Preparation method of morpholine ethanesulfonic acid

A technology of morpholineethanesulfonic acid and sodium morpholineethanesulfonate, which is applied in the field of ethanesulfonic acid derivative products, can solve the problems of high COD of crystallization centrifuged mother liquor, corrosion damage of production equipment, high cost of biochemical treatment, etc., and achieves improved acidification removal Effects of salt method, increased equipment life, and improved synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

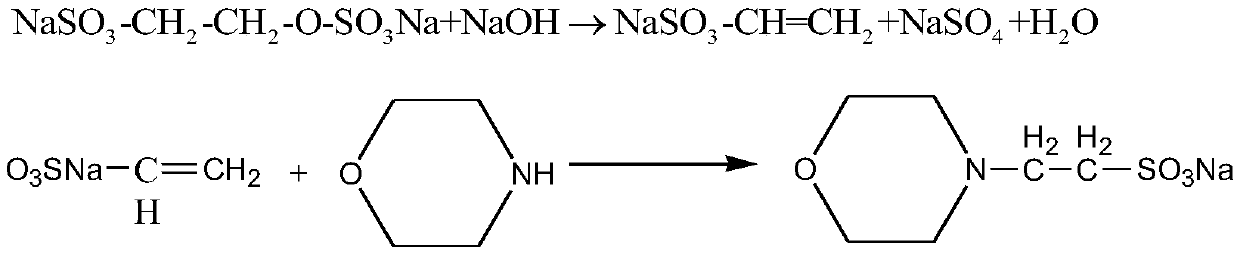

[0037] A kind of reaction formula of the preparation method of morpholineethanesulfonic acid is:

[0038] (1) Sulfonation

[0039] Main response:

[0040] side effects:

[0041] (2) Neutralization

[0042] Main response:

[0043] HSO 3 -CH 2 -CH 2 -O-SO 3 H+2NaOH→NaSO 3 -CH 2 -CH 2 -O-SO 3 Na+2H 2 o

[0044] side effects:

[0045] NaSO 3 -CH 2 -CH 2 -O-SO 3 Na+NaOH→NaSO 3 -CH=CH 2 +NaSO 4 +H 2 o

[0046] h 2 SO 4 +2NaOH→Na 2 SO 4 +2H 2 o

[0047] (3) Addition

[0048] Main response:

[0049]

[0050] side effects:

[0051]

[0052] (4) Acidification

[0053] Main response:

[0054]

[0055] side effects:

[0056]

