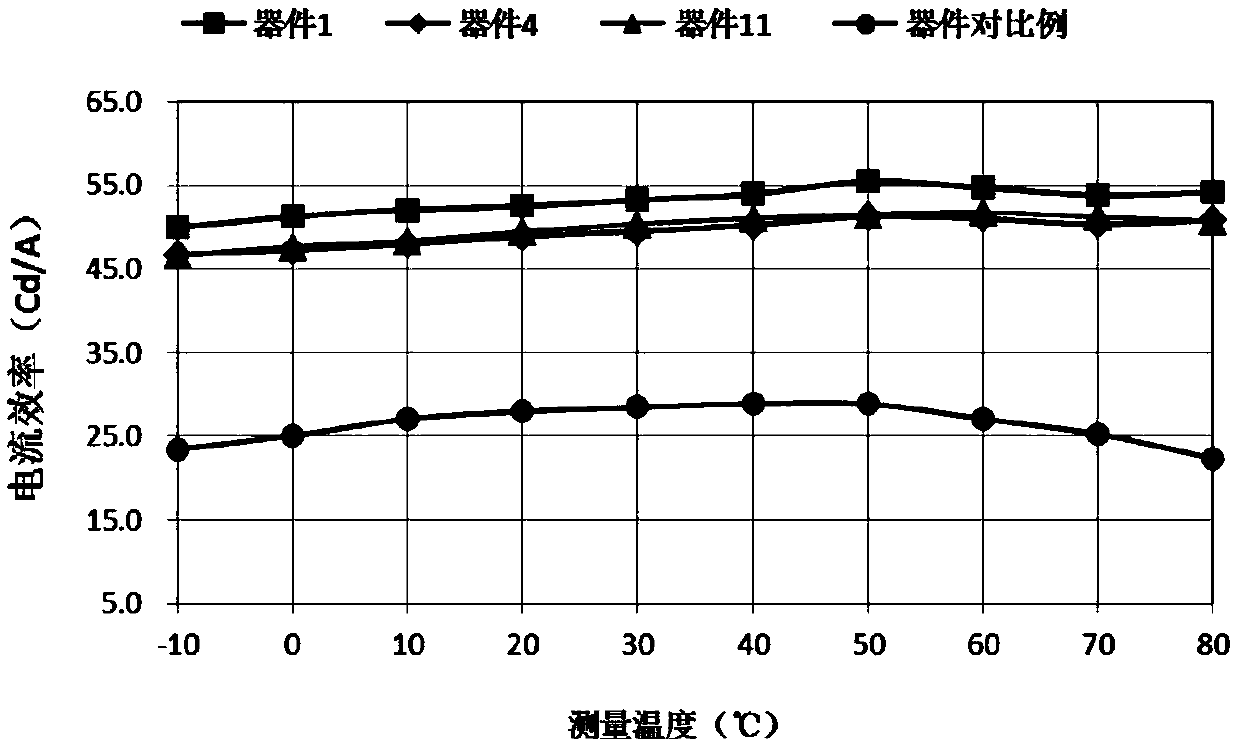

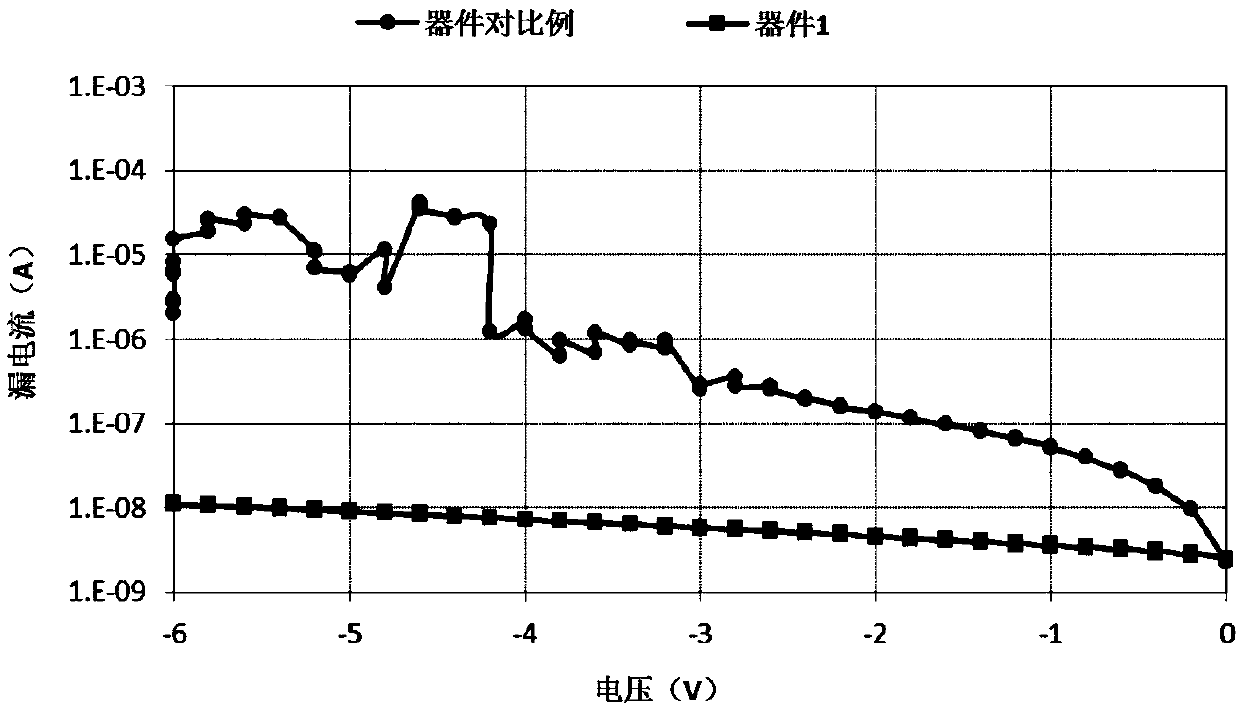

Examples

Embodiment 1

[0071] The preparation of embodiment 1 intermediate

Embodiment 1-1

[0072] The preparation of embodiment 1-1 intermediate N

[0073]

[0074] Dissolve raw material I and raw material II in toluene, add Pd 2 (dba) 3 , triphenylphosphine and potassium tert-butoxide; under an inert atmosphere, react the mixed solution of the above reactants at a temperature of 90-110°C for 10-24 hours, cool and filter the reaction solution, spin the filtrate, and pass the residue through silica gel Column, obtain intermediate N; The mol ratio of described raw material I and raw material II is 1:(1.0-1.5); Pd 2 (dba) 3 The molar ratio to raw material I is (0.006-0.02):1, the molar ratio of sodium tert-butoxide to raw material I is (2.0-3.0):1; the molar ratio of triphenylphosphine to raw material I is (2.0-3.0) : 1; 1g raw material I adds 50-100mL toluene.

[0075] Take the synthesis of intermediate N-1 as an example:

[0076]

[0077] Nitrogen was passed into a 250mL three-necked flask, and 0.01mol 4-aminobiphenyl, 0.012mol 4-bromobiphenyl, 0.03mol pot...

Embodiment 1-2

[0082] The preparation of embodiment 1-2 intermediate M

[0083]

[0084] Step 1: Dissolve raw material III and raw material IV in toluene, add Pd 2 (dba) 3 , triphenylphosphine and potassium tert-butoxide; under an inert atmosphere, react the mixed solution of the above reactants at 90-110°C for 10-24 hours, cool and filter the reaction solution, spin the filtrate, and pass the residue through a silica gel column , to obtain intermediate O; the mol ratio of the raw material III to the raw material IV is 1:(1.0-1.5); Pd 2 (dba) 3 The molar ratio to raw material III is (0.006-0.02):1, the molar ratio of sodium tert-butoxide to raw material III is (2.0-3.0):1; the molar ratio of triphenylphosphine to raw material III is (2.0-3.0) : 1; 1g raw material III adds 50-100mL toluene.

[0085] Step 2: Dissolve intermediate O and raw material V in toluene, add Pd 2 (dba) 3 , triphenylphosphine and potassium tert-butoxide; under an inert atmosphere, react the mixed solution of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com