Product design and production process of anti-static moisture absorption and sweat releasing color weaving fabric

A technology of moisture absorption and perspiration, product design, applied in the field of blended fabric production, can solve problems such as negative impact on human health, accumulation of static electricity, and electrostatic clothing that is easy to absorb and carry viruses, bacteria, dust and harmful substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

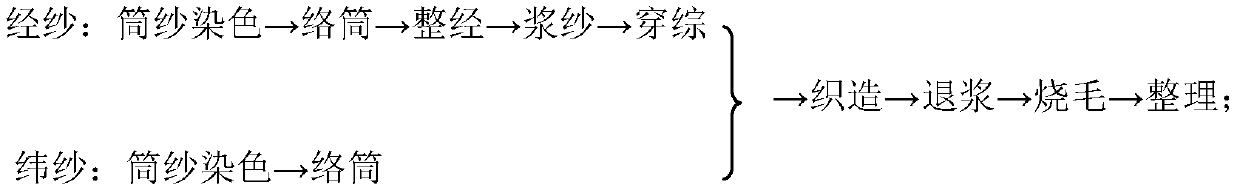

[0042] A product design and production process of an antistatic, moisture-absorbing and sweat-wicking yarn-dyed interwoven fabric, comprising the following steps:

[0043] S1: Selection of yarn raw materials

[0044] The warp yarn is 11.8tex polylactic acid / modal fiber blended yarn, wherein the polylactic acid fiber blended ratio is 55%, and the modal fiber blended ratio is 45%;

[0045]The weft yarn is 11.8tex vinylon / cupro blended yarn, wherein the blended ratio of vinylon fiber is 50%, and the blended ratio of cupro fiber is 50%;

[0046] S2: Product Design

[0047] a. Fabric design

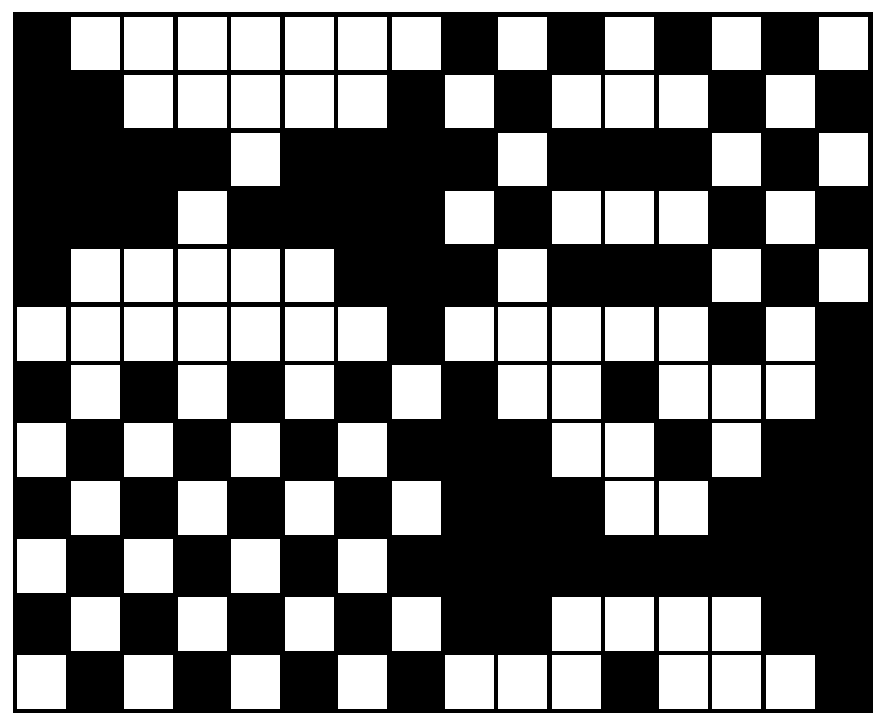

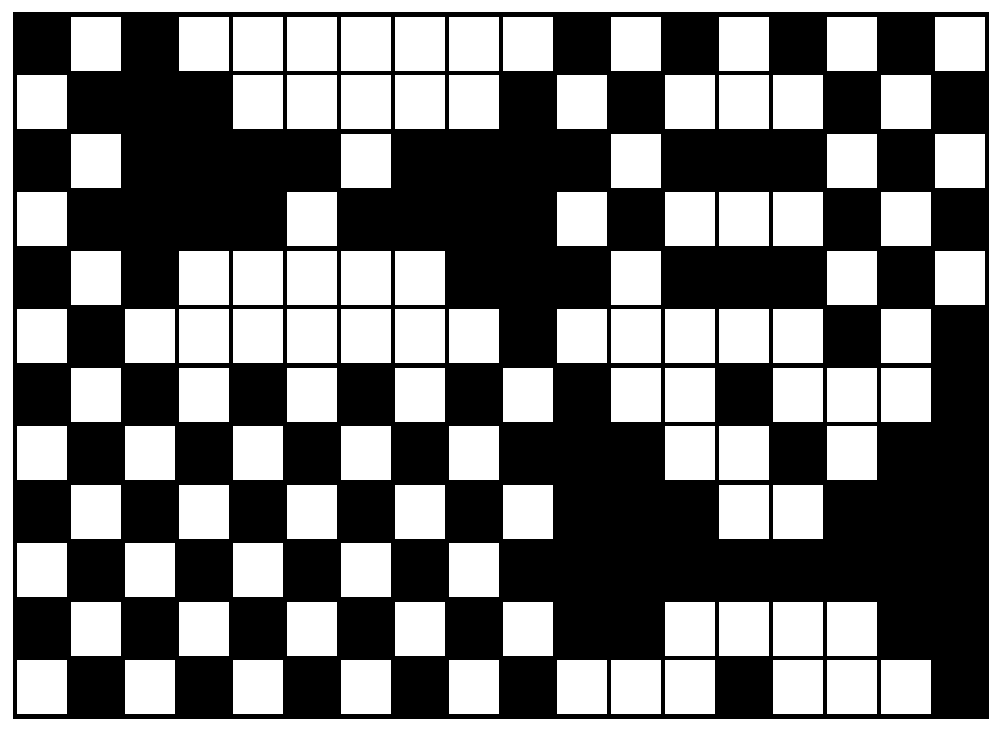

[0048] Plain weave is used for side weave, plain weave and small pattern are used for ground weave; see fabric weave diagram figure 1 ;

[0049] b. On-machine process design

[0050] Heald: 18 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com