Drilling fluid circulation system for reducing drilling trip-out suction pressure

A technology of circulation system and drilling fluid, applied in the automatic control system of drilling, drilling equipment, wellbore/well components, etc., can solve the problems of prolonging the exposure time of the open-hole section, increasing the risk of wellbore instability, and increasing the cost of drilling time. , to reduce the risk of wellbore instability, reduce tripping time, and reduce drilling costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

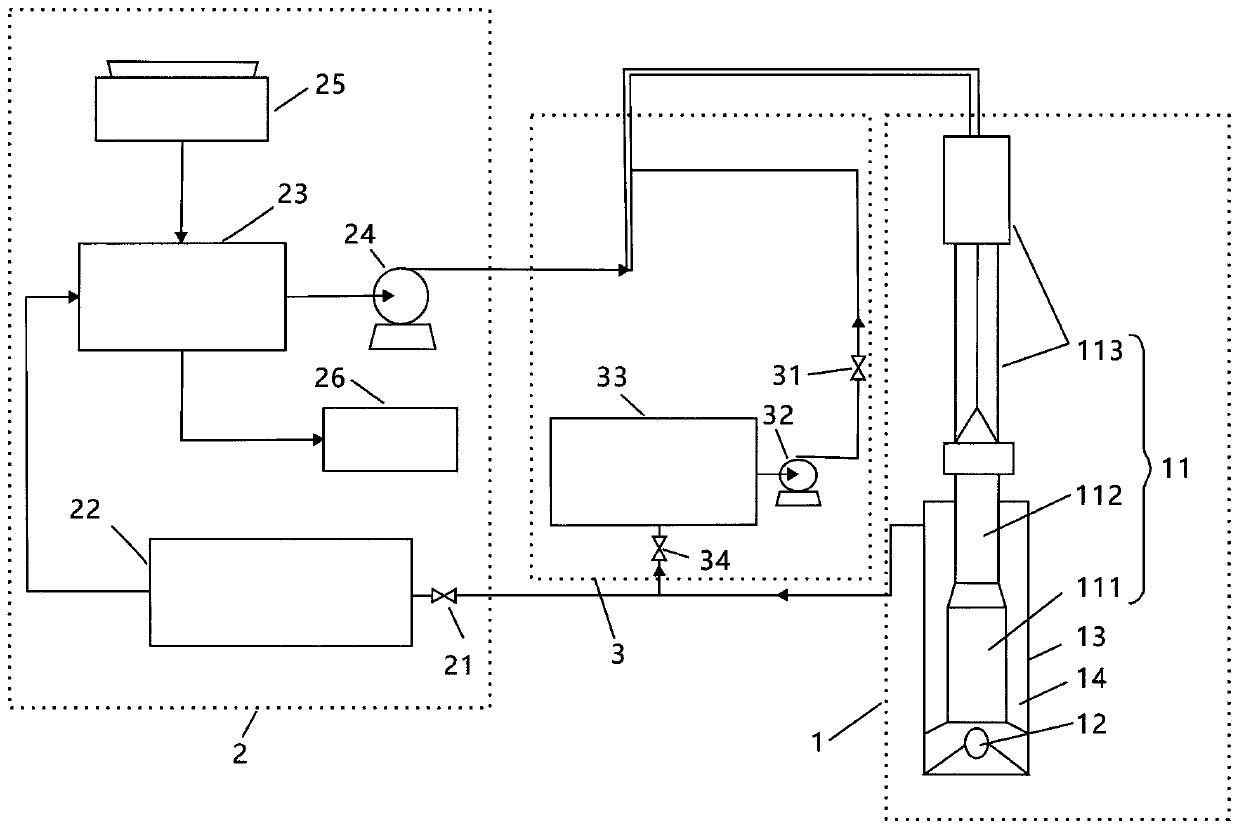

[0025] See figure 1 The embodiment of the present invention provides a drilling fluid circulation system for reducing the suction pressure of drilling and tripping, which includes: a drilling tool assembly 1 , a normal drilling circulation channel 2 and a tripping circulation channel 3 .