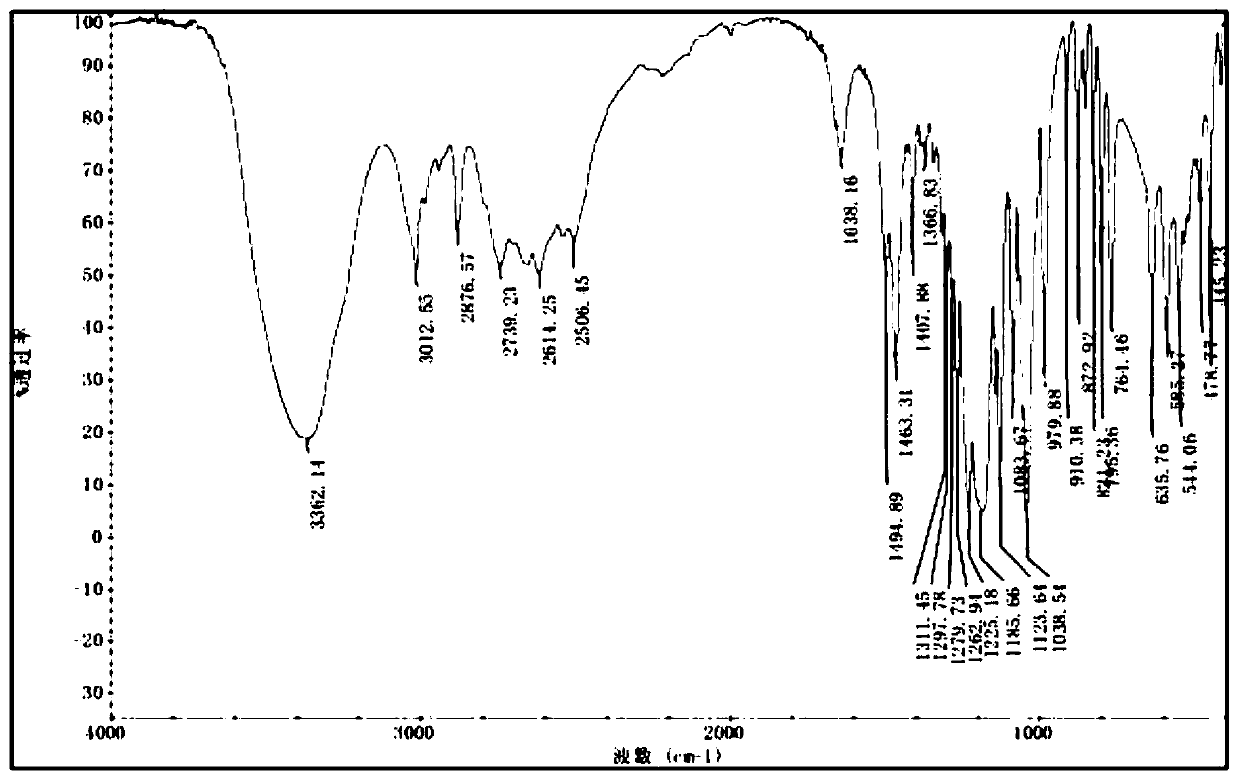

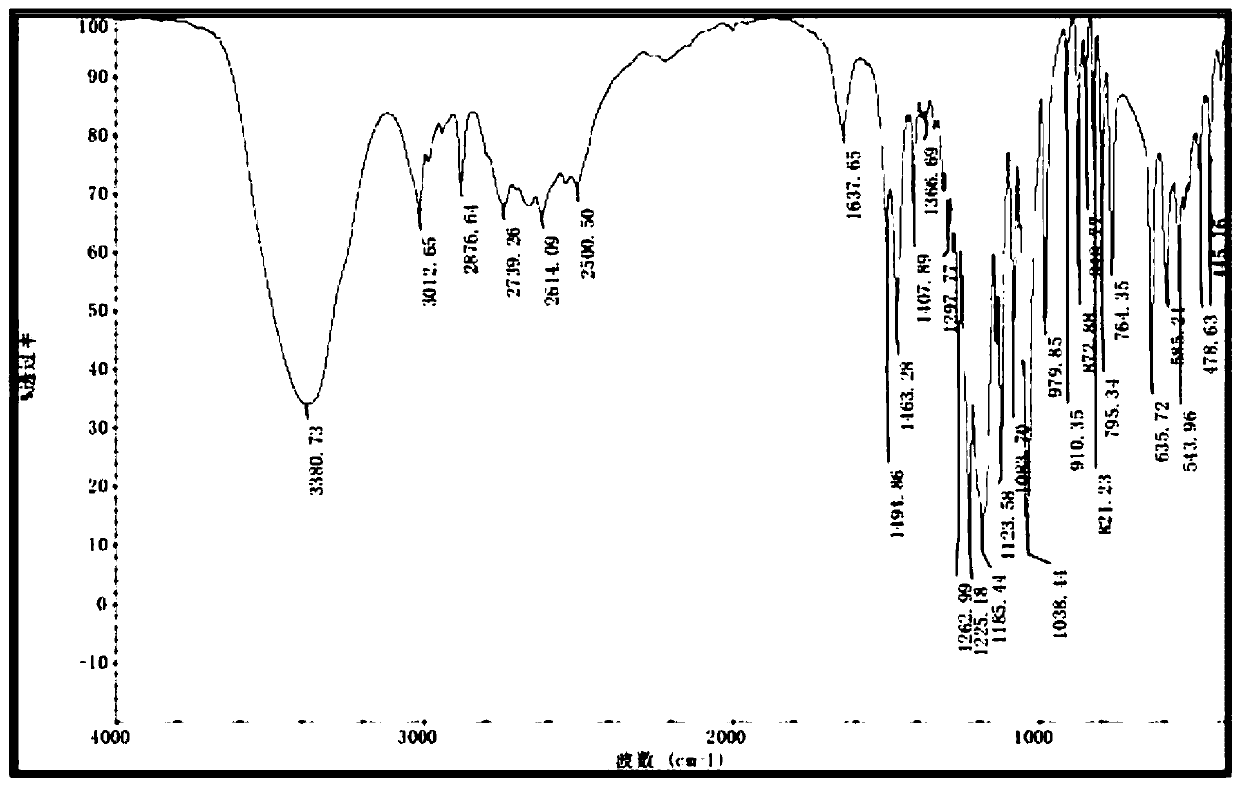

[0057] Infrared Qualitative Analysis figure 1 and figure 2 The match is 99.86%.

Embodiment 1

[0059] (1) Add 64.4g of absolute ethanol, and feed 224g of sulfur trioxide gas at 0-50°C under stirring and cooling to generate ethanedisulfonic acid;

[0060] (2) Add 284.4g of deionized water and drop ethanedisulfonic acid at 35-40°C to dilute;

[0061] (3) Add dropwise 30% liquid caustic soda 373.3g at 35-40°C under stirring and cooling down to generate sodium edisulphonate solution, add morpholine 121.8g under stirring, add 30% liquid caustic soda 186.7g dropwise at 60°C, control The pH of the reaction solution is 12.5-13.5. After the dropwise addition is completed, the temperature is kept at 60°C for 4 hours, the temperature is raised to 100°C and the temperature is kept at reflux for 4 hours, and the temperature is lowered to below 40°C;

[0062] (4) Add 142g of 49% dilute sulfuric acid dropwise to acidify to PH=4.3, add 400g of deionized water to dilute to a material content below 15%, cool to 10-20°C and centrifuge 386.4g of crystallized sodium sulfate decahydrate;

...

Embodiment 2

[0066] (1) Add 64.4g of absolute ethanol, and feed 224g of sulfur trioxide gas at 0-50°C under stirring and cooling to generate ethanedisulfonic acid;

[0067] (2) Add 284.4g of deionized water and drop ethanedisulfonic acid at 10-20°C to dilute;

[0068] (3) Add 30% liquid caustic soda 373.3g dropwise at 10-20°C under stirring and cooling to generate sodium edisulphonate solution, add morpholine 121.8g under stirring, add 30% liquid caustic soda 186.7g dropwise at 60°C, control The pH of the reaction solution is 12.5-13.5. After the dropwise addition is completed, the temperature is kept at 60°C for 8 hours, the temperature is raised to 100°C and the temperature is kept at reflux for 4 hours, and the temperature is lowered to below 40°C;

[0069] (4) Add 142g of 49% dilute sulfuric acid dropwise to acidify to PH=4.3, add 400g of deionized water to dilute to a material content below 15%, cool down to 10-20°C and centrifuge 382g of crystallized sodium sulfate decahydrate;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com