An etching solution composition for silver-containing layer and a manufacturing method for an array substrate for display device using the same

A technology of etching solution and composition, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, electric solid-state devices, etc., can solve the problems of decreased stability over time, and achieve improved stability over time, reduction of silver residue and re-adsorption , silver residue and excellent re-adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

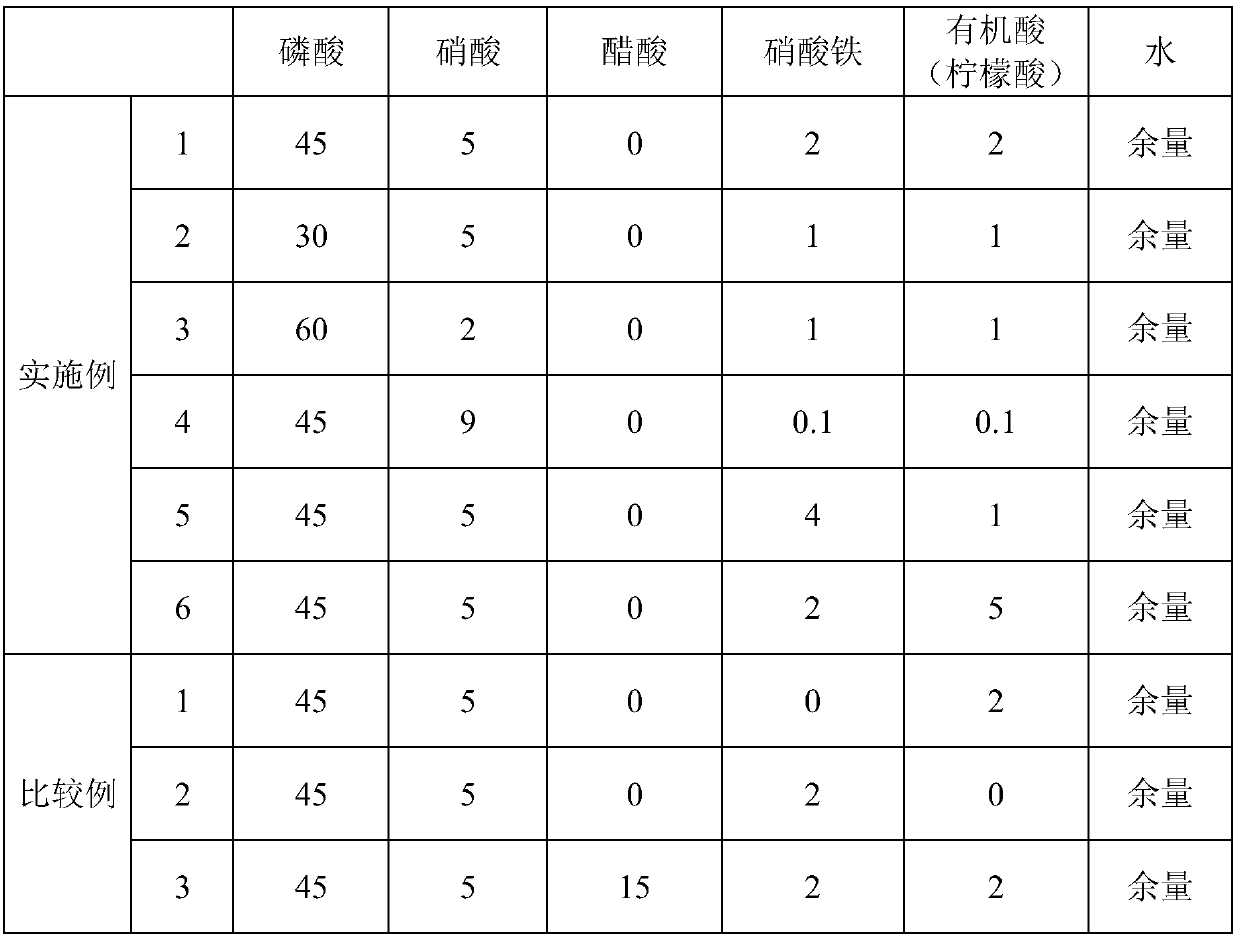

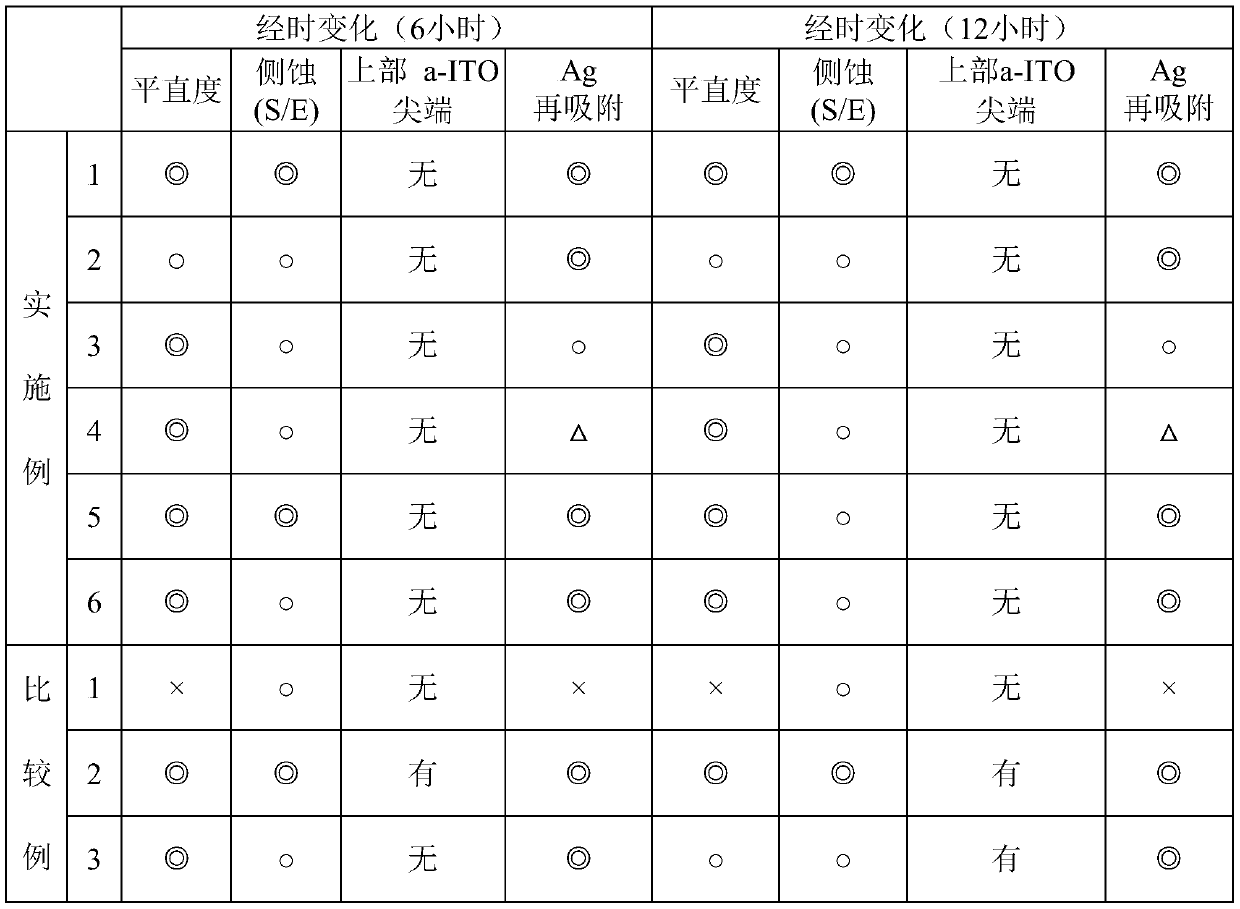

[0049] By depositing an organic insulating film on the substrate, and on the insulating film with A three-layer film of ITO / Ag / ITO was deposited to form a plate, and the plate was cut into 500×600 mm with a diamond knife to prepare a sample.

[0050] The performance test was performed in the following manner using the etching solution compositions of the above-mentioned Examples 1-6 and Comparative Examples 1-3.

experiment example 1

[0051] Experimental example 1: About the effect of flatness

[0052] Add the etching solution compositions of the above-mentioned Examples 1 to 6 and Comparative Examples 1 to 3 respectively into the experimental equipment of the jet etching method (model name: ETCHER (TFT), K.C. Tech Company), and set the temperature to 40°C Afterwards, the temperature is raised, and then the spray etching equipment is operated after the temperature reaches 40±0.1° C., so that the etching solution is continuously circulated in the spray etching equipment. The etching process of the sample was performed at the time of 6 hours and the time of 12 hours after the temperature reached 40±0.1° C., respectively.

[0053] The total etching time was set to 85 seconds and implemented.

[0054] Spraying was started after placing the substrate, and after 85 seconds of etching time had elapsed, the substrate was taken out, washed with deionized water, and then dried with a hot air drying device. After cl...

Embodiment 2

[0059] Example 2: Measuring the side erosion distance

[0060] Add the etching solution compositions of the above-mentioned Examples 1 to 6 and Comparative Examples 1 to 3 respectively into the experimental equipment of the jet etching method (model name: ETCHER (TFT), K.C. Tech Company), and set the temperature to 40°C Afterwards, the temperature is raised, and then the spray etching equipment is operated after the temperature reaches 40±0.1° C., so that the etching solution is continuously circulated in the spray etching equipment. The etching process of the sample was performed at the time of 6 hours and the time of 12 hours after the temperature reached 40±0.1° C., respectively. The total etching time was set to 85 seconds and implemented.

[0061] Spraying was started after placing the substrate, and after 85 seconds of etching time had elapsed, the substrate was taken out, washed with deionized water, and then dried using a hot air drying device. The substrate was cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com