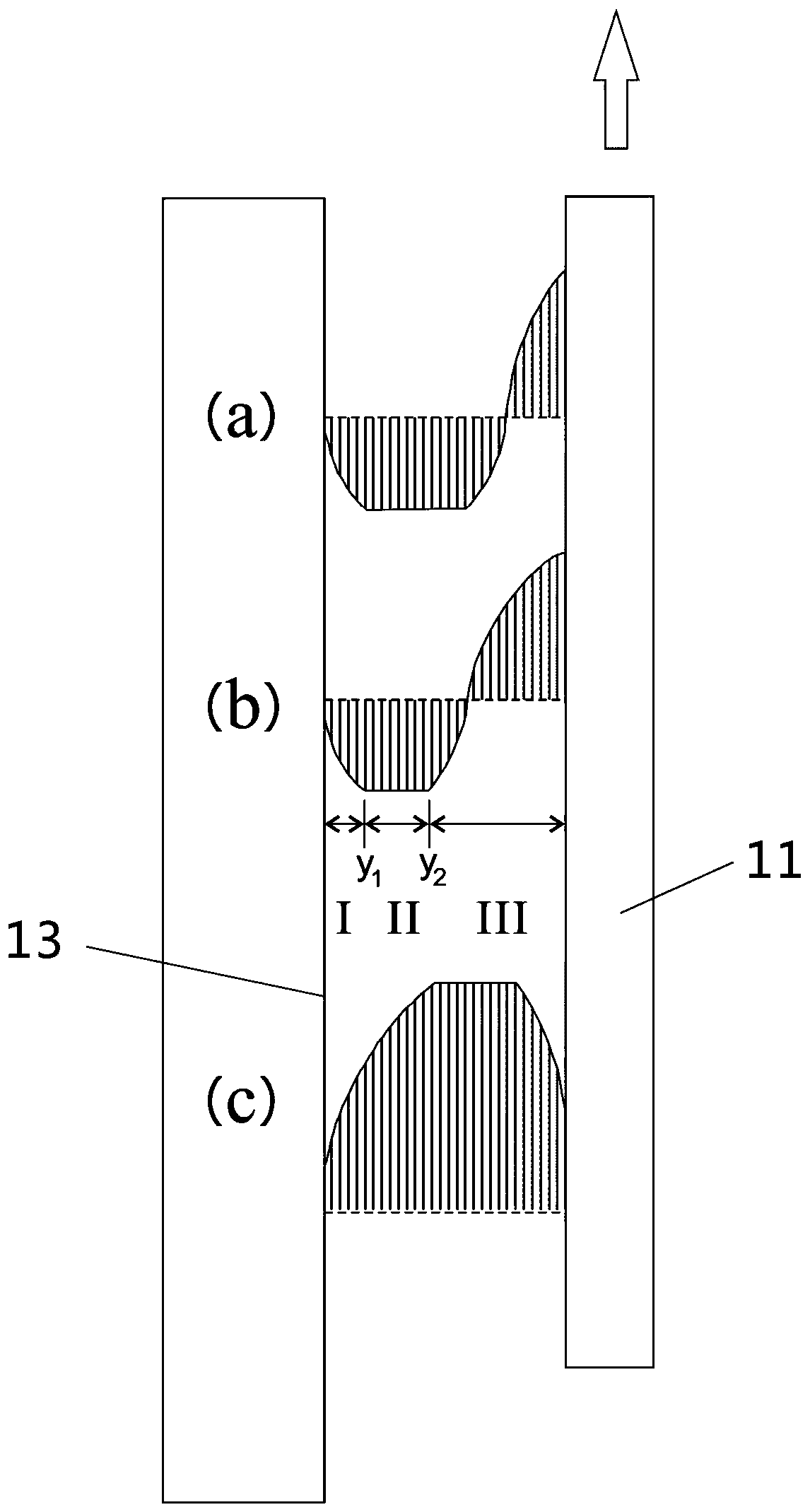

[0026] See figure 1 , the drilling tool assembly 1 is used to drill the formation, including a drill string 11 and a drill bit 12, the drill string 11 is hollow with two ends open, and is used to transport drilling fluid from the surface to the bottom of the well, and the drill bit 12 It is fixedly arranged at one end of the drill string 11. The outer sidewall of the drill string 11 and the inner sidewall 13 of the wellbore form an annular space 14, and the annular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com