Catalyst for synthesizing diisooctyl phthalate plasticizer and preparation method and application of catalyst

A technology of diisooctyl phthalate and catalyst is applied to the catalyst for synthesizing diisooctyl phthalate plasticizer and the field of preparation thereof, and can solve the problems of high separation difficulty, low esterification rate, cumbersomeness and the like , to reduce the reaction temperature, improve the esterification rate, and achieve the effect of light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

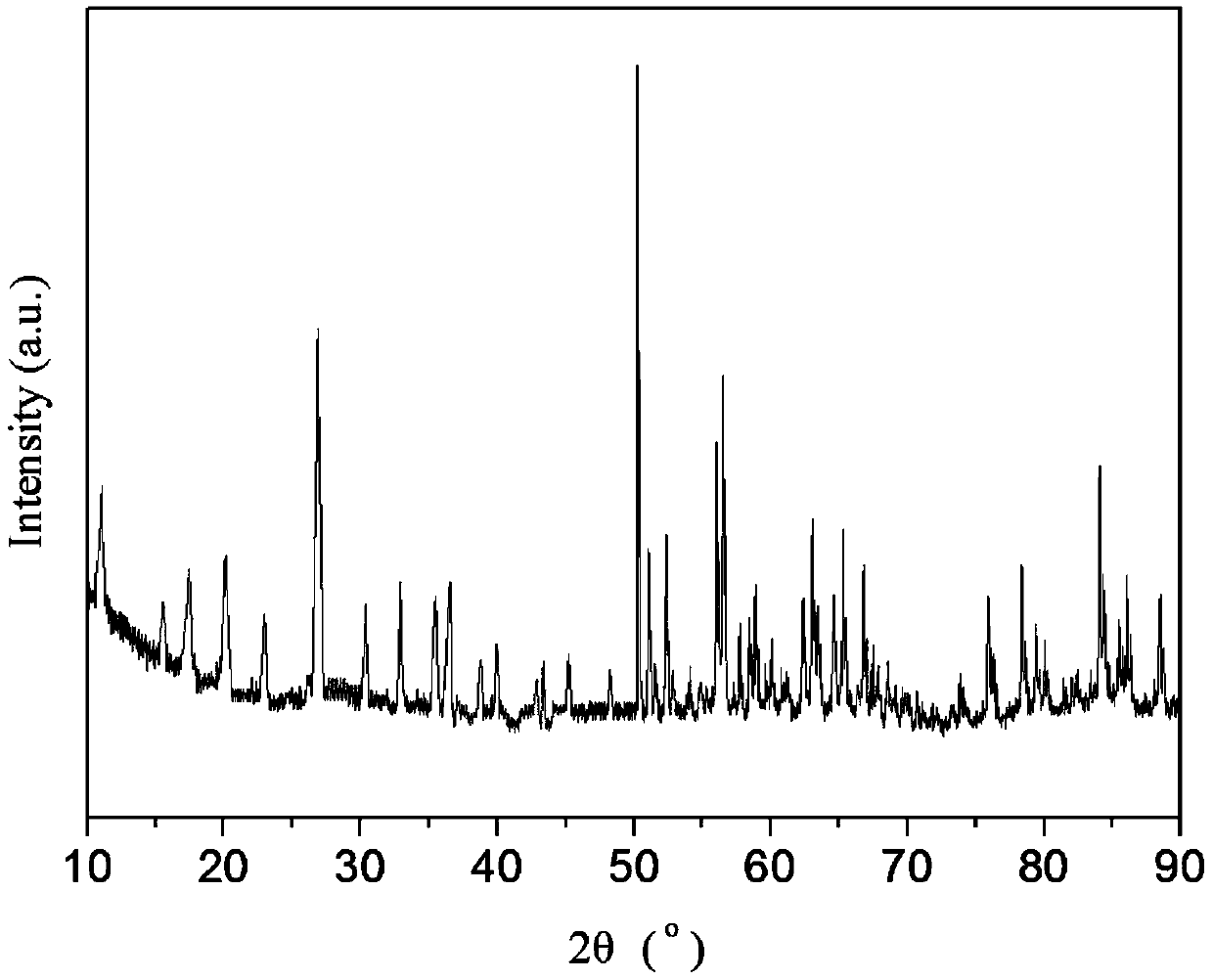

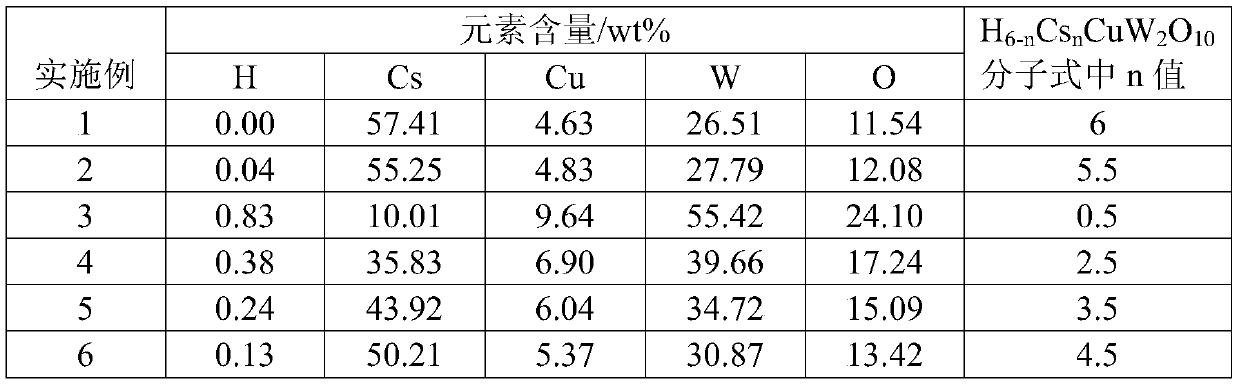

[0025] Dissolve 11.7g of cesium nitrate (0.06mol) and 6.0g of copper tungstic acid (0.01mol) in 50mL of deionized water, stir and mix evenly, pour into a hydrothermal reactor, react at 100°C for 12h, and then the reaction product Cool to room temperature, filter, and dry the obtained solid to obtain the copper cesium tungstate catalyst. The XRF characterization results are shown in Table 1. It is determined by XRF characterization that n=6 in the molecular formula, that is, the catalyst is Cs 6 wxya 2 o 10 .

[0026] Add 13.0g isooctyl alcohol and 7.4g phthalic anhydride (molar ratio 2:1) into a four-necked flask with a reflux condenser, then add 0.5g (2.5%) of Cs 6 wxya 2 o 10 Catalyst, flow rate is 5mL / min nitrogen protection, heating to 100 ° C, after stirring for 4h, stop heating and stirring, vacuum distillation to remove the remaining iso-octanol, filter to remove the catalyst, to obtain di-isooctyl phthalate, Through high-performance liquid chromatography analysis...

Embodiment 2

