Production method and device of novel green and environment-friendly methionine hydroxyl analogue complex metal salt

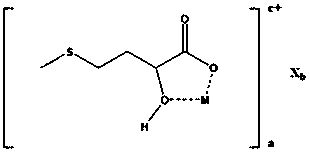

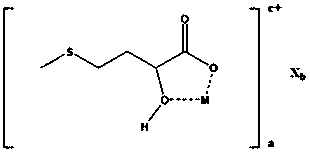

A technology of methionine hydroxyl and metal complexation, which is applied in the field of organic complex preparation, can solve the problems of low complexation rate and product impact, and achieve the effects of low production cost, increased stability and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

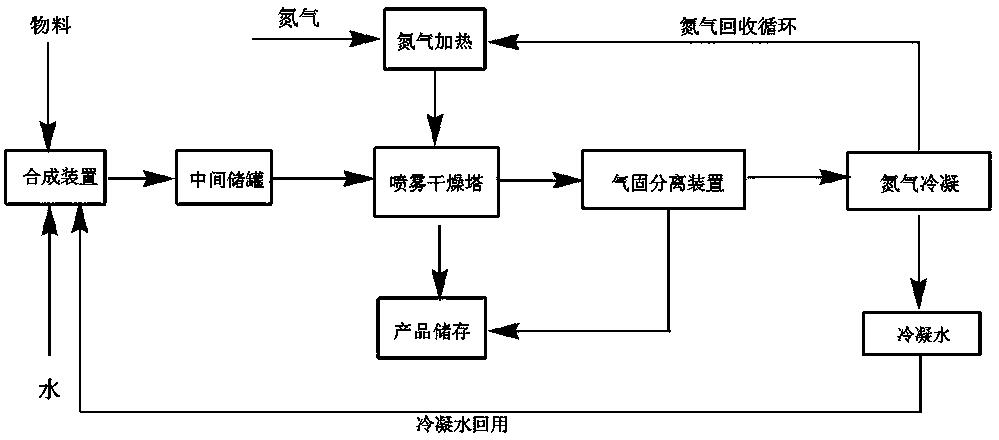

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of Methionine Hydroxyl Analog Complex Zinc Salt

[0038] Hydrolysis reaction of methionine hydroxyl analog dimer and multimer: add 340.9kg content of 88% methionine hydroxyl analog (2000 moles, monomer content 65%, dimer content 20%, polymer content Body content 3%) and 300kg of deionized water, then heated to 85 ° C, stirred and kept for 4 hours, sampling analysis, the total percentage content of dimers and polymers of methionine hydroxyl analogs was 0.08%, and methionine hydroxyl analogs The monomer content is 46.73%.

[0039] Complexation reaction of methionine hydroxyl analogs with zinc salt: Add 362.63kg (2000 moles) of zinc sulfate monohydrate with a content of 99% to the above reaction kettle under stirring, stir to dissolve completely, immediately raise the temperature to 95°C, and keep warm for 1.5 Hours, then add 434.92kg of zeolite powder, fully stir and mix evenly to obtain a solid content of 73.43%, which has good fluidity at 90°C.

...

Embodiment 2

[0045] Example 2 Preparation of Methionine Hydroxyl Analog Complex Copper Salt

[0046] Hydrolysis reaction of methionine hydroxy analog dimer and multimer: add 340.9kg content of 88wt% methionine hydroxy analog (2000 moles, monomer content 65wt%, dimer content 20wt%, polymer content of 3wt%) and 300kg of deionized water, then heated up to 85°C, stirred and kept warm for 4 hours to obtain an aqueous solution of methionine hydroxy analogs, sampling analysis, and the percentage content of dimers and polymers of methionine hydroxy analogs is 0.02wt%, and the content of 2-hydroxy-4-methylthiobutyric acid in the aqueous solution is 46.73wt%.

[0047] Complexation reaction of methionine hydroxyl analogs with copper salts: under stirring, add 505.05kg (2000 moles) of copper sulfate pentahydrate with a content of 99wt% to the above reaction kettle, stir to dissolve completely, immediately raise the temperature to 95°C, and keep warm for 1.5 hour, then add 432.00kg of zeolite powder, ...

Embodiment 3

[0049] Example 3 Preparation of Methionine Hydroxyl Analog Complex Cobalt Salt

[0050]Hydrolysis reaction of methionine hydroxy analog dimer and multimer: add 340.9kg content of 88wt% methionine hydroxy analog (2000 moles, monomer content 65wt%, dimer content 20wt%, polymer Body content 3wt%) and 300kg of deionized water, then heated up to 85 ° C, stirred and kept for 4 hours, sampling analysis, the percentage content of dimers and polymers of methionine hydroxyl analogs totaled 0.02wt%, and methionine was obtained An aqueous solution of hydroxy analogs, the content of 2-hydroxy-4-methylthiobutyric acid in the aqueous solution is 46.73wt%.

[0051] Complexation reaction of methionine hydroxyl analogs and cobalt salts: under stirring, add 567.98kg (2000 moles) of cobalt sulfate heptahydrate with a content of 99wt% to the above reaction kettle, stir to dissolve completely, immediately raise the temperature to 95°C, and keep warm for 1.5 hour, then add 370kg of zeolite powder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com