A system and preparation method for preparing methyl phosphite by using methylaluminum chloride

A technology of methyl phosphite and methyl aluminum chloride, applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc., can solve the problem of low product yield, increased side reactions, etc. The problem of high cost of product purification, to achieve the effect of improving the reaction rate, improving the production efficiency, and improving the simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0141] The preparation method comprises the following steps:

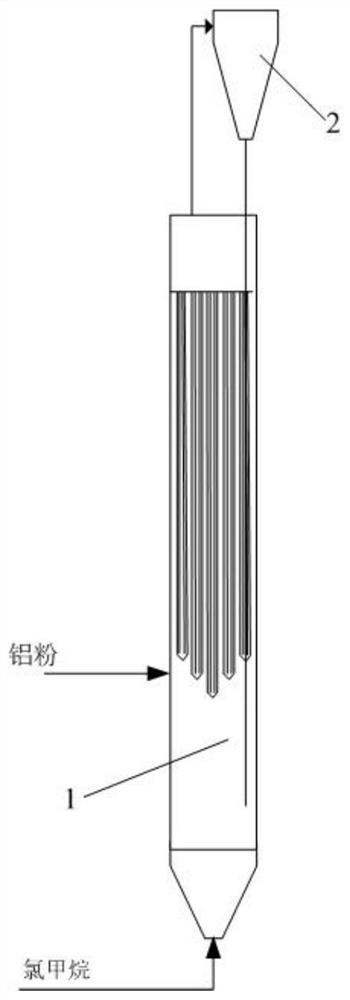

[0142] (a) raw material aluminum, catalyzer and gasified methyl chloride carry out gas-solid catalytic reaction in fluidized bed reactor 1, obtain mixed gas;

[0143] (b) the mixed gas that step (a) obtains obtains the methylaluminum chloride product after separation;

[0144] (c) The methylaluminum chloride product that step (b) obtains reacts with phosphorus trichloride in the synthesis unit 6 of methyl phosphorus dichloride to generate ligand 3CH 3 PCl 2 2AlCl 3 , and then react with an alkali metal halide to obtain methyl phosphorus dichloride;

[0145] (d) reacting the methyl phosphorus dichloride obtained in step (c) with alcohol to obtain a methyl phosphite product.

Embodiment 1

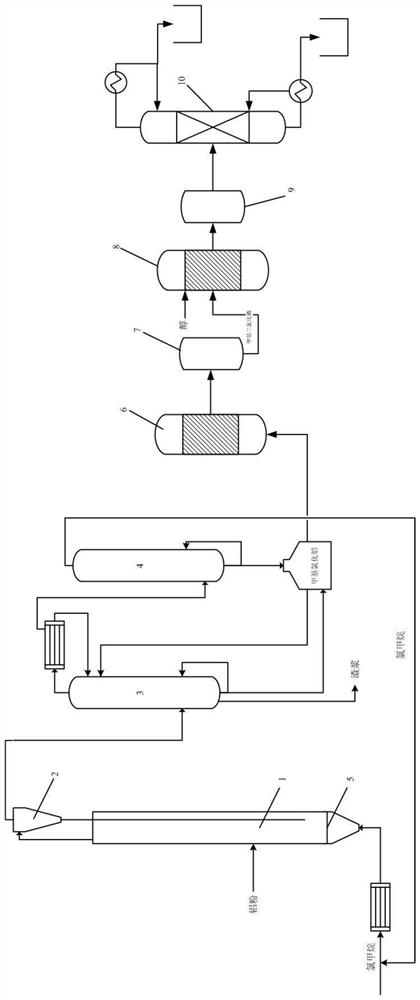

[0148] This embodiment provides a system for preparing methyl phosphite, such as figure 1 As shown, the system includes a methyl aluminum chloride synthesis unit, a methyl phosphorus dichloride synthesis unit and a methyl phosphite synthesis unit; the methyl aluminum chloride synthesis unit includes a fluidized bed reactor connected in sequence 1 and a separation unit, the methyl phosphorus dichloride synthesis unit includes a methyl phosphorus dichloride synthesis unit 6, and the methyl phosphorus dichloride synthesis unit 6 enters the separation for the product of the closed reactor fluidized bed reactor 1 The unit is separated, and the methylaluminum chloride obtained by the separation unit enters the methyl phosphorus dichloride synthesis unit 6 in the methyl phosphorus dichloride synthesis unit to react, and the methyl phosphorus dichloride synthesis unit obtains Phosphorous dichloride enters the synthesis unit of methyl phosphite;

[0149] Wherein, the bottom of the flu...

Embodiment 2

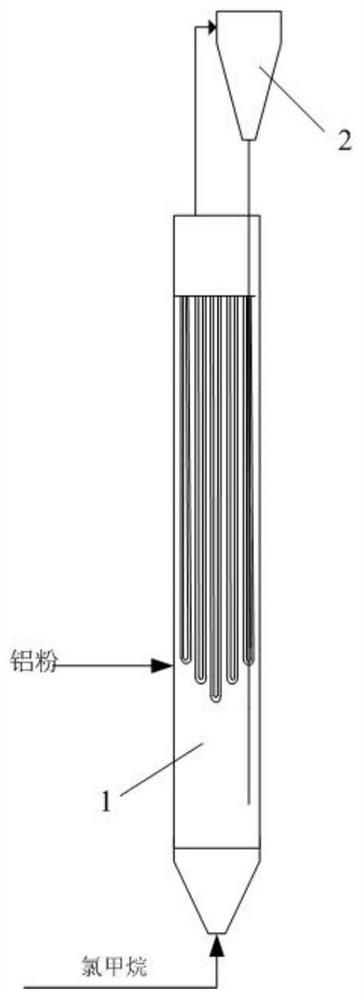

[0154] This embodiment provides a system for preparing methyl phosphite. The system structure refers to the system structure in Example 1, the difference is that the gas hole opening rate on the gas distributor 5 is 13.8%, and the fluidized bed reaction A U-shaped heat exchanger is set in the device 1, such as image 3 As shown, the U-shaped heat exchanger is placed above the gas distributor 6; the gas-solid separation device 2 is placed outside the fluidized bed reactor 1, and its solid material outlet is communicated from the outside of the fluidized bed reactor 1 to the Above the gas distributor in the fluidized bed reactor 1; the methyl phosphite synthesis unit 8 is a tubular reactor, and the deacidification unit 9 is a falling film evaporator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com