Environmental barrier coating and coating method and application thereof

An environmental barrier and coating technology, applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problems of further improvement of service time and low maximum service temperature, and achieve long service life and improved service life. Use performance and life, good service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The environmental barrier coating coating method provided in this embodiment has the following steps:

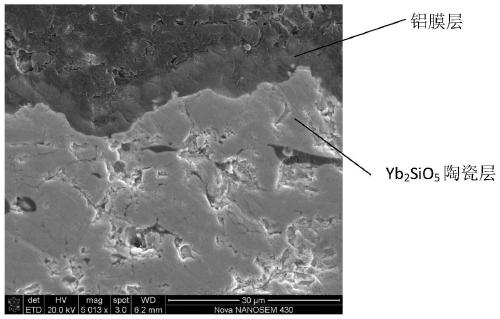

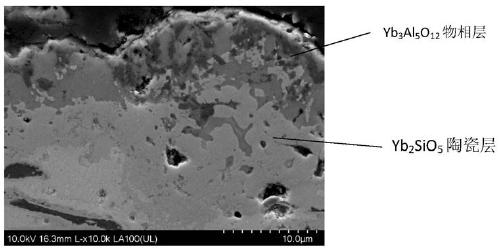

[0070] Using atmospheric plasma spraying to prepare Si, mullite, and Yb on the surface of silicon carbide-based composites 2 SiO 5 Coating, the thickness of the coating is 50μm, 50μm, 80μm; magnetron sputtering is used in Yb 2 SiO 5 An aluminum film layer with a thickness of 3μm is prepared on the coating surface. The conditions of magnetron sputtering are: magnetron target current 3A, bias voltage 150V; heat treatment of the environmental barrier coating deposited with aluminum film layer, the conditions of the heat treatment: 800 Keep temperature at ℃ for 2h, keep at 1300℃ for 24h, heating rate is 5℃ / min, vacuum oxygen partial pressure is less than 2×10 -3 Pa. After cooling to room temperature, an environmental barrier coating is obtained on the surface of the substrate.

Embodiment 2

[0072] The environmental barrier coating coating method provided in this embodiment has the following steps:

[0073] Plasma spraying-physical vapor deposition is used to prepare Si, mullite, and Yb on the surface of silicon carbide-based composites 2 SiO 5 Coating, the thickness of the coating is 50μm, 50μm, 80μm; magnetron sputtering is used in Yb 2 SiO 5 An aluminum film layer with a thickness of 3μm is prepared on the coating surface. The conditions of magnetron sputtering are: magnetron target current 3A, bias voltage 150V; heat treatment of the environmental barrier coating deposited with aluminum film layer, the conditions of the heat treatment: 700 Keep temperature at ℃ for 2h, keep at 1300℃ for 24h, increase / decrease rate is 10℃ / min, vacuum oxygen partial pressure is less than 2×10 -3 Pa. After cooling to room temperature, an environmental barrier coating is obtained on the surface of the substrate.

Embodiment 3

[0075] The environmental barrier coating coating method provided in this embodiment has the following steps:

[0076] Plasma spraying-physical vapor deposition is used to prepare Si, mullite, and Yb on the surface of silicon carbide-based composites 2 SiO 5 Coating, the thickness of the coating is 50μm, 50μm, 80μm; magnetron sputtering is used in Yb 2 SiO 5 An aluminum film layer with a thickness of 2μm is prepared on the surface of the coating. The conditions of magnetron sputtering are: magnetron target current 3A, bias voltage 150V; heat treatment of the environmental barrier coating deposited with aluminum film layer, the conditions of heat treatment: 700 ℃ heat preservation for 2h, 1350℃ heat preservation for 20h, heating rate is 10℃ / min, vacuum oxygen partial pressure is less than 2×10 -3 Pa. After cooling to room temperature, an environmental barrier coating is obtained on the surface of the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com