[0028] Dissolve 10.7g of cesium nitrate (0.055mol) and 6.0g of copper tungstic acid (0.01mol) in 60mL of deionized water, stir and mix evenly, pour into a hydrothermal reactor, react at 120°C for 24h, and then the reaction product Cool to room temperature, filter, and dry the obtained solid to obtain the copper cesium tungstate catalyst. The XRF characterization results are shown in Table 1. It is determined by XRF characterization that n=5.5 in the molecular formula, that is, the catalyst is H 0.5 Cs 5.5 wxya 2 o 10 .

[0029] Add 22.8g of isooctyl alcohol and 7.4g of phthalic anhydride (molar ratio 3.5:1) into a four-necked flask with a reflux condenser, then add 0.3g (1%) of H 0.5 Cs 5.5 wxya 2 o 10 The catalyst was protected by nitrogen with a flow rate of 10mL / min, heated to 130°C, stirred for 6 hours, then stopped heating and stirring, distilled under reduced pressure to remove the remaining isooctyl alcohol, and filtered to remove the catalyst to obtain diisoocty...

Embodiment 3

[0031] Dissolve 1.0g of cesium nitrate (0.005mol) and 6.0g of copper tungstic acid (0.01mol) in 70mL of deionized water, stir and mix evenly, pour into a hydrothermal reactor, react at 120°C for 24h, and then the reaction product Cool to room temperature, filter, and dry the obtained solid to obtain the copper cesium tungstate catalyst. The XRF characterization results are shown in Table 1. It is determined by XRF characterization that n=0.5 in the molecular formula, that is, the catalyst is H 5.5 Cs 0.5 wxya 2 o 10 .

[0032] Add 15.6g isooctyl alcohol and 7.4g phthalic anhydride (molar ratio 2.4:1) into a four-necked flask with a reflux condenser, then add 0.4g of H 5.5 Cs 0.5 wxya 2 o 10 The catalyst was protected by nitrogen gas with a flow rate of 8mL / min, heated to 130°C, and stirred for 4 hours, then the heating and stirring were stopped, the remaining isooctyl alcohol was removed by distillation under reduced pressure, and the catalyst was removed by filtration